Grid structural reinforced composite material sandwich structure

A composite material and sandwich structure technology, applied in building materials, truss structures, joists, etc., can solve the problems of low compression and shear resistance, weak bonding performance, and cannot be widely used, so as to improve the compression resistance and shear resistance, enhance the overall mechanical performance, and enhance the effect of anti-stripping ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

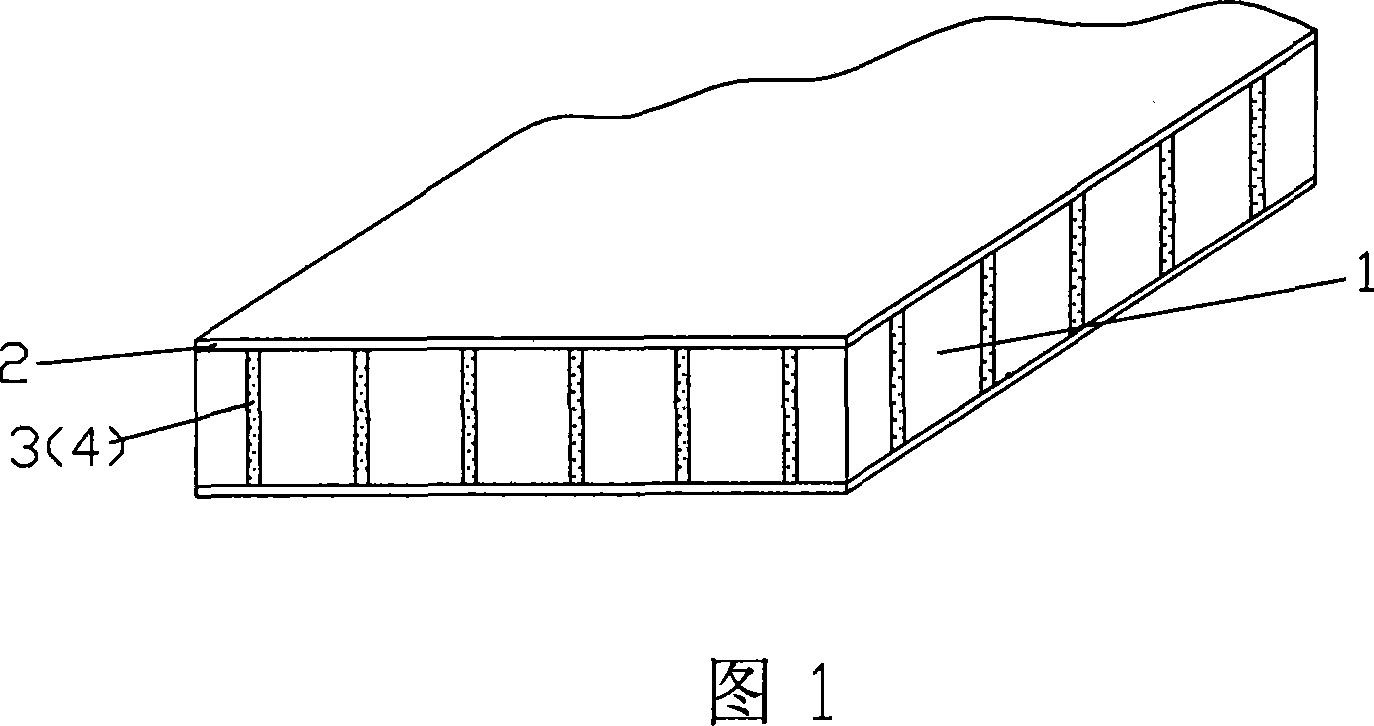

