A low-thermal-conduction class A non-combustible sandwich insulation board and its manufacturing method

A technology of low thermal conductivity and thermal insulation boards, applied in thermal insulation, insulation improvement, building components, etc., can solve the problems of long production cycle, poor fire performance, and many safety hazards, and achieve improved waterproof and weather resistance, high impact strength, The effect of high bonding strength between layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The modified polyurethane rigid foam is prepared from the following raw material ratios by weight: 55 parts of polyol materials, 5 parts of ethylenediamine polyoxypropylene tetraol, 4 parts of melamine, 0.2 parts of triethylenediamine solution, 15 parts of ethyl chloride, 1 part of polyalkoxy ether copolymer, 5 parts of trichloroethyl phosphate, 44 parts of isocyanate;

Embodiment 2

[0040] The modified polyurethane rigid foam is prepared from the following raw material proportions by weight: 75 parts of polyol material, 30 parts of ethylenediamine polyoxypropylene tetraol, 6 parts of melamine, 0.5 part of triethylenediamine solution, 20 parts of ethyl chloride, 2 parts of polyalkoxy ether copolymer, 12 parts of trichloroethyl phosphate, 66 parts of isocyanate;

Embodiment 3

[0042] The modified polyurethane rigid foam is prepared from the following raw material proportions by weight: 95 parts of polyol material, 40 parts of ethylenediamine polyoxypropylene tetraol, 8 parts of melamine, 0.8 part of triethylenediamine solution, 25 parts of ethyl chloride, 3 parts of polyalkoxy ether copolymer, 20 parts of trichloroethyl phosphate, 88 parts of isocyanate;

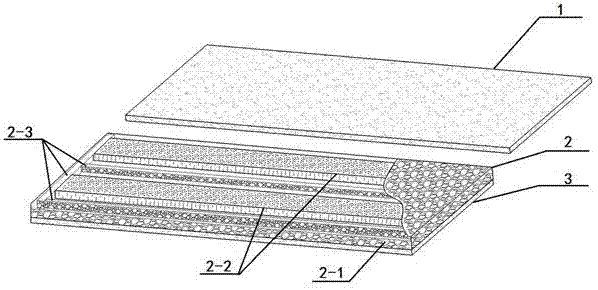

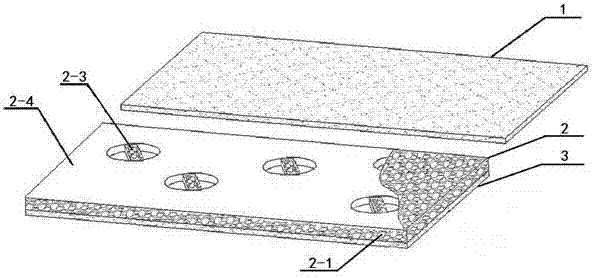

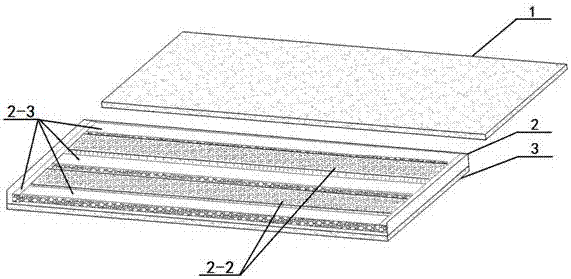

[0043] The low thermal conductivity class A non-combustible sandwich insulation board of the present invention is divided into three types of boards: A, B, and C, among which:

[0044] (1) The production method of A board is to carry out according to the following steps:

[0045] Step 1, place the upper board 1 and the lower board 3 respectively on the upper and lower crawlers of the conveying device of the insulation board production equipment, the upper and lower crawlers move synchronously, and the lower board 3 is transported to the gluing station by the lower crawler. The glue applicator spr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com