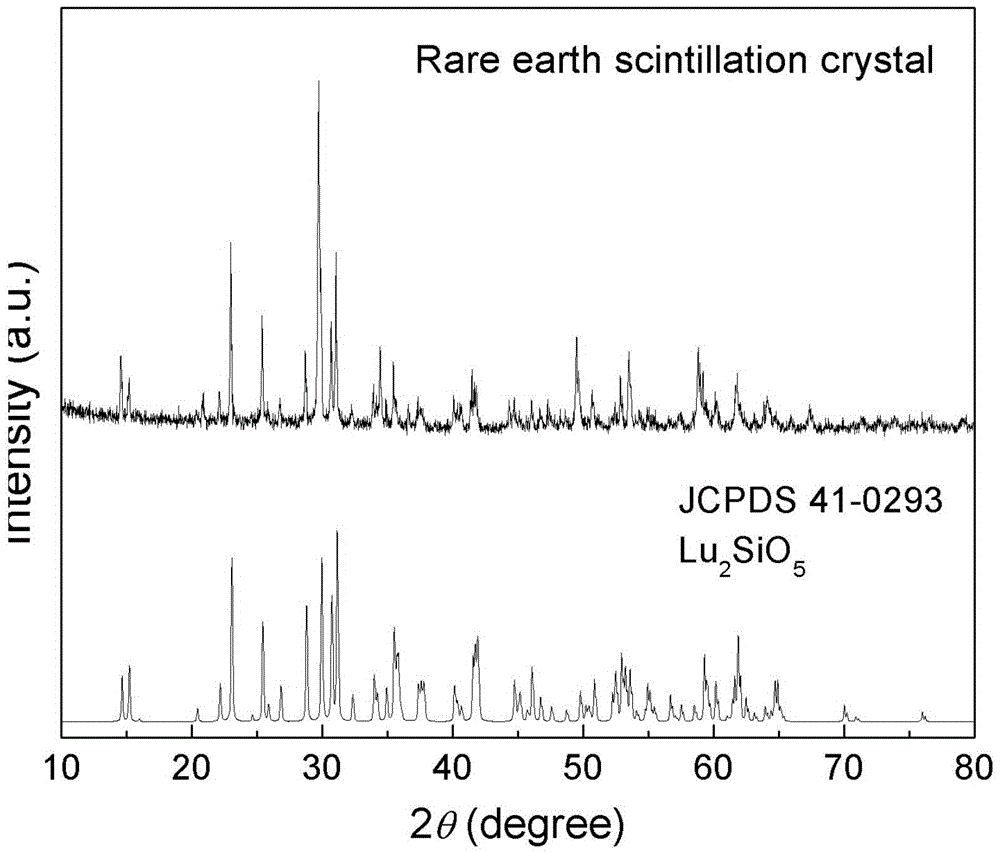

Rare earth scintillation crystal prepared from low-cost rare earth raw materials and low-cost growth process of rare earth scintillation crystal

A technology of scintillation crystal and crystal growth, which is applied in the directions of crystal growth, single crystal growth, single crystal growth, etc., and can solve problems hindering the application in the detection field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] According to the above raw material preparation process, the trivalent cerium ion-doped yttrium lutetium silicate crystal polycrystalline raw material is prepared. The high temperature solid phase reaction is as follows:

[0077] 2xO 2 +yY 2 o 3 +(1-x-y)Lu 2 o 3 +SiO2 2 →(Ce x Lu 1-x-y Y y ) 2 SiO 5 +1 / 2O 2 ↑

[0078] Lu with a purity of 99.9% 2 o 3 , Y 2 o 3 , CeO 2 and SiO 2 , after three-stage series crystallization, Lu with a purity greater than 99.995% was obtained 2 o 3 , Y 2 o 3 , CeO 2 and SiO 2 High-purity raw materials, according to (CeYLu) 2 o 3 :SiO2 2 = 1.1, CeO 2 :( 2 o 3 +Lu 2 o 3 )=0.01, Y 2 o 3 :Lu 2 o 3 =0.18 Proportioning Accurately weigh 2400g, put into the mixer after batching and fully mix for 28 hours, so that the raw materials are evenly mixed. Press the raw material cake under 30MPa, put the raw material cake into the high-purity crucible, and then put it into a part of the reducing atmosphere N 2 +H 2Sinter...

Embodiment 2

[0083] According to the above raw material preparation process, the trivalent cerium ion-doped yttrium lutetium silicate crystal polycrystalline raw material is prepared. The high temperature solid phase reaction is as follows:

[0084] 2xO 2 +yY 2 o 3 +(1-x-y)Lu 2 o 3 +SiO2 2 →(Ce x Lu 1-x-y Y y ) 2 SiO 5 +1 / 2O 2 ↑

[0085] Lu with a purity greater than 99.995% 2 o 3 , Y 2 o 3 , CeO 2 , SiO 2 High-purity raw materials according to (CeYLu) 2 o 3 :SiO2 2 =0.85, CeO 2 :( 2 o 3 +Lu 2 o 3 )=0.008, Y 2 o 3 :Lu 2 o 3 =0.15 Proportioning Accurately weigh 2400g, put into the mixer after batching and fully mix for 28 hours, so that the raw materials are evenly mixed. Press the raw material cake under 30MPa, put the raw material cake into the high-purity crucible, and then put it into a part of the reducing atmosphere N 2 +H 2 Sintering at 1100°C under protection to form a polycrystalline block. The cerium-doped yttrium-lutetium silicate crystal is direc...

Embodiment 3

[0088] According to the above raw material preparation process, the gadolinium lutetium silicate crystal polycrystalline raw material doped with trivalent cerium ions is prepared. The high temperature solid phase reaction is as follows:

[0089] 2xO 2 +yGd 2 o 3 +(1-x-y)Lu 2 o 3 +SiO2 2 →(Ce x Lu 1-x-y Gd y ) 2 SiO 5 +1 / 2O 2 ↑

[0090] Lu with a purity greater than 99.99% 2 o 3 、Gd 2 o 3 , CeO 2 , SiO 2 High-purity raw materials according to (CeGdLu) 2 o 3 :SiO2 2 =1.15, CeO 2 :( 2 o 3 +Lu 2 o 3 )=0.03, Gd 2 o 3 :Lu 2 o 3 =0.15 Proportioning Accurately weigh 5500g, put into a mixer and mix thoroughly for 48 hours after batching, so that the raw materials are evenly mixed. Press the raw material cake under 55MPa, put the raw material cake into the high-purity crucible, and put it into the partial reducing atmosphere N 2 +H 2 Sintering at 1100°C under protection to form a polycrystalline block. Directional pulling and growth of cerium-doped yttri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com