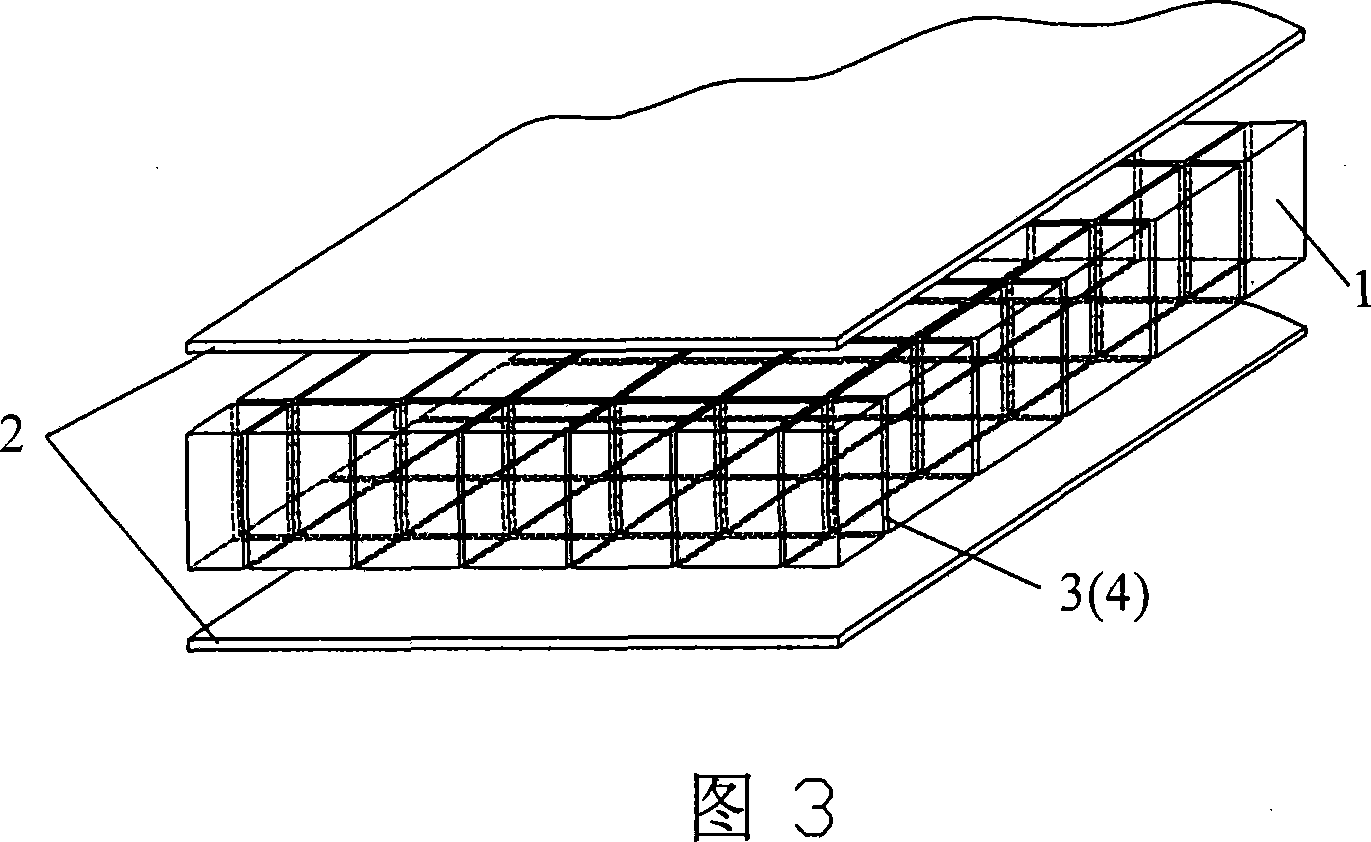

[0032] The lattice-reinforced composite material sandwich structure of the present invention comprises a core material 1 made of polyvinyl chloride foam, which is cut along the thickness direction of the core material 1, and the cut position is two-way orthogonal and vertically arranged, wherein it is filled with The resin web 3 is formed after the epoxy resin, and two layers of biaxial carbon fiber cloth are laid on the upper and lower surfaces of the core material 1, and the fiber panel 2 can be formed by curing with the epoxy resin.

