Temperature control low-nitrogen and energy-saving combustion device capable of achieving flue gas recirculation and staged premixed combustion

A premixed combustion and combustion device technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve the problems of unreasonable use of energy and turning a blind eye

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

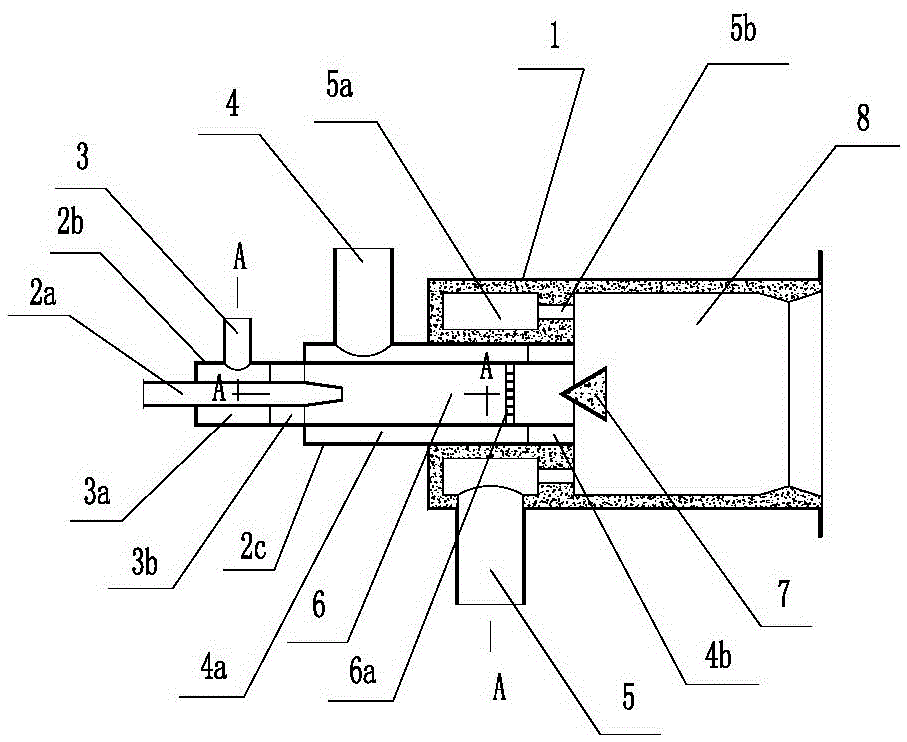

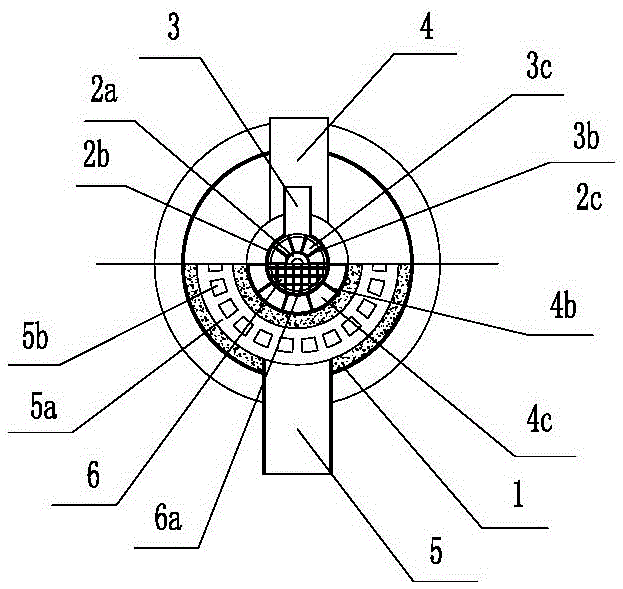

[0009] Such as figure 1 and figure 2 As shown, the present invention includes a combustion chamber 1 with one end closed and one end open. The open end of the combustion chamber has a mixed combustion space 8 built in. One end of the mixed combustion space is closed and the other end is open. The open end of the mixed combustion space and the opening of the combustion chamber The open end of the combustion chamber is the air flow outlet. The closed end of the mixed combustion space has a staged combustor extending through the closed end of the combustion chamber into the combustion chamber and connected with the mixed combustion space. The staged burner passes through the closure of the combustion chamber. The end that extends into the combustion chamber is the inner end, and the other end is the outer end. The closed end of the combustion cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com