Anti-reflection super-hydrophobic self-cleaning SiO2 nano coating

A technology of anti-reflection and anti-reflection, nano-coating, applied in the direction of coating, etc., can solve the problem of poor wear resistance and heat resistance of glass products, high energy consumption, self-cleaning and anti-fog effects and unsatisfactory durability, etc. problem, to achieve the effect of good superhydrophobic self-cleaning performance, simple equipment and excellent superhydrophobic self-cleaning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Small and non-porous SiO with a particle size of 10 to 25 nm 2 Preparation of nanoparticles:

[0042] (1) Add 100 milliliters of ethanol and 4 to 6 milliliters of ammonia water into a 250 milliliter round bottom flask, and stir in a water bath at 40 to 60 degrees Celsius;

[0043](2) After the temperature is constant, add 2 to 5 milliliters of tetraethoxysilane into the mixed solution, and continue to stir for 12 hours to obtain the small and non-porous SiO 2 particle.

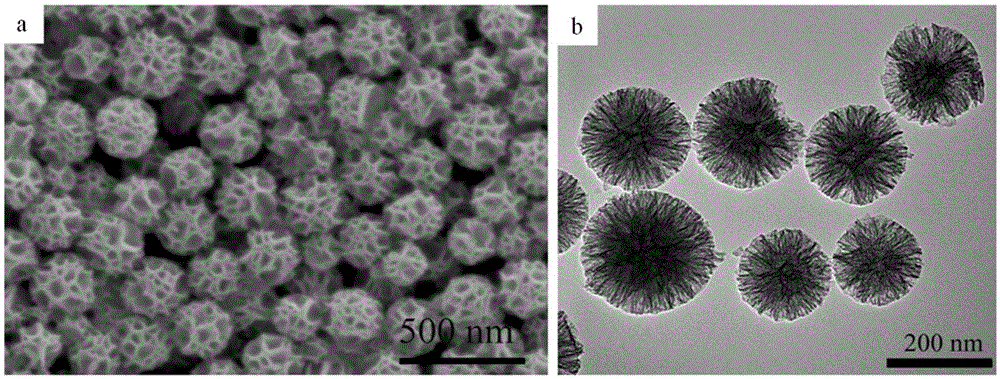

[0044] Take a small amount of sample and disperse it in ethanol, spot the sample on the copper grid of the scanning table and the transmission electron microscope, then observe with the scanning electron microscope and the transmission electron microscope, as figure 1 a, 1b shown. figure 1 a and figure 1 b are small-sized and non-porous SiO, respectively 2 Scanning electron micrographs and transmission electron micrographs of nanoparticles. figure 1 a shows that the obtained small-sized and non-po...

Embodiment 2

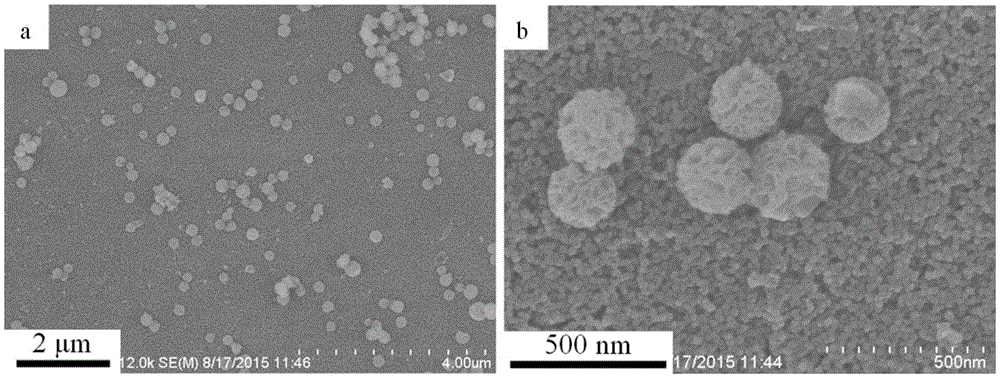

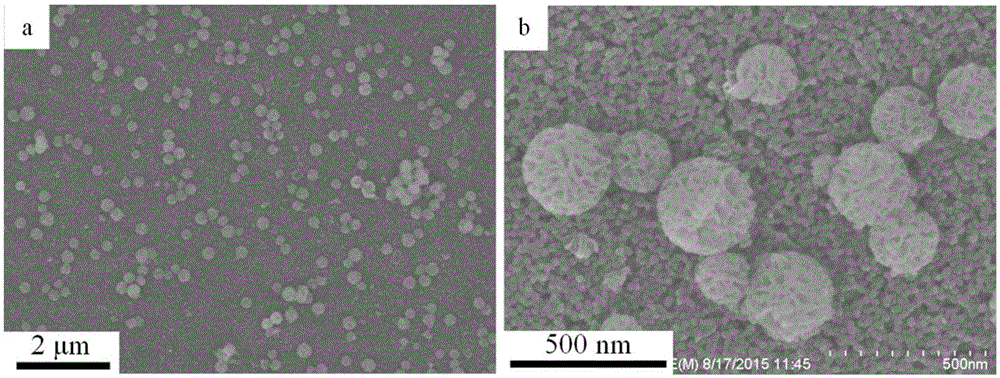

[0047] SiO with a dendritic hierarchical pore structure 2 Particle preparation:

[0048] (1) At 20 degrees Celsius, dissolve 0.5 gram of cetyltrimethylammonium bromide in 70 milliliters of distilled water, then add 15 milliliters of ether, 5 milliliters of ethanol, and 0.8 milliliters of 30% ammonia solution , forming an emulsion system;

[0049] (2) After the emulsion obtained in step (1) was stirred vigorously for 30 minutes at 20 degrees Celsius, a mixture of 2.5 milliliters of tetraethoxysilane and 0.1 milliliters of aminopropyltriethoxysilane was quickly added to the emulsion, The final mixture was vigorously stirred and reacted at 20 degrees Celsius for 4 hours, and then 1 ml of 37% hydrochloric acid solution was added to terminate the reaction;

[0050] (3) centrifuging the white precipitate obtained by step (2) reaction, washing, and dispersing in the ethanol solution;

[0051] (4) Ultrasonic dispersion of the product of step (3) dispersed into ethanol solution;

...

Embodiment 3

[0059] The bottom layer is made of small size and non-porous SiO 2 Anti-reflection and anti-reflection coating constructed of nanoparticles: Its preparation is to use the small-sized and non-porous SiO with a mass percentage of 0.1 to 6% and a particle size of 10 to 25 nm obtained in Example 1. 2 The ethanol suspension of nanoparticle is used as raw material, and its preparation method comprises the following steps:

[0060] (1) ultrasonically washing the glass sheet in ultrapure water for 5 to 30 minutes and treating it with oxygen plasma for 1 to 20 minutes;

[0061] (2) Put the glass sheet cleaned in step (1) on a small-sized and non-porous SiO 2 Pull the nanoparticle ethanol suspension 1, 2, 3, 4, 5 times respectively, the pulling speed is 20-200 mm / min, soak in the suspension for 5-50 seconds, and stand in the room after pulling out each time 5-60 seconds.

[0062] Figure 4 It shows that the blank glass and Example 3 are deposited on the glass sheet with 1, 2, 3, 4, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com