Method of modifying polymers

A polymer and modification technology, applied in chemical instruments and methods, artificial filaments made of cellulose derivatives, plant peptides, etc., can solve problems such as modification difficulties and achieve the effect of easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

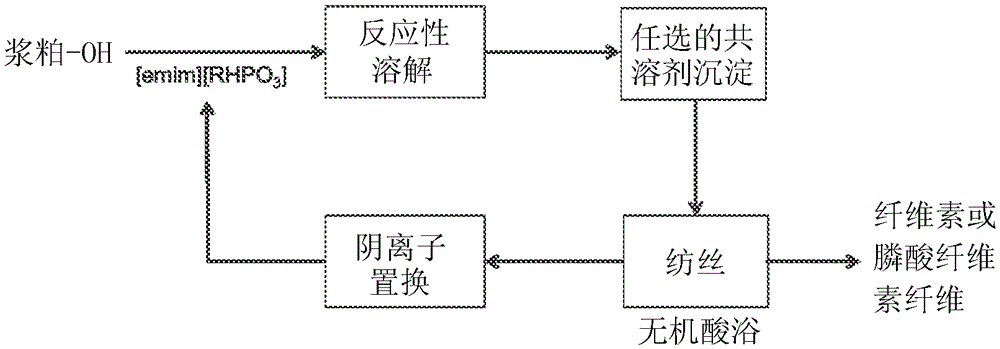

Method used

Image

Examples

Embodiment 1

[0089] 1-Ethyl-3-methylimidazolium methylphosphonate (1-Ethyl-3-methylimidazoliummethylphosphonate) ([emim][MeHPO 3 ])synthesis

[0090] 1-Ethylimidazole (96.1 g, 1.00 mol) was added dropwise (within 1 hour) to pure dimethyl phosphite (110.0 g, 1.00 mol) at 85°C. The reaction was allowed to stir for an additional 18 hours at 80°C. The mixture was rotary evaporated under high vacuum at 65 °C for 18 hours to yield a clear pale yellow oil (206.0 g).

[0091] Reactants and reaction steps are also shown in figure 1 middle.

Embodiment 2

[0093] Methyltrioctylphosphoniummethylphosphonate (methyltrioctylphosphoniummethylphosphonate) ([P 8881 ][MeHPO 3 ]synthesis

[0094] Trioctylphosphine (370 g, 1.00 mol) was added dropwise (within 1 hour) to pure dimethyl phosphite (110.0 g, 1.00 mol) at 85°C under argon. The reaction was allowed to stir for an additional 18 hours at 80°C. The mixture was rotary evaporated under high vacuum at 65 °C for 18 hours to yield a clear pale yellow oil (480 g).

Embodiment 3

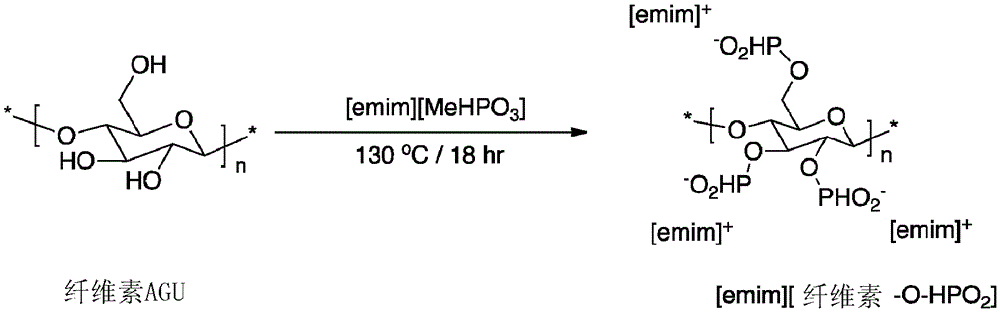

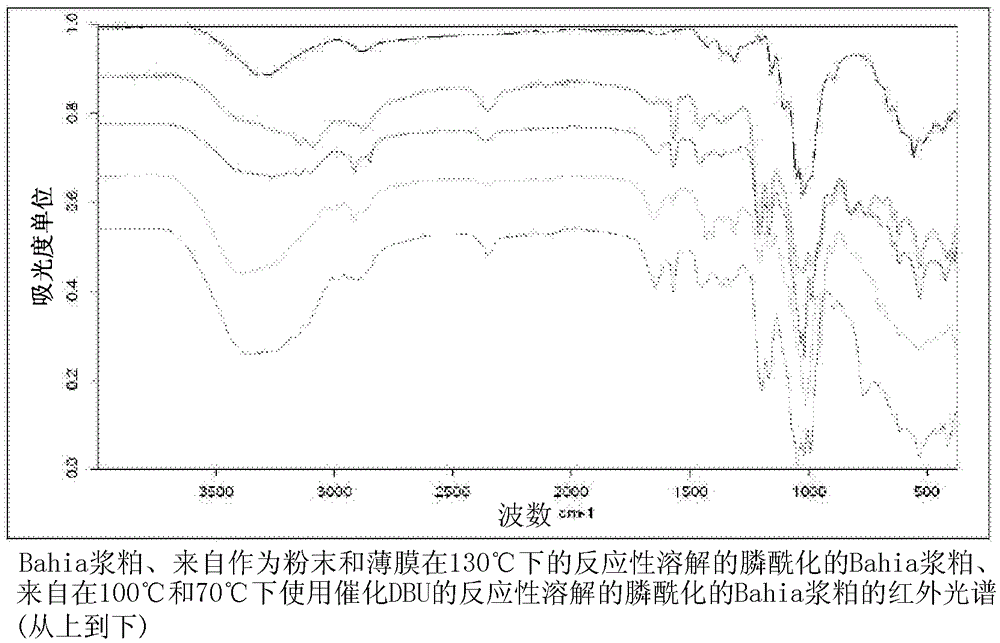

[0096] with [emim][MeHPO 3 ] Modification of prehydrolyzed kraft (PHK) pulp at 130 °C

[0097] [emim][MeHPO 3 ] 95 g was added to a flask containing PHK (5 g). The mixture was stirred at 130° C. for 18 hours under an argon atmosphere. The reaction mixture was diluted with an equal volume of methanol and filtered through a G3 sintered funnel. The crude product was precipitated by slow addition of acetone (3 volumes). The precipitate was washed with additional acetone:methanol (95:5). The material was reprecipitated using the same methanol acetone precipitation and volume. The resulting sample was then dried in a vacuum oven to yield a white powder (9.5 g). The resulting product is water soluble.

[0098] Reactants and reaction steps are also shown in figure 2 middle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com