Paste composition for PVC (Polyvinyl Chloride) foaming wallpaper

A technology of composition and paste, which is applied in special paper, paper, papermaking, etc., can solve the problems of inability to eliminate electromagnetic pollution, inability to absorb electromagnetic waves, etc., and achieve mold suppression, performance improvement, and good compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

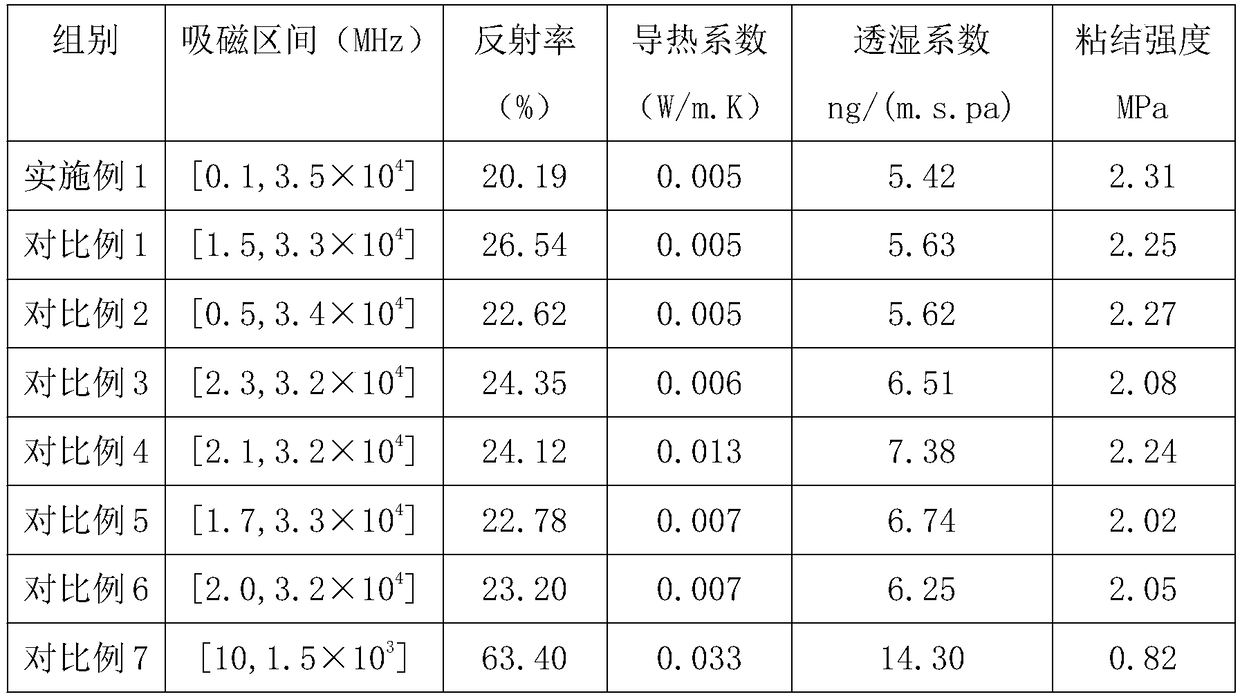

Examples

Embodiment 1

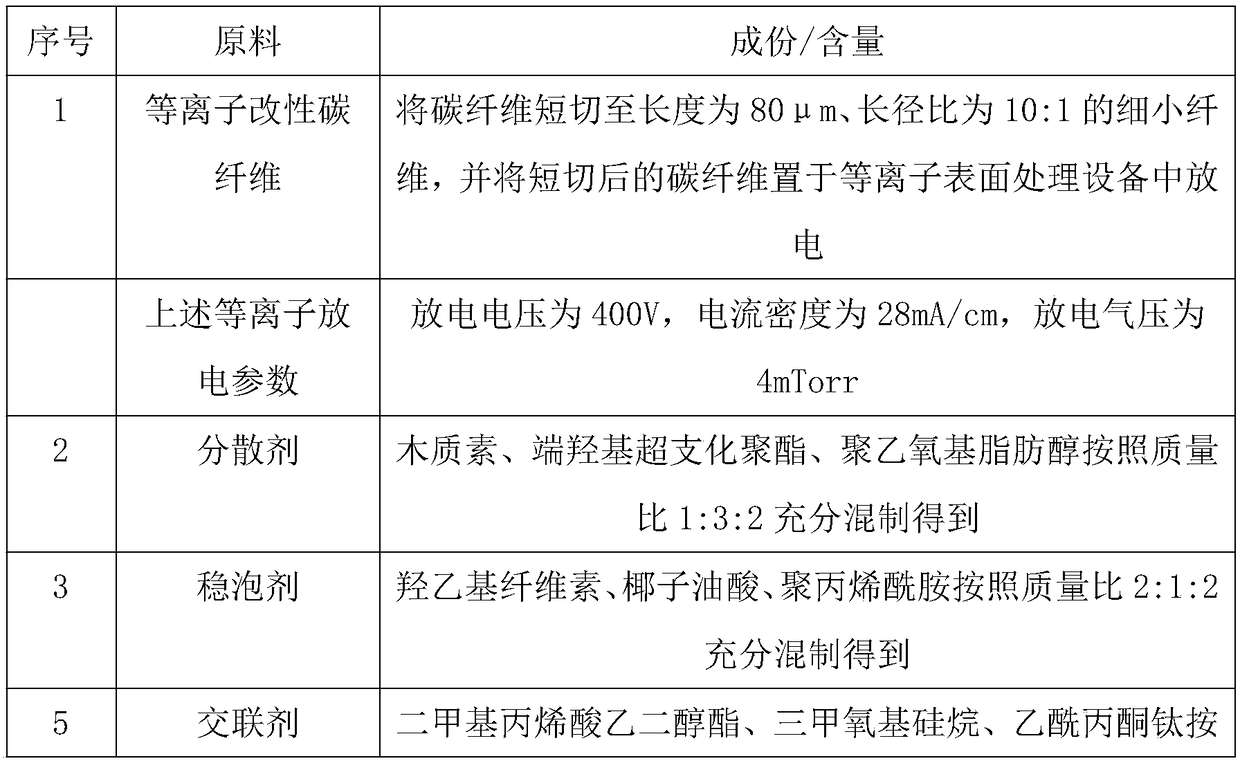

[0050] This embodiment relates to a paste composition for PVC foam wallpaper and a preparation method thereof. The following raw materials are weighed in parts by weight for preparation:

[0051] 70 parts of polyvinyl chloride paste resin SG-5;

[0052] 18 parts of terpene resin;

[0053] 3 parts of plasma modified boron fiber;

[0054] 2 parts of niobium yttrium ore powder;

[0055] 3 parts porous basalt;

[0056] 2 parts of chlorite;

[0057] 1 part of expandable graphite with an expansion rate of 300ml / g;

[0058] 3 parts of Wudalianchi volcanic ash;

[0059] 1 part of ITO powder;

[0060] 0.75 parts of diacetone acrylamide;

[0061] 0.6 part of polyvinyl acetate;

[0062] 2 parts of polyvinyl alcohol;

[0063] 1 part of dispersant;

[0064] 1.6 parts of ADC foaming agent;

[0065] 0.3 part of foam stabilizer;

[0066] 1.4 parts of crosslinking agent;

[0067] 1.5 parts of coupling agent.

[0068] The preparation of the above-mentioned part of the raw materials ...

Embodiment 2

[0099] This embodiment relates to a paste composition for PVC foam wallpaper and a preparation method thereof. The following raw materials are weighed in parts by weight for preparation:

[0100] 75 parts of polyvinyl chloride paste resin SG-5;

[0101] 24 parts of terpene resin;

