Low tar biomass gasification power generation system

A technology of power generation system and low tar, which is applied in fuel oil system, gasification process, gaseous engine fuel, etc., can solve the problems of small gasification scale, difficulty in enlarging the system scale, poor stability of gas quality, etc., and improve the energy conversion rate. , the effect of saving fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

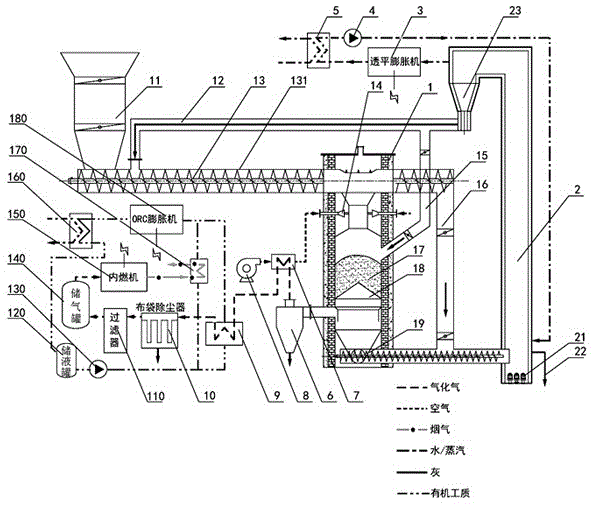

[0017] The patent of the present invention introduces a circulating fluidized bed, and by burning and activating the coke deposited and deactivated after the catalytic reaction of tar in the gasification bed, the original deactivated ash can be activated and the energy of the original coke can be released at the same time Recycle, and recycle the ash with catalytic effect, and use the heat storage function of ash to pyrolyze the biomass feed. Increased by 1 to 2 orders of magnitude, and through the addition of a large amount of catalytically active residual carbon, the biomass material can realize the catalytic modification of the primary pyrolysis tar during the pyrolysis process, which is beneficial to the further removal of tar in the subsequent process.

[0018] Such as figure 1 The schematic diagram of the low-tar biomass gasification power generation system shown is mainly composed of a two-stage downdraft low-tar gasifier 1, a feed hopper 11, an ash return auger 12, a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com