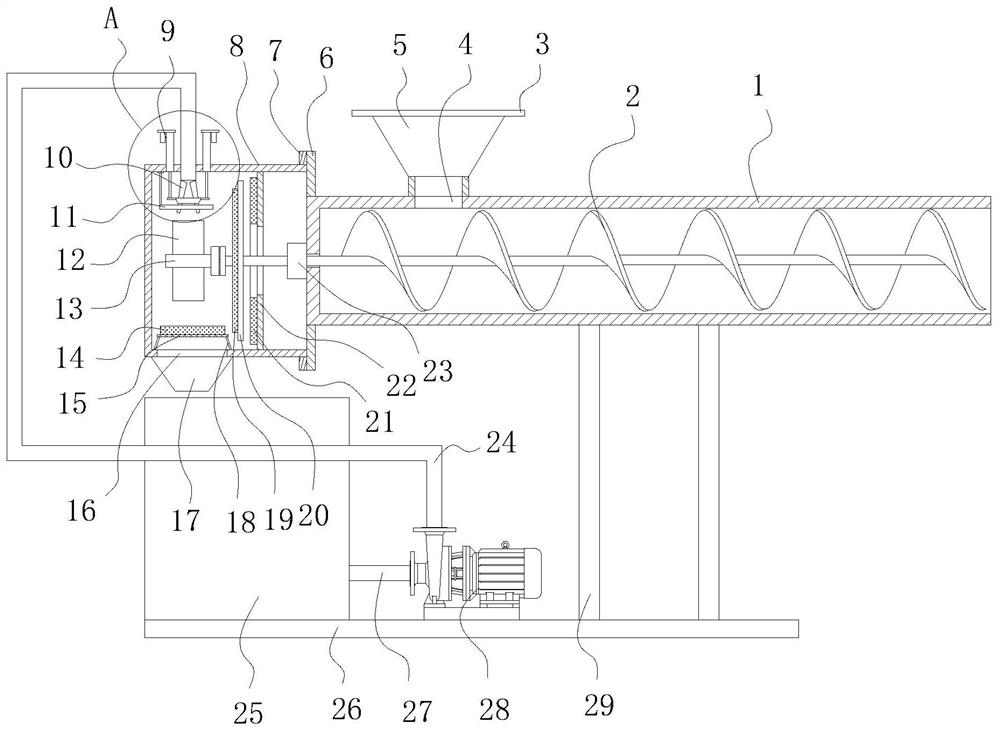

Industrial solid waste treatment system

A solid waste, treatment system technology, applied in the direction of combustion method, lighting and heating equipment, combustion type, etc., can solve the problems of damage, high temperature of motor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

