Anti-pilling air layer fabric with wool surface

An air layer and anti-pilling technology, which is applied in wear-resistant fibers, textiles, papermaking, and fiber treatment, can solve the problems of reducing the friction coefficient of fiber surfaces, complicating the composition of anti-pilling additives, and unfavorable large-scale production. It achieves the effect of increasing heat preservation effect, simple and easy drying operation, and reducing directional friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

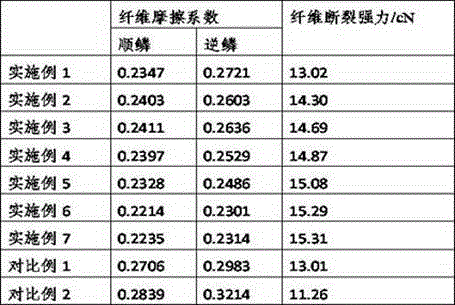

Examples

Embodiment 1

[0023] The anti-pilling wool face air layer fabric of embodiment 1, the air layer fabric is formed by sewing the wool fabric and the air layer auxiliary material, and the wool fabric is subjected to anti-pilling finishing, and the above-mentioned anti-pilling finishing includes the following steps:

[0024] S1: Configure the first finishing solution and the second finishing solution. The main components of the first finishing solution are keratin powder, organic acid and water. The weight percentage of keratin powder in the first finishing solution is 1%; The main components are ethylenediamine-modified polylactic acid, ethyl lactate and polycarbodiimide, the weight percentage of ethylenediamine-modified polylactic acid in the second finishing liquid is 0.2%, polycarbodiimide and ethylenediimide The weight ratio of amine-modified polylactic acid is 0.03:1;

[0025] S2: immerse the wool fabric in the first finishing solution, soak it at room temperature for 1 hour, take out the...

Embodiment 2

[0030] The difference between embodiment 2 and embodiment 1 is: the weight percent of keratin powder in the first finishing solution is 4%; the weight percent of ethylenediamine-modified polylactic acid in the second finishing solution is 2%, and the The weight ratio of amine to ethylenediamine-modified polylactic acid is 0.1:1; S2: immerse the wool fabric in the first finishing solution for 3 hours at room temperature, take out the fabric, and heat it to 70°C under vacuum to dry it; S3: Pad the woolen fabric twice in the second finishing solution, take it out, and dry it at a temperature lower than 70°C.

[0031] The weight percentage of the organic acid in the first finishing solution is 70%; the second finishing solution contains a plasticizer tributyl citrate, and the weight ratio of the plasticizer to ethylenediamine-modified polylactic acid is 0.01:1.

Embodiment 3

[0033] The difference between embodiment 3 and embodiment 1 is: the weight percent of keratin powder in the first finishing solution is 2.5%; the weight percent of ethylenediamine-modified polylactic acid in the second finishing solution is 1.1%, polycarbodiimide The weight ratio of amine to ethylenediamine-modified polylactic acid is 0.65:1; S2: Immerse the wool fabric in the first finishing solution for 2 hours at room temperature, take out the fabric, and heat it to 65°C under vacuum to dry it; S3: Pad the woolen fabric twice in the second finishing solution, take it out, and dry it at a temperature lower than 70°C.

[0034] The weight percentage of the organic acid in the first finishing solution is 80%; the second finishing solution contains a plasticizer, acetyl tributyl citrate, and the weight ratio of the plasticizer to ethylenediamine-modified polylactic acid is 0.02:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com