[0102] 3.5 parts of plasma modified boron fiber;

[0103] 2.5 parts of niobium yttrium ore powder;

[0104] 4 parts porous basalt;

[0105] 2.5 parts of chlorite;

[0106] 1.25 parts of expandable graphite with expansion ratio of 300ml / g;

[0107] 4 parts of Wudalianchi volcanic ash;

[0108] 1.5 parts of ITO powder;

[0109] 0.95 parts of diacetone acrylamide;

[0110] 0.8 part of polyvinyl acetate;

[0111] 2.5 parts of polyvinyl alcohol;

[0112] 1.1 parts of dispersant;

[0113] 1.9 parts of ADC foaming agent;

[0114] 0.4 parts of foam stabilizer;

[0115] 1.7 parts of crosslinking agent;

[0116] 1.8 parts of coupling agent.

[0117] The preparation of the above-mentioned part ra...

Embodiment 3

[0132] This embodiment relates to a paste composition for PVC foam wallpaper and a preparation method thereof. The following raw materials are weighed in parts by weight for preparation:

[0133] 80 parts of polyvinyl chloride paste resin SG-5;

[0134] 26 parts of terpene resin;

[0135] 4 parts of plasma modified boron fiber;

[0136] 3 parts of niobium yttrium ore powder;

[0137] Porous basalt 5 parts;

[0138] 3 parts of chlorite;

[0139] 1.5 parts of expandable graphite with an expansion rate of 300ml / g;

[0140] Wudalianchi volcanic ash 5 parts;

[0141] 2 parts of ITO powder;

[0142] 1.15 parts of diacetone acrylamide;

[0143] 1 part polyvinyl acetate;

[0144] 3 parts of polyvinyl alcohol;

[0145] 1.2 parts of dispersant;

[0146] 2.2 parts of ADC foaming agent;

[0147] 0.5 part of foam stabilizer;

[0148] 2 parts of crosslinking agent;

[0149] 2.1 parts of coupling agent.

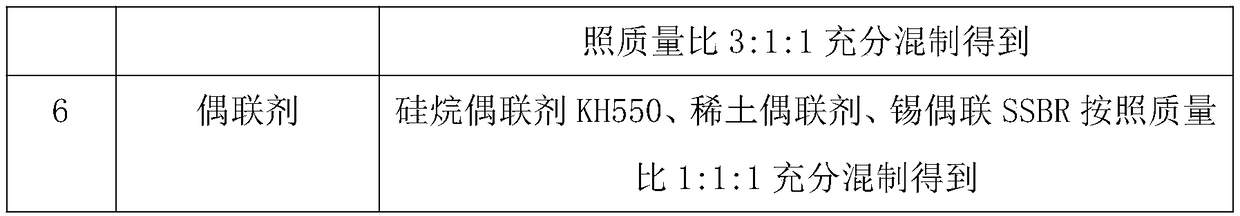

[0150] The preparation of above-mentioned part raw material is as shown in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Expansion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com