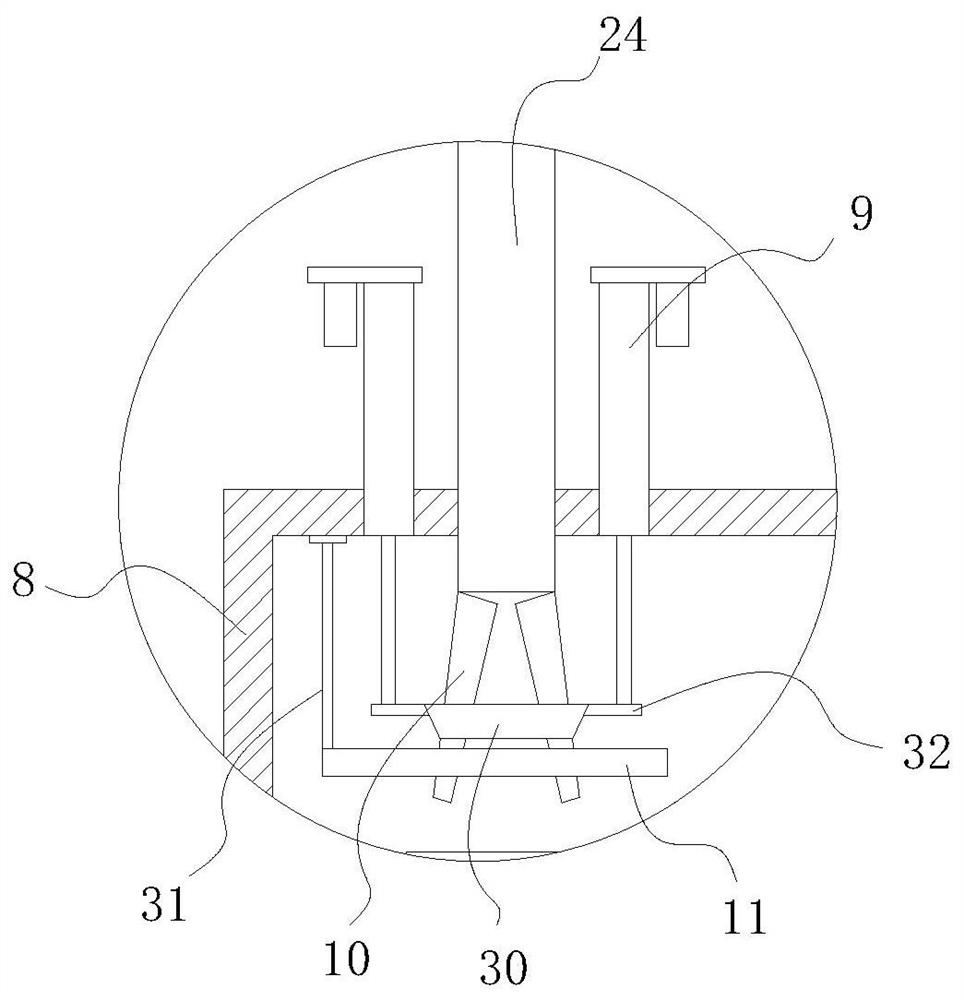

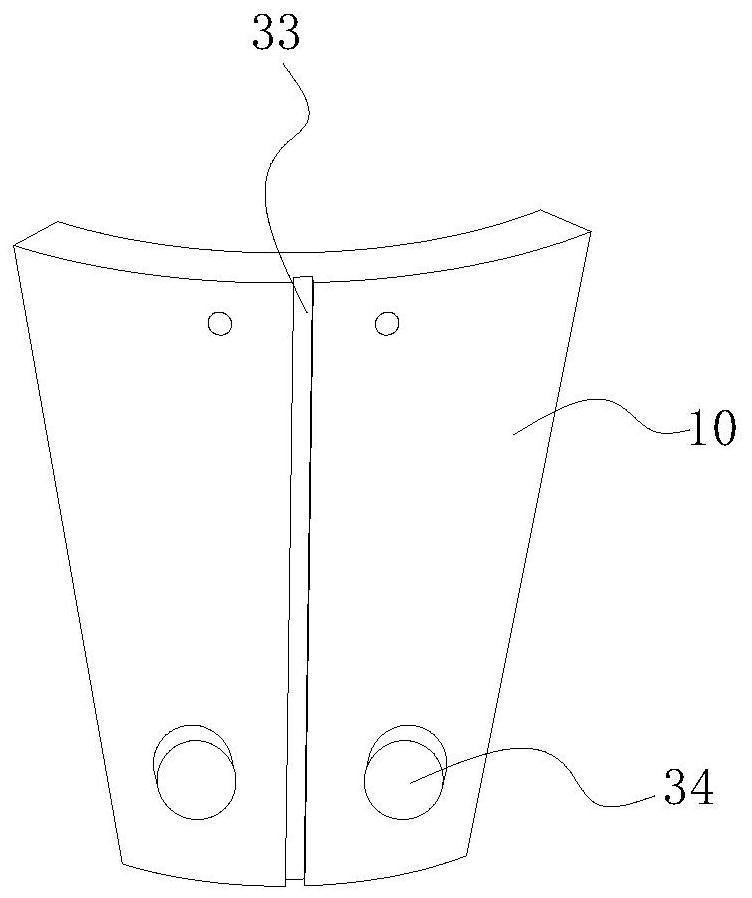

[0039] Specific implementation method: After connecting the circuit of the high-pressure water pump 28, the high-pressure water pump 28 pumps the water in the water storage tank 25 to the water delivery pipe 24, and then the water in the water delivery pipe 24 impacts on the water-retaining blade 12 at a high speed, thereby retaining the water The blade 12 drives the transmission rod 13 to rotate, and the transmission rod 13 drives the screw conveying blade 2 to rotate in the slag discharge barrel 1, and then the waste slag falling into the slag discharge is discharged under the push of the screw conveying blade 2, realizing the use of high-pressure water impact to drive the screw conveying The purpose of the rotation of the blade 2 is to prevent the heat from damaging the driving equipment. The water flowing into the cylinder 8 flows into the water leakage funnel 17 through the water outlet 16, and then the water is collected by the water leakage funnel 17 into the water storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com