Embodiment 2

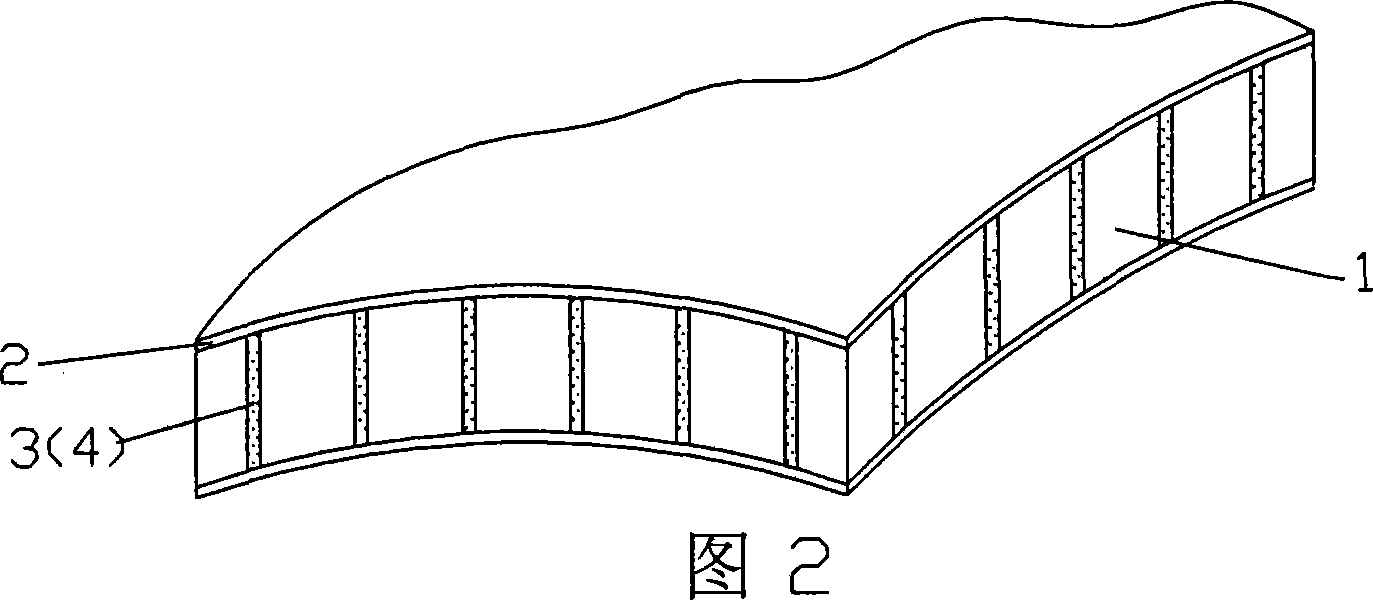

[0034] The lattice-reinforced composite material sandwich structure of the present invention comprises a core material 1 made of paulownia wood, which is cut along the thickness direction of the core material 1, and the cutting position is two-way orthogonal and obliquely arranged, and is filled with glass fiber cloth , it is cured with vinyl resin to form a resin web 4, three layers of four-axis glass fiber cloth layers are laid on the upper surface of the core material 1, and three layers of four-axis aramid fiber cloth layers are laid on the lower surface of the core material 1, They are cured with vinyl resin to form the fiber panel 2 .

[0035] As described in Embodiment 1, when the core material 1 is cut, the number, size and arrangement of the cut positions can be flexibly controlled according to the force requirements.

Embodiment 3

[0037] The lattice-reinforced composite material sandwich structure of the present invention comprises a core material 1 made of polyurethane foam, cut along the thickness direction of the core material 1, and the cut position is unidirectional and obliquely arranged, and filled with carbon fiber cloth. After the phenolic resin is cured, the resin web 4 is formed. Three layers of four-axial glass fiber cloth are laid on the upper surface of the core material 1, and five layers of four-axial glass fiber cloth are laid on the lower surface. They are cured with the phenolic resin to form a composite material. Web 4.

[0038] As described in Embodiments 1 and 2, the thickness of the fiber panels 2 arranged on the upper and lower surfaces of the core material 1 may be consistent or not.

[0039] The preparation method of the above-mentioned lattice-reinforced composite sandwich structure is as follows:

[0040] a. Cut in the thickness direction of the core material 1 of foam (incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com