Composite biodiesel and preparation method thereof

A biodiesel and petrochemical diesel technology, applied in the field of fuel oil, can solve problems such as environmental pollution, and achieve the effects of solving environmental pollution, excellent stability and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

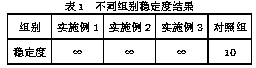

Examples

Embodiment 1

[0014] Embodiment 1: a, get 220 kilograms of biodiesel from Shandong Baiao Energy Technology Co., Ltd., 780 kilograms of No. 0 petrochemical diesel oil, 52 kilograms of isobutanol, 16 kilograms of diethylene glycol monooctyl ether, 2.2 kilograms of isooctyl nitrate, and 2.2 kilograms of isooctyl nitrate. Add 16 kg of alcohol polyoxyethylene ether (EH-9) into the LR-1000 high shear homogenizer, and stir at 2600-2800 rpm for 2-3 minutes at 40-45 °C;

[0015] b. Take 27 kg of castor oil polyoxyethylene ether (EL-20), 22 kg of sorbitol polyoxyethylene ether tetraoleate, 11 kg of diethylene glycol ethyl ether acetate, didecyl Add 13 kg of dimethylammonium chloride into the LR-1000 high-shear homogenizer, and stir at 2600-2800 rpm for 2-3 minutes at 50-55°C;

[0016] c. Add 200 kg of water to the mixture in step a, stir at 2600-2800 rpm for 2-3 minutes at 60-65°C; then add the mixture in step b, use HC- SH-2000 ultrasonic stirrer, under the condition of 70-75 ℃, stir for 30-50 minu...

Embodiment 2

[0017] Embodiment 2: a, get 200 kilograms of biodiesel from Shandong Baiao Energy Technology Co., Ltd., 750 kilograms of No. 0 petrochemical diesel oil, 50 kilograms of isobutanol, 15 kilograms of diethylene glycol monooctyl ether, 2 kilograms of isooctyl nitrate, Add 15 kg of alcohol polyoxyethylene ether (EH-9) into the LR-1000 high shear homogenizer, and stir at 2600-2800 rpm for 2-3 minutes at 40-45 °C;

[0018] b. Take 25 kg of castor oil polyoxyethylene ether (EL-20), 20 kg of sorbitol polyoxyethylene ether tetraoleate, 10 kg of diethylene glycol ethyl ether acetate, and didecyl dimethyl ammonium chloride 10 kg, add to LR-1000 high shear homogenizer, stir at 2600-2800 rpm for 2-3 minutes at 50-55°C;

[0019] c. Add 180 kg of water to the mixture in step a, stir at 2600-2800 rpm for 2-3 minutes at 60-65°C; then add the mixture in step b, use HC- SH-2000 ultrasonic stirrer, under the condition of 70-75 ℃, stir for 30-50 minutes, cool down and serve.

Embodiment 3

[0020] Embodiment 3: a, get 250 kilograms of biodiesel from Shandong Baiao Energy Technology Co., Ltd., 800 kilograms of No. 0 petrochemical diesel oil, 60 kilograms of isobutanol, 20 kilograms of diethylene glycol monooctyl ether, 2.5 kilograms of isooctyl nitrate, and 2.5 kilograms of isooctyl nitrate. Add 18kg of alcohol polyoxyethylene ether (EH-9) into the LR-1000 high shear homogenizer, and stir at 2600-2800 rpm for 2-3 minutes at 40-45°C;

[0021] b. Take 30 kg of castor oil polyoxyethylene ether (EL-20), 25 kg of sorbitol polyoxyethylene ether tetraoleate, 15 kg of diethylene glycol ethyl ether acetate, and didecyl dimethyl ammonium chloride 15 kg, put into LR-1000 high shear homogenizer, stir at 2600-2800 rpm for 2-3 minutes at 50-55°C;

[0022] c. Add 220 kg of water to the mixture in step a, stir at 2600-2800 rpm for 2-3 minutes at 60-65°C; then add the mixture in step b, and use HC- SH-2000 ultrasonic stirrer, under the condition of 70-75 ℃, stir for 30-50 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| stability | aaaaa | aaaaa |

| stability | aaaaa | aaaaa |

| stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com