Connecting-point-free metal sheet etching method and metal element group manufactured with same

A technology of thin metal plates and metal units, applied in the field of metal unit groups, to achieve the effects of reducing manpower and equipment costs, reducing processing procedures, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

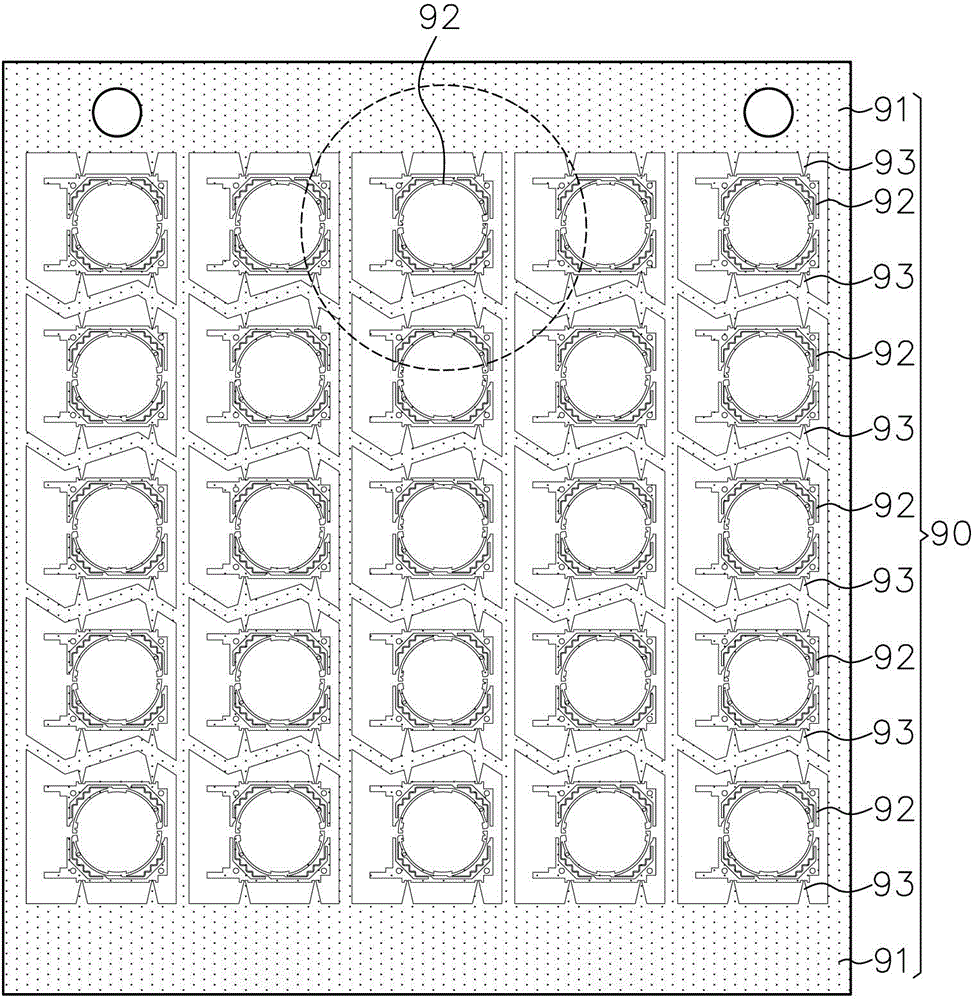

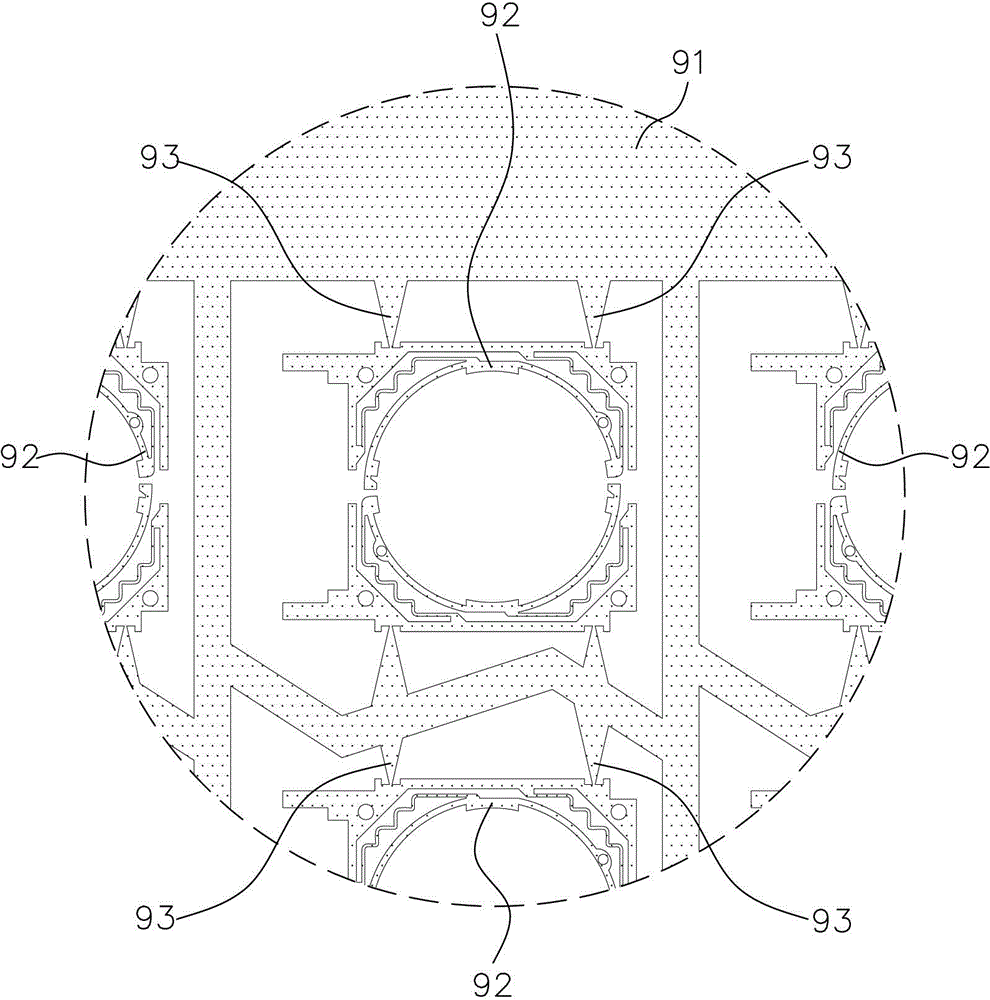

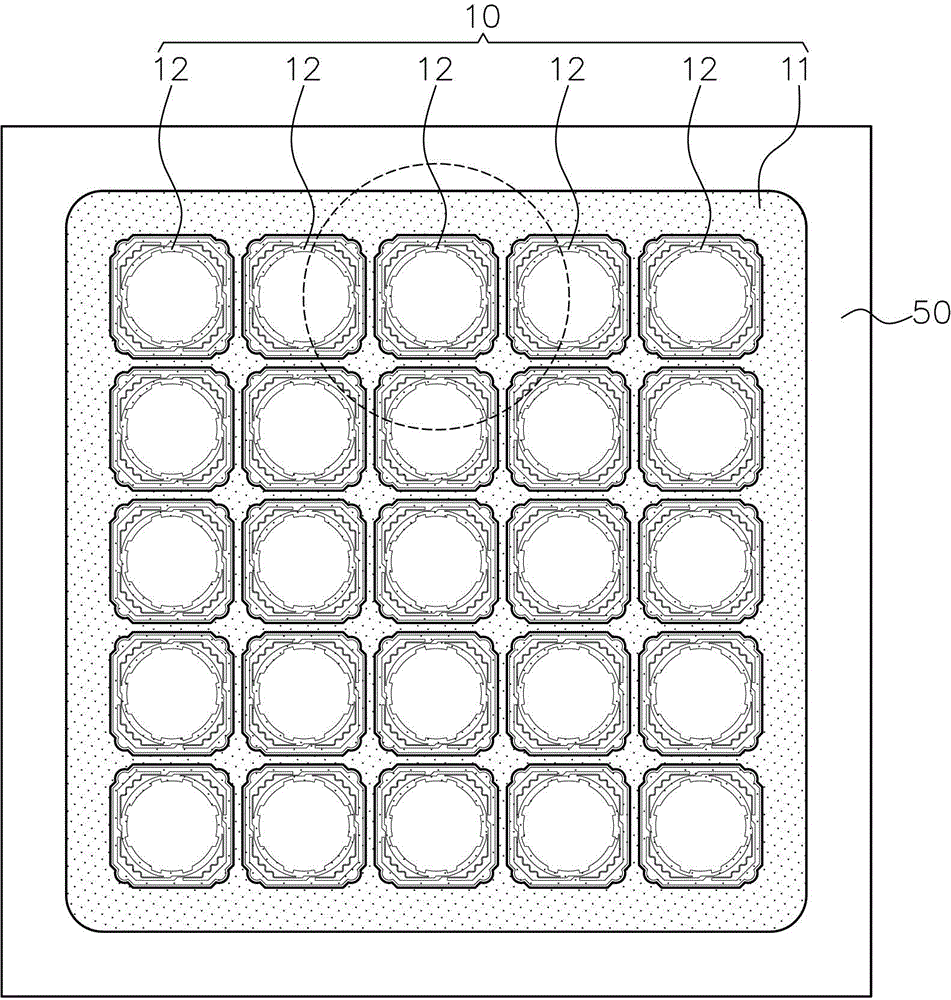

[0029] The embodiment of the present invention mainly uses ferric chloride (FeCl 3 ) or copper chloride (CuCl 2 ) chemical solution as an etchant to dissolve away the excess metal sheet that does not cover the dry film after exposure and development, please refer to Figure 5 and cooperate Figure 4A to Figure 4I As shown, the main steps can be divided into lamination step S1, exposure step S2, development step S3, etching step S4, film removal step S5, cleaning step S6, glue removal step S7, and inspection and packaging step S8. The steps are explained one by one:

[0030] First of all, before carrying out the compression molding step S1, a board cutting process will be carried out first, which means that the entire roll of large-area metal sheets (thickness is usually less than 0.1mm, if the product does not require the etching side, you can choose less than 0.2mm) Metal sheet), according to the planned optimal typesetting method, cut out the required size specifications,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com