Environment-friendly coal saving agent

A coal-saving agent and environmental protection technology, which is applied in the field of coal chemical industry, can solve the problems of limited coal-saving effect, poor combustion durability, and high safety risk, and achieve the effects of good environmental protection and energy saving, promotion of full combustion, and excellent cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

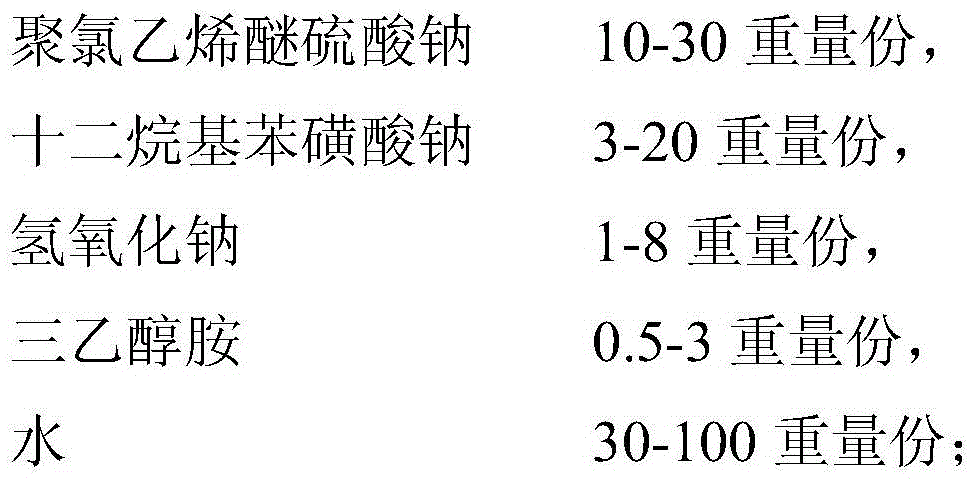

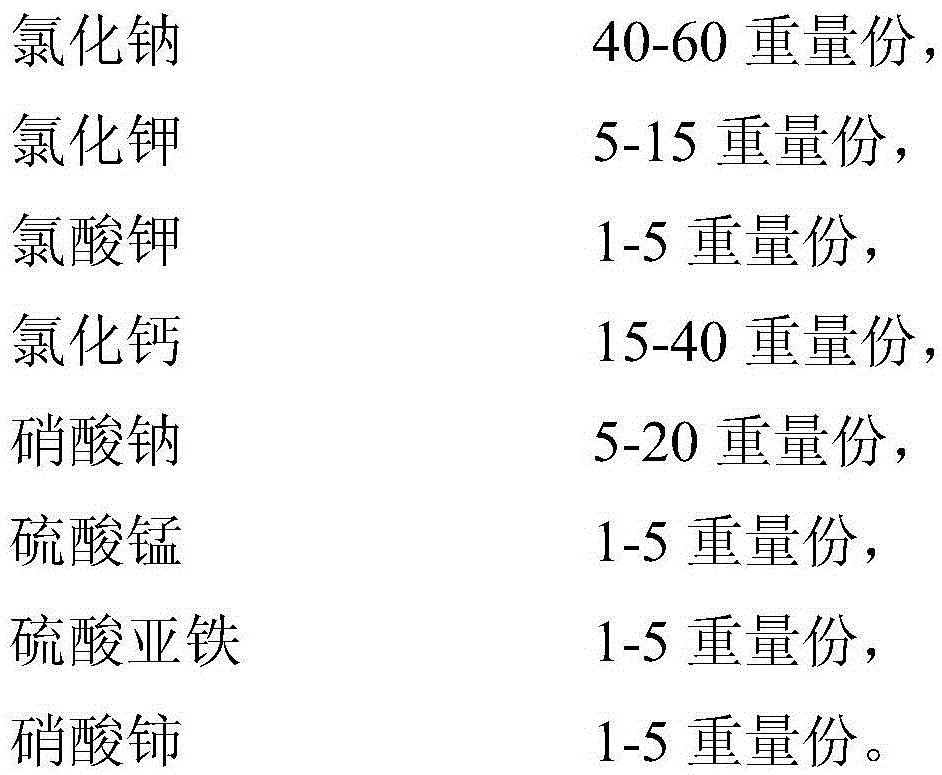

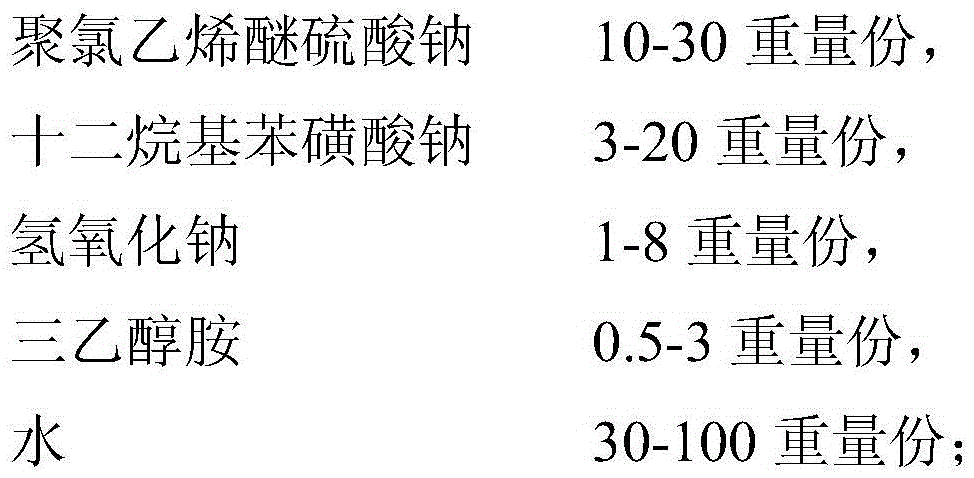

[0036] Correspondingly, the present invention also provides a preparation method of the above-mentioned environmental protection and coal-saving agent, comprising the following steps: mixing 10-30 parts by weight of sodium polyvinyl chloride ether sulfate, 3-20 parts by weight of sodium dodecylbenzenesulfonate , 1-8 parts by weight of sodium hydroxide, 0.5-3 parts by weight of triethanolamine and 30-100 parts by weight of water are mixed to obtain component A after stirring; 40-60 parts by weight of sodium chloride, 5-15 parts by weight The potassium chloride of parts by weight, the potassium chlorate of 1-5 parts by weight, the calcium chloride of 15-40 parts by weight, the sodium nitrate of 5-20 parts by weight, the manganese sulfate of 1-5 parts by weight, the sulfuric acid of 1-5 parts by weight The ferrous iron and 1-5 parts by weight of cerium nitrate are pulverized, mixed and stirred to obtain component B; the components A and B are mixed with 600-3500 parts by weight of...

Embodiment 1

[0053] Preparation process of component A

[0054] The pure water of 70 parts by weight is added in the container, then the sodium dodecylbenzenesulfonate of 18 parts by weight of polyvinyl chloride ether sulfate, the sodium dodecylbenzenesulfonate of 8 parts by weight, the sodium hydroxide of 3 parts by weight, the three Add ethanolamine into the container respectively, stir, and obtain component A after the raw materials are completely dissolved.

Embodiment 2

[0056] Preparation process of component B

[0057] With the sodium chloride of 45 parts by weight, the potassium chloride of 10 parts by weight, the potassium chlorate of 2 parts by weight, the calcium chloride of 25 parts by weight, the sodium nitrate of 10 parts by weight, the manganese sulfate of 2 parts by weight, the sulfuric acid of 3 parts by weight Ferrous iron and 3 parts by weight of cerium nitrate were added into a pulverizer for pulverization, mixed, and evenly stirred to obtain component B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com