Hot-dip galvanized steel sheet and manufacturing method thereof

A hot-dip galvanized steel sheet, hot-dip galvanized technology, applied in the hot-dip galvanized process, manufacturing tools, heat treatment furnaces, etc., can solve the problem of inability to manufacture hot-dip galvanized steel sheets with peeling resistance of the coating, and achieve the peeling resistance of the coating excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0090] Hereinafter, the present invention will be specifically described based on examples.

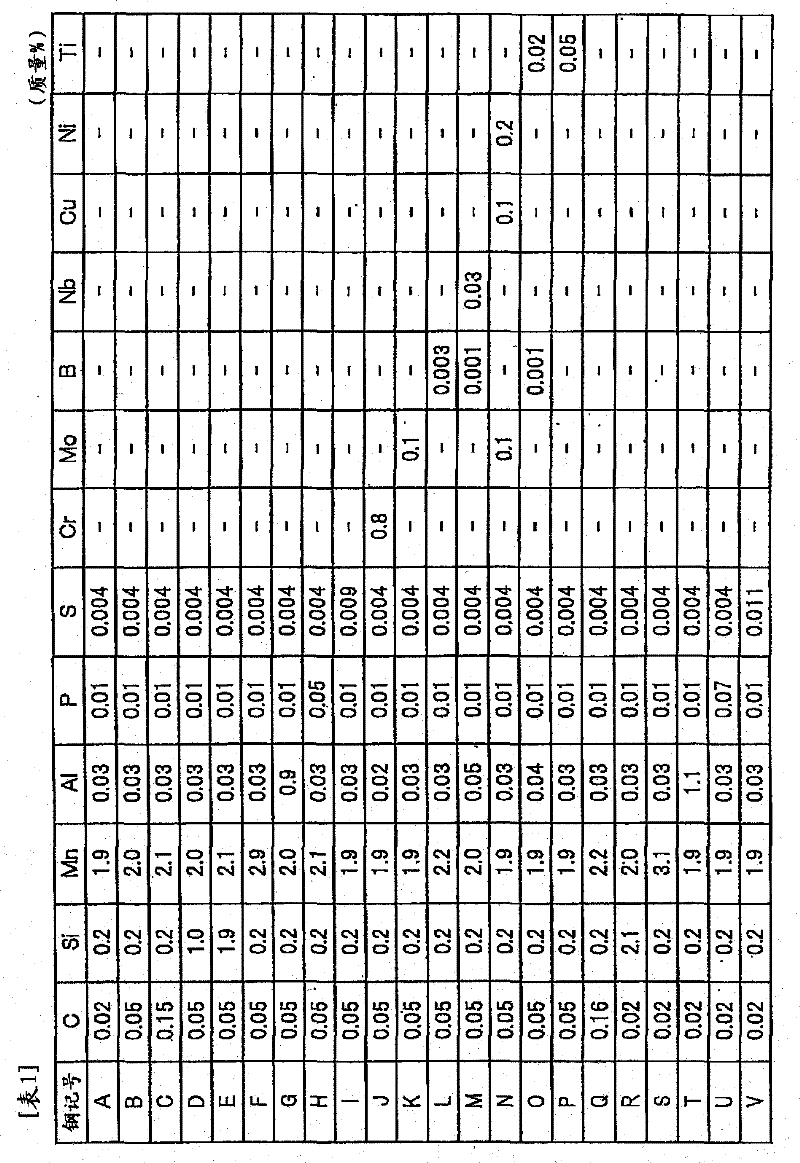

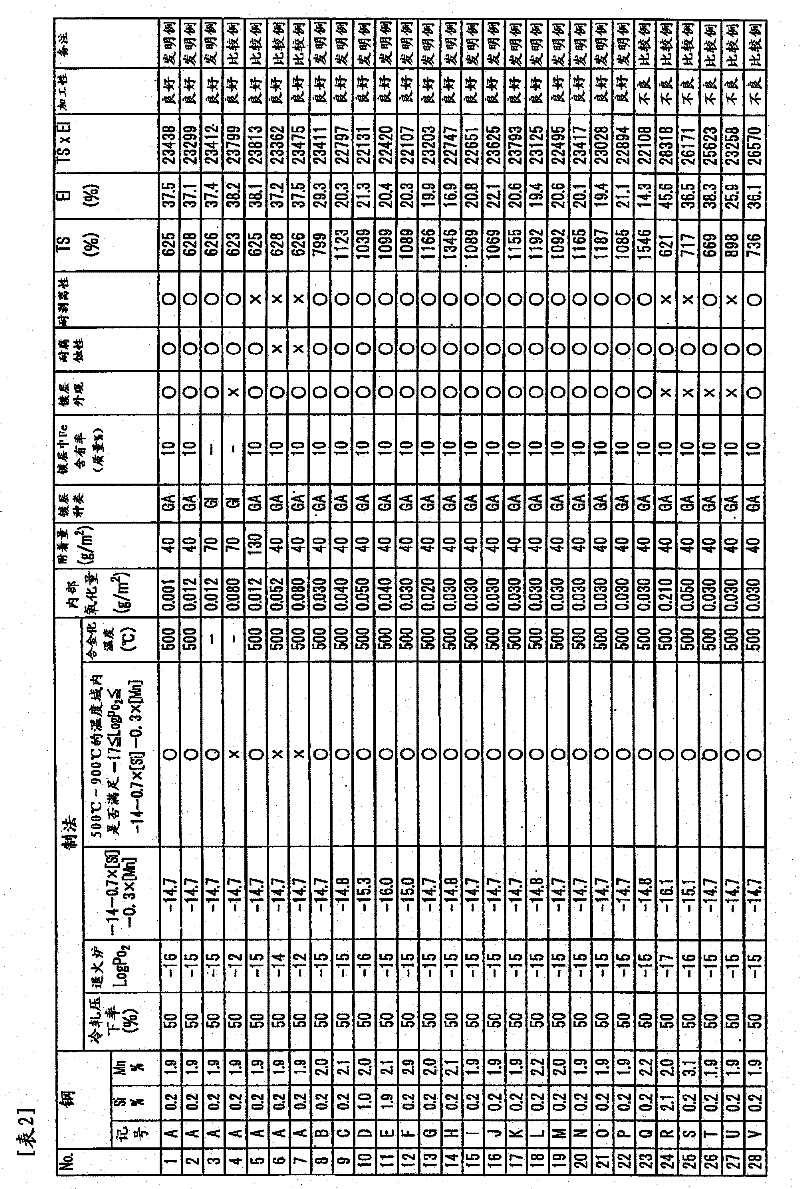

[0091] The hot-rolled steel sheets with the steel compositions shown in Table 1 were pickled to remove black scale, and then cold-rolled under the conditions shown in Table 2 to obtain cold-rolled steel sheets with a thickness of 1.0 mm.

[0092] Table 1

[0093]

[0094] The cold-rolled steel sheet obtained above was loaded into a CGL having a full-radiant tubular heating furnace as an annealing furnace. In CGL, Po of the annealing atmosphere is controlled in the manner shown in Table 2 2 The plate was passed through a furnace, heated to 850°C with a heating belt, annealed by soaking at 850°C with a soaking belt, and then hot-dip galvanized in a Zn bath containing Al at 460°C. It can be considered that the atmosphere in the annealing furnace, including the heating furnace and the soaking furnace, is basically uniform. In addition, the oxygen partial pressure and temperature wer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesion amount | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| adhesion amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com