Weather-resistant film for solar photovoltaic cell

A solar photovoltaic panel and weather-resistant technology, applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of difficult import, easy aging, layer-to-layer peeling, etc., and achieve easy popularization and application, low manufacturing cost, and enhanced structure The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the embodiments, so that those skilled in the art can implement it with reference to the description.

[0024] This case proposes an embodiment of a weather-resistant back film for solar photovoltaic panels, which is sequentially provided with a weather-resistant layer, an adhesive layer and a corrosion-resistant layer from top to bottom;

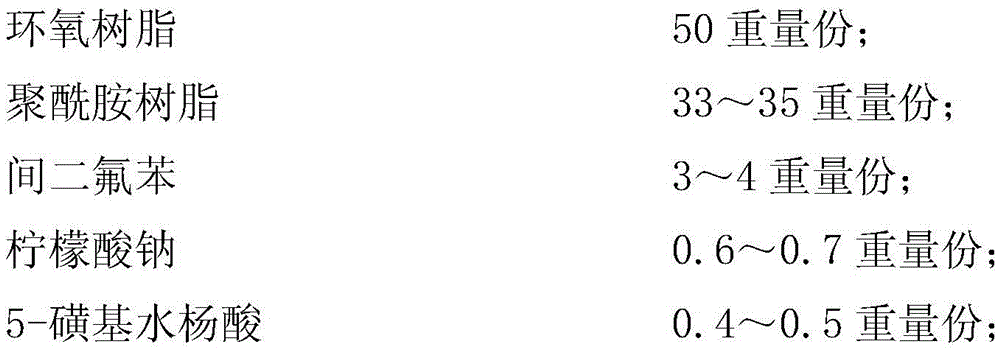

[0025] Wherein, the weather-resistant layer includes the following materials by weight:

[0026]

[0027] The adhesive layer comprises the following materials by weight:

[0028] 50 parts by weight of polymethyl methacrylate;

[0029] Propylene-octyl methacrylate copolymer 20~22 parts by weight;

[0030] 2-3 parts by weight of ammonium phosphate.

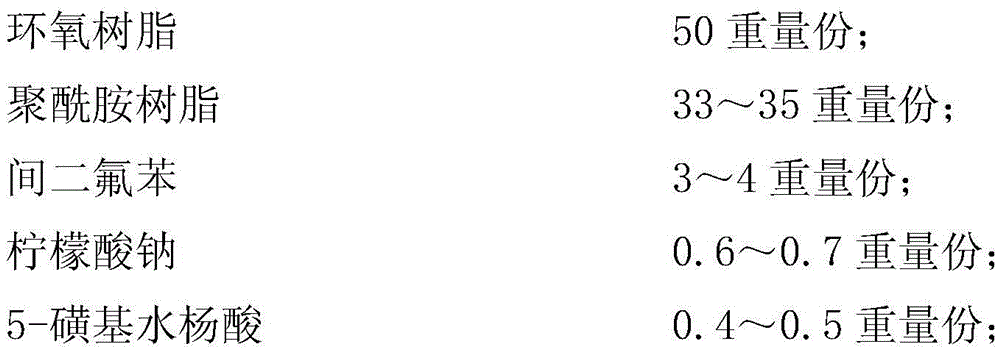

[0031] In the above embodiments, the anti-corrosion layer preferably includes the following materials in parts by weight:

[0032]

[0033] In the above embodiments, in the weather-resistant layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com