Flue gas recirculation-based wide load-wide coal deep denitrification system for CFB (circulating fluidized bed) boiler

A flue gas recirculation and recirculation technology, which is applied in circulating fluidized bed boilers and circulating fluidized bed boilers in the field of wide load and wide coal type deep denitrification, which can solve the problems of increased NOx generation, reduced SNCR denitrification efficiency, ash plugging, etc. problems, to achieve the effect of reducing NOx emissions, improving air distribution in the furnace, and avoiding corrosion and ash plugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

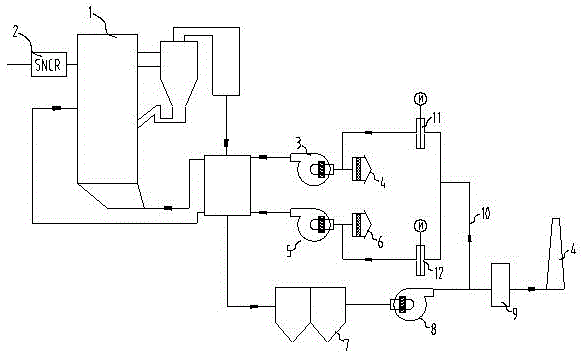

[0026] figure 1 It is a CFB boiler wide load-wide coal type deep denitrification system based on flue gas recirculation. The wide load-wide coal type deep denitrification system consists of a circulating fluidized bed boiler (1), an SNCR system (2), and a primary air blower (3) , primary air muffler (4), secondary air blower (5), secondary air muffler (6), dust collector (7), induced draft fan (8), desulfurization tower (9), recirculation flue (10 ), a primary air recirculation regulating door (11), and a secondary air recirculating regulating door (12).

[0027] One end of the recirculation flue (10) is connected to the flue between the induced draft fan (8) and the desulfurization tower (9), and the other end passes through the primary air recirculation adjustment door (11) and the secondary air recirculation adjustment door (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com