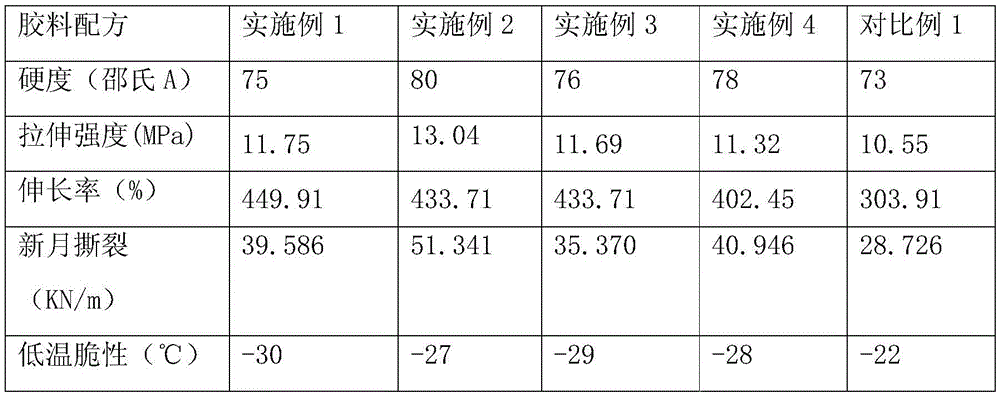

Formula and preparation method of high-elongation high-temperature-resistant fluororubber for rubber pipes

A technology of high elongation and fluororubber, which is applied in the field of fluororubber formulation and its preparation, can solve the problems of fluororubber being easy to crack, and achieve the effect of improving low temperature performance and excellent elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] A preparation method of fluororubber with high elongation and high temperature resistant rubber hose: comprising the following steps:

[0054] Step 1) Weigh the auxiliary agent in the fluororubber premix glue and the formula by weight and number of parts, and the auxiliary agent is magnesium oxide, oxide

[0055] Zinc, calcium hydroxide, carbon nanotubes, release agent, reinforcing agent, mixing the additives evenly; the high elongation high temperature resistant adhesive

[0056] The fluororubber formula of the pipe is made by mixing the raw materials in the following weight percentages:

[0057] Viton premixed rubber: 100 parts;

[0058] Magnesium oxide: 3-10 parts;

[0059] Zinc oxide: 3-10 parts;

[0060] Calcium hydroxide: 3-6 parts;

[0061] Carbon nanotubes: 1-5 parts;

[0062] Release agent: 0.5-2 parts;

[0063] Reinforcing agent: 10-20 parts;

[0064] Step 2) masticating the fluororubber premixed rubber in the internal mixer, then adding uniformly mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com