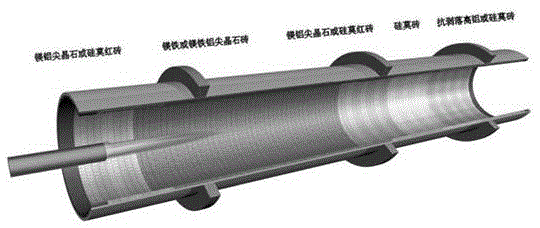

Preparation method of low-heat-conductivity magnesia-alumina spinel brick

A magnesia-aluminum spinel brick, low thermal conductivity technology, applied in chemical instruments and methods, manufacturing tools, ceramic molding machines, etc. The effect of loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] In this example, electric fusion and high-purity composite raw materials are used to produce low thermal conductivity magnesium-aluminum spinel bricks for the transition zone of cement kilns. Wherein the formula of each layer material is:

[0045] Refractory layer: sintered magnesia with a particle size of 5-0mm accounts for 45% of the total, and magnesium-aluminum spinel with a particle size of 4-0mm accounts for 10% of the total. Fused magnesia with a particle size of 3-0mm accounts for 40% of the total. The corundum particle size is 2-0mm, accounting for 5% of the total.

[0046] The specific ratio is as follows:

[0047] 5-0mm sintered magnesia 45%

[0048] 4-0mm magnesium aluminum spinel 10%

[0049] 3-0mm fused magnesia 40%

[0050] 2-0mm corundum 5%

[0051] The above-mentioned raw materials are weighed, mixed, and kneaded with a Na-based binder to make low thermal conductivity magnesium-aluminum spinel brick refractory layer raw materials.

[0052] Insula...

Embodiment 2

[0060] In this example, electric fusion and high-purity composite raw materials are used to produce low thermal conductivity magnesium-aluminum spinel bricks for the transition zone of cement kilns. Wherein the formula of each layer material is:

[0061] Refractory layer: sintered magnesia with a particle size of 5-0mm accounts for 60% of the total, and magnesium-aluminum spinel with a particle size of 4-0mm accounts for 10% of the total. Fused magnesia with a particle size of 3-0mm accounts for 25% of the total. The corundum particle size is 2-0mm, accounting for 5% of the total.

[0062] The specific ratio is as follows:

[0063] 5-0mm sintered magnesia 60%

[0064] 4-0mm magnesium aluminum spinel 10%

[0065] 3-0mm fused magnesia 25%

[0066] 2-0mm corundum 5%

[0067] The above-mentioned raw materials are weighed, mixed, and kneaded with a Na-based binder to make low thermal conductivity magnesium-aluminum spinel brick refractory layer raw materials.

[0068] Insula...

Embodiment 3

[0076] In this example, electric fusion and high-purity composite raw materials are used to produce low thermal conductivity magnesium-aluminum spinel bricks for the transition zone of cement kilns. Wherein the formula of each layer material is:

[0077] Refractory layer: sintered magnesia with a particle size of 5-0mm accounts for 68% of the total, and magnesium-aluminum spinel with a particle size of 4-0mm accounts for 10% of the total. Fused magnesia with a particle size of 3-0mm accounts for 19% of the total. The corundum particle size is 2-0mm, accounting for 3% of the total.

[0078] The specific ratio is as follows:

[0079] 5-0mm sintered magnesia 68%

[0080] 4-0mm magnesium aluminum spinel 10%

[0081] 3-0mm fused magnesia 19%

[0082] 2-0mm corundum 3%

[0083] The above-mentioned raw materials are weighed, mixed, and kneaded with a Na-based binder to make low thermal conductivity magnesium-aluminum spinel brick refractory layer raw materials.

[0084] Insula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com