A kind of purification equipment for ammonia in liquid sodium cyanide

A kind of purification equipment and sodium cyanide technology, which is applied in the direction of ammonia preparation/separation, liquid degassing, metal cyanide, etc., and can solve the problems of small contact area, decreased deamination degree of liquid sodium cyanide, and slow ammonia gas emission rate, etc. problem, to achieve the effect of increasing the contact area, increasing the volatilization rate, and increasing the deamination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

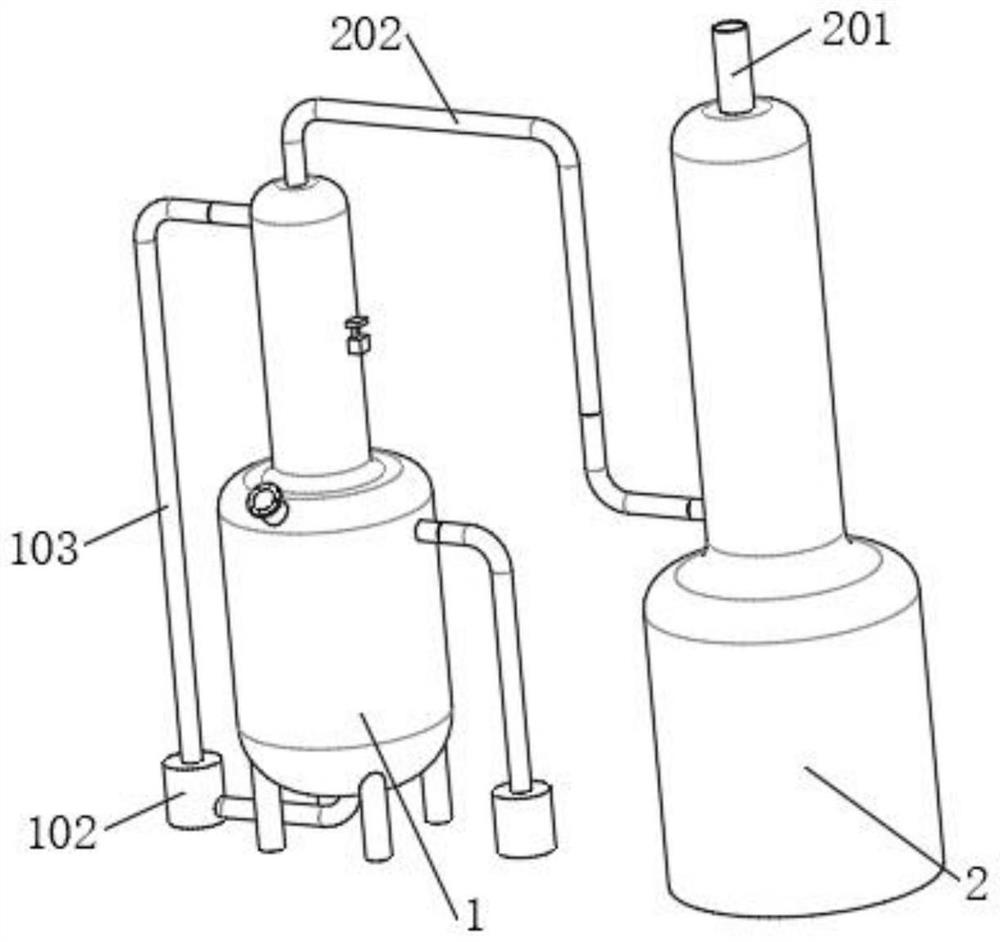

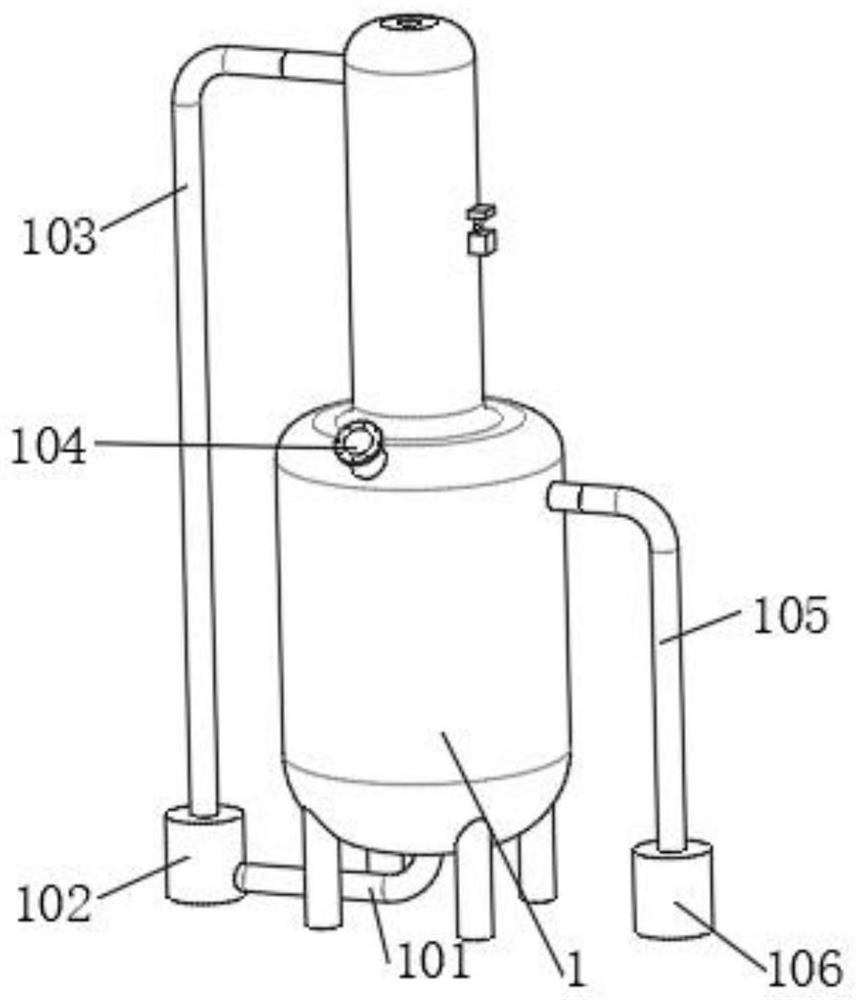

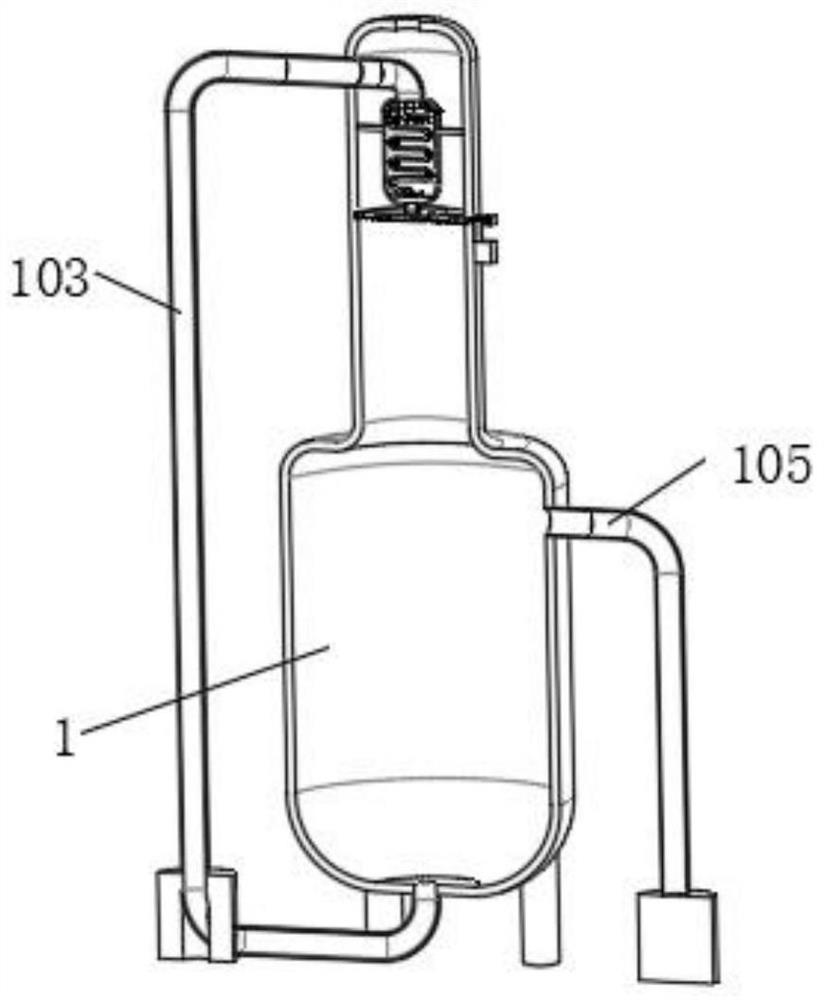

[0060]The embodiment of the present invention provides a kind of purification equipment for ammonia in liquid sodium cyanide, please refer to the attached Figure 1-2 , including: a deammonization tower 1, a purification tower 2 and a heating mechanism.

[0061] A liquid outlet is provided at the bottom of the deamination tower 1 , and the liquid outlet is fixedly connected with a liquid outlet pipe 101 . The end of the outlet pipe 101 away from the deamination tower 1 is fixedly connected with a circulating water pump 102 . The water outlet end of the circulating water pump 102 is fixedly connected with a main pipe 103 , and the end of the main pipe 103 away from the circulating water pump 102 passes through the side wall of the top of the deammonization towe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com