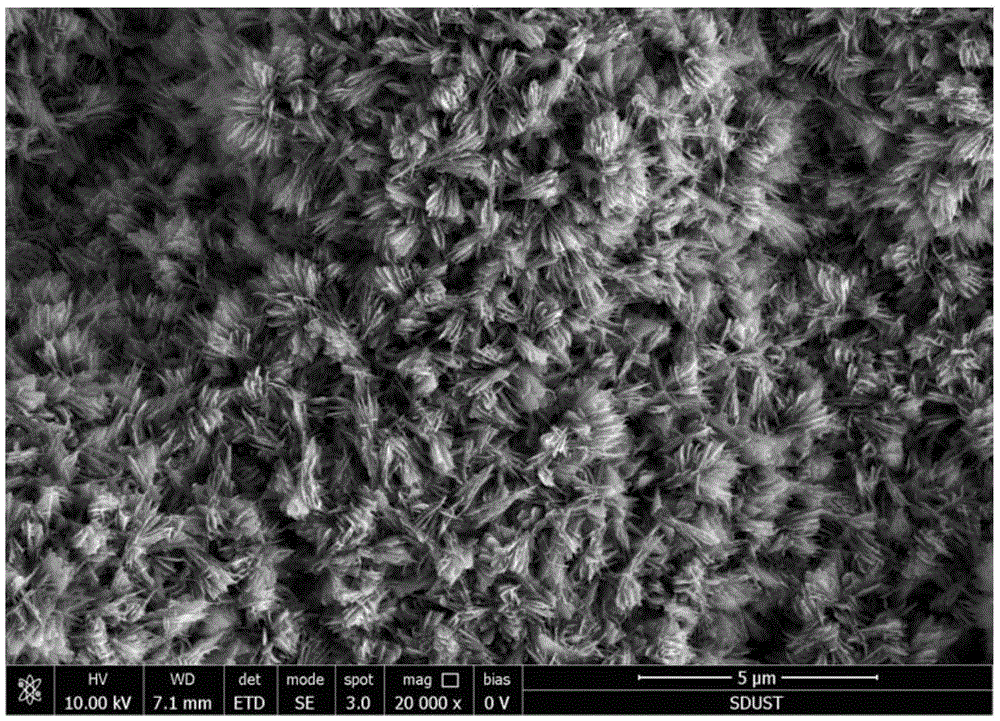

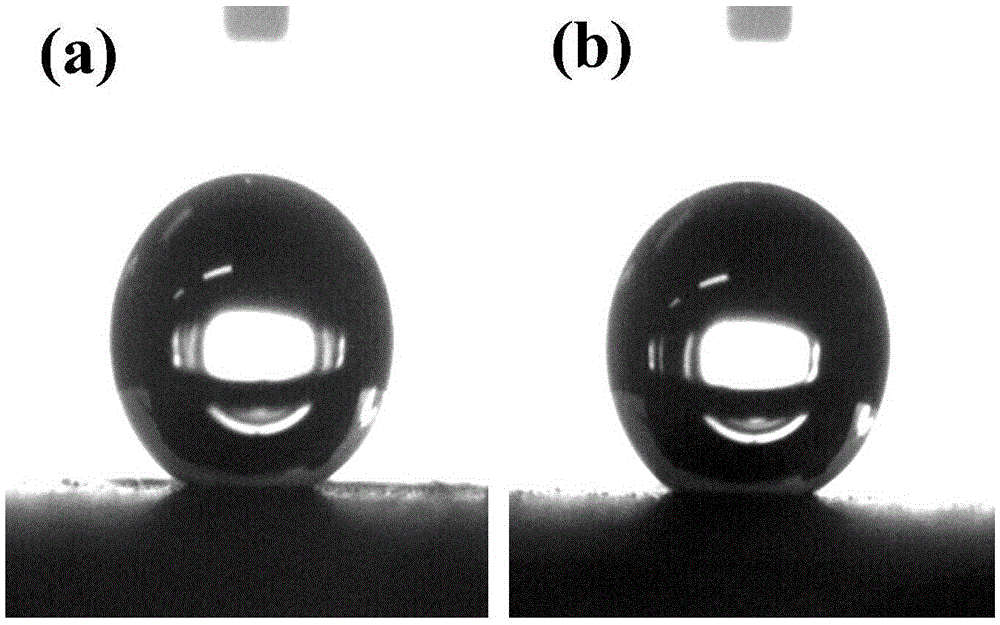

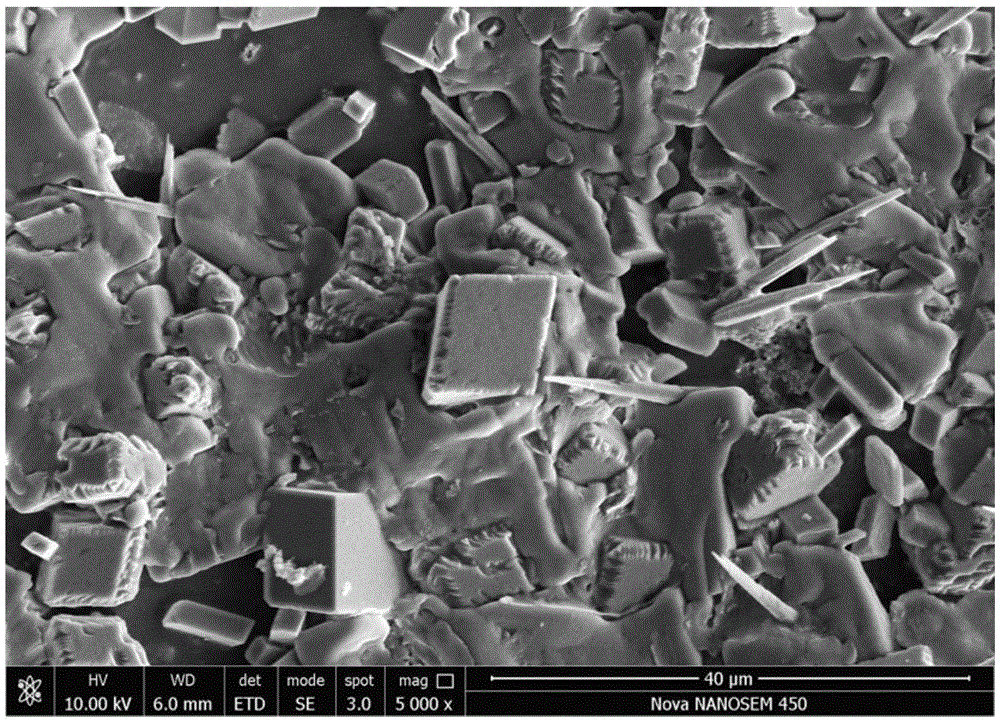

Preparing method of super-amphiphobic surface with scale preventing performance

A super-amphiphobic surface, anti-fouling technology, applied in the field of surface modification of metal materials, can solve the problems of easy corrosion and shorten the service life of steel, and achieve the effects of low production cost, reduced resistance and improved infusion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with specific embodiment, further illustrate the present invention. The following examples are only used to illustrate the present invention, and are not intended to limit the protection scope of the present invention. Improvements and adjustments made by skilled personnel according to the present invention in practical applications still belong to the protection scope of the present invention.

[0019] The preparation method of the superamphiphobic surface in this embodiment is completed by the following steps in turn:

[0020] (1) Select the X90 pipeline steel with a size of 20×50×3mm as the base sample, and the copper-zinc alloy (brass) with a size of 20×50×5mm as the counter electrode sample, and sand the processed X90 pipeline steel Grind smooth with the brass sample, and put the polished sample into acetone and absolute ethanol for 5 minutes for ultrasonic cleaning to remove grease and pollutants on the surface of the sample;

[0021] (2) Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com