Processing method for spectacle frame

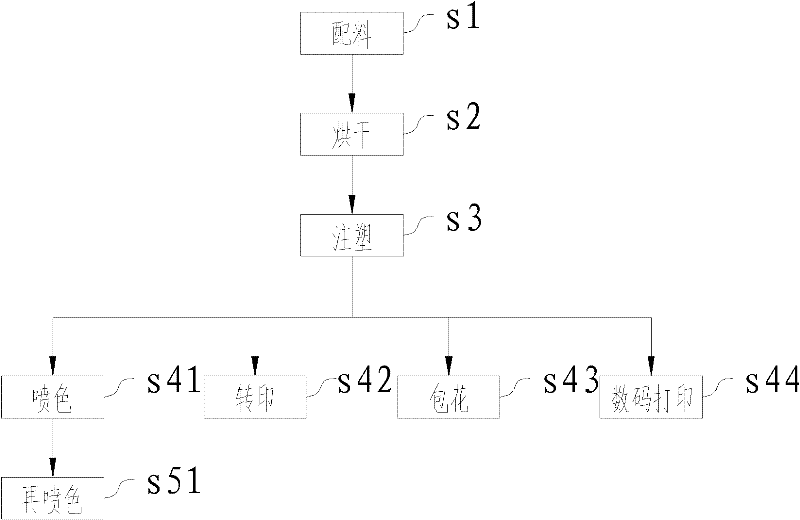

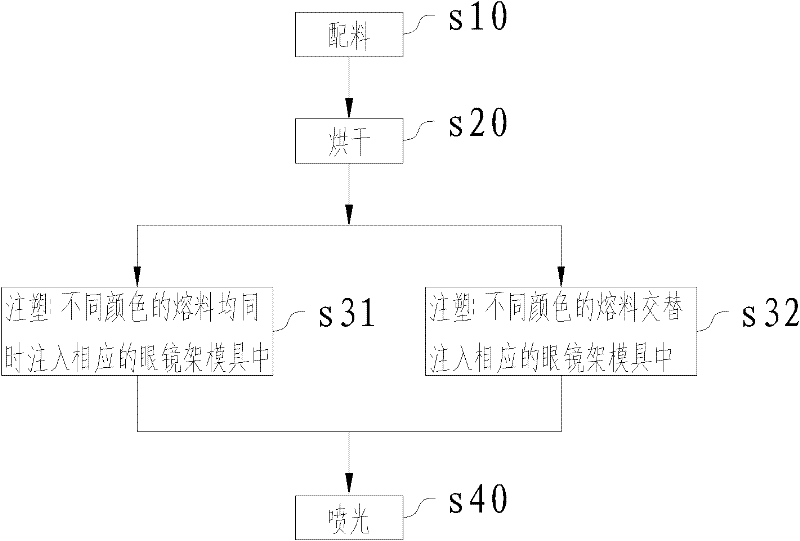

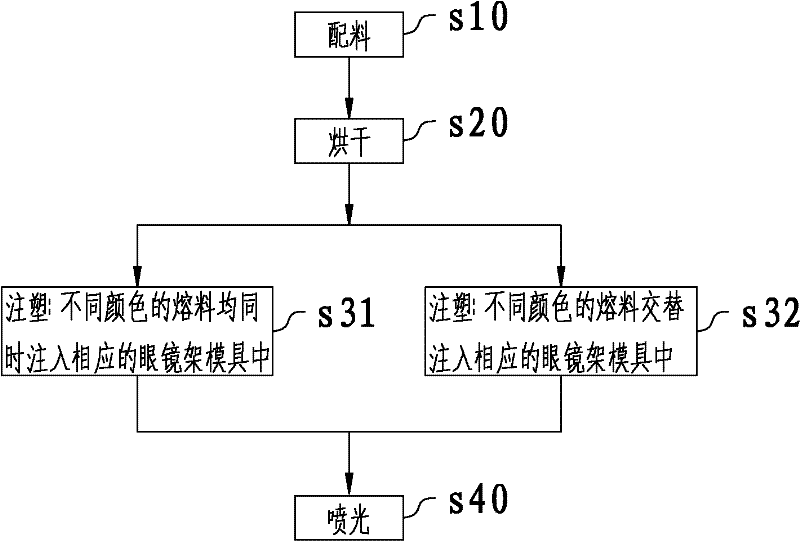

A processing method and technology for spectacle frames, which are applied in the directions of frames, household appliances, other household appliances, etc., can solve the problems affecting the processing efficiency of spectacle frames, the processing process is complicated, the processing procedures are cumbersome, etc., and the processing procedures are reduced, the processing process is simple, and the The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Glossary:

[0039] TR90: It has the advantages of light weight, good elasticity, and high polymer material with memory. It is the most popular ultra-light frame material in the world at present. It has super toughness, impact resistance and wear resistance, and low friction coefficient. Its specific molecular structure , good chemical resistance, not easy to deform in high temperature environment, can withstand high temperature of 350 degrees in a short time, not easy to melt and burn. No chemical residue release etc.

[0040] PC: Polycarbonate (Chinese name: polycarbonate) is an amorphous thermoplastic material. Because of its colorless and transparent properties, good heat resistance, strong impact resistance, and good processability, it is widely used in the production of optical discs, water bottles, bulletproof glass, and spectacle frames.

[0041] PVC: Polyvinyl chloride (Chinese name: polyvinyl chloride) is a well-loved, popular and widely used synthetic materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com