Metal-plated stainless steel material, and production method for metal-plated stainless steel material

A manufacturing method, stainless steel technology, applied in the direction of metal material coating process, superimposed layer plating, liquid chemical plating, etc., can solve the problems of metal plating layer peeling, etc., achieve excellent corrosion resistance and electrical conductivity, and improve coverage High efficiency and tightness, cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0102] First, a stainless steel material (SUS316L) for forming the stainless steel sheet 10 is prepared. Next, the prepared stainless steel material was immersed in a sulfuric acid aqueous solution with a sulfuric acid concentration of 25% by volume at a temperature of 70° C. and an immersion time of 5 seconds to obtain a stainless steel plate 10 with a passivation film 11 formed on the surface.

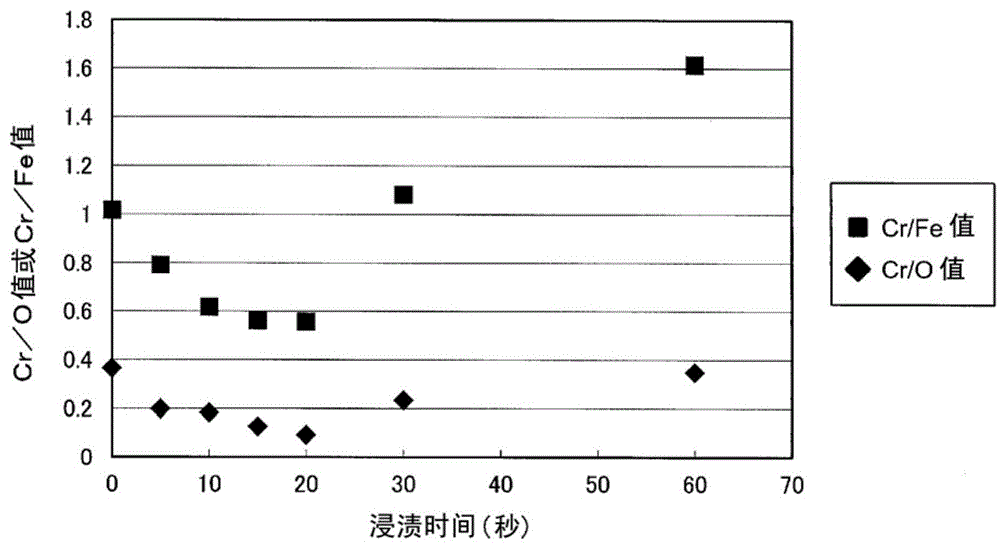

[0103] Then for this stainless steel plate 10 that is formed with passivation film 11, according to above-mentioned method, carry out the mensuration of Cr / O value and Cr / Fe value and the mensuration of surface roughness, the result is as table 1 and image 3 , 4 shown. In addition, Table 1 also shows the results obtained by applying the above-mentioned formula (1) to the concentration x [volume %], temperature y [°C], and immersion time z [seconds] when stainless steel materials are immersed in sulfuric acid aqueous solution.

[0104] It should be noted, image 3 This is a graph ...

Embodiment 2~8

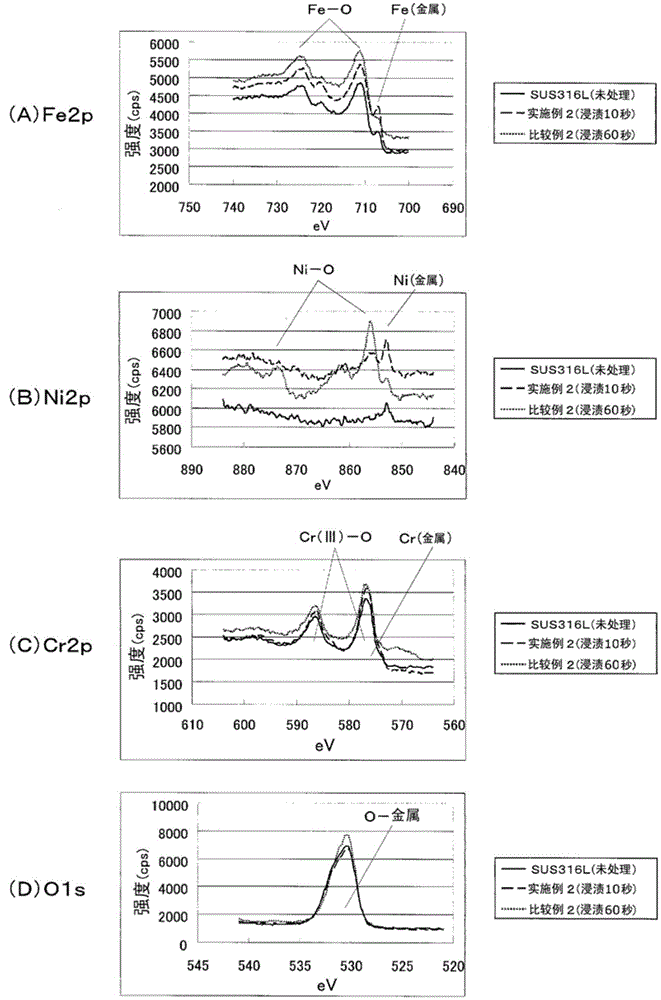

[0107] The concentration, temperature and immersion time when the stainless steel material is immersed in the sulfuric acid aqueous solution are as shown in Table 1, except that the stainless steel plate 10 is produced in the same manner as in Example 1, and the Cr / O value and Cr / Fe value are determined according to the above method. Determination, XRD analysis, XPS measurement, surface roughness measurement, section observation, electron beam diffraction pattern measurement. The results are shown in Table 1, Figure 2-7 shown.

[0108] It should be noted, figure 2 The results obtained by measuring the peaks of Fe2p, Ni2p, Cr2p, and O1s on the surface of the passivation film 11 formed on the stainless steel sheet 10 by XPS measurement are shown. here, figure 2 (A) shows the results obtained by measuring the peak of Fe2p, figure 2 (B) shows the result obtained by measuring the peak of Ni2p, figure 2 (C) represents the result obtained by measuring the peak of Cr2p, fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coverage | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com