Thermal-inductive fluorocarbon function coating containing azobenzene/carbon-hybrid material and preparation method of thermal-inductive fluorocarbon function coating

A technology of functional coatings and azobenzene, which is applied in the field of heat-sensitive fluorocarbon functional coatings and its preparation, can solve the problems of not having the function of self-storage and heat release, achieve excellent weather resistance, reduce power consumption, and reduce power consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

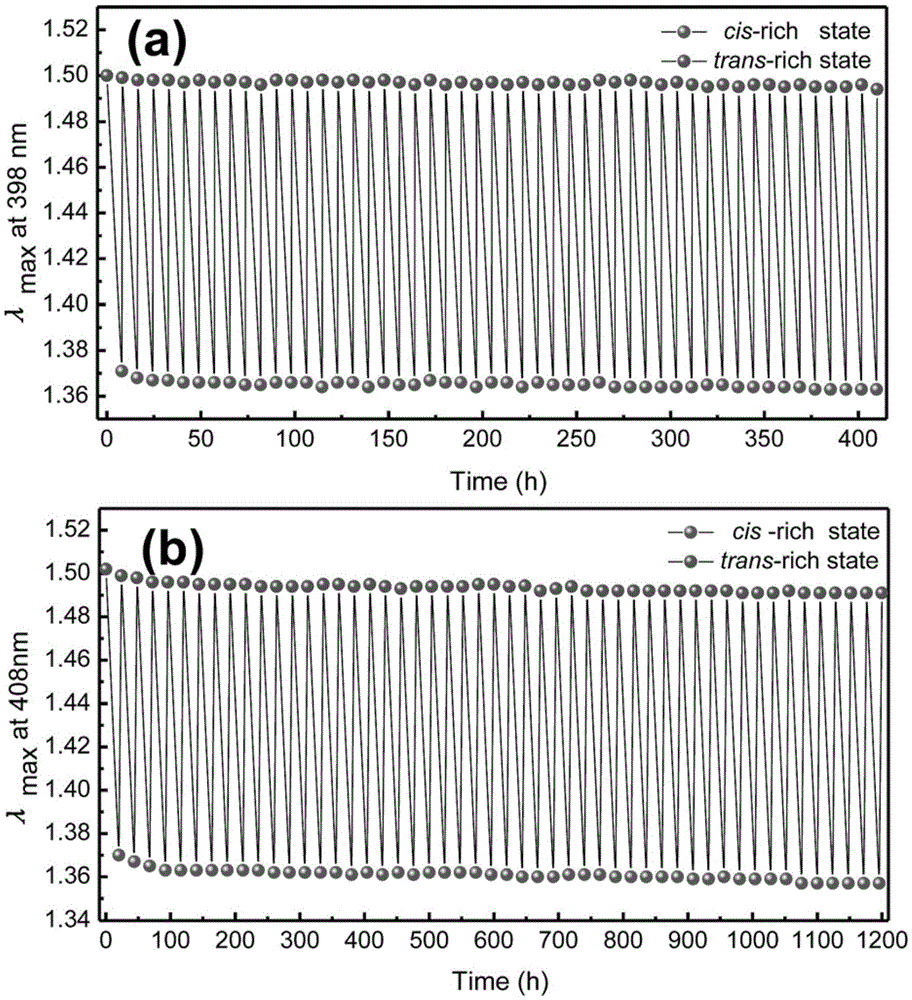

Image

Examples

Embodiment 1

Matting agent

[0059] The structural formula of AZO is selected from:

[0060]

[0061] The preparation process of RGO-AZO is as follows:

[0062] (1) Weigh 10mmol of 5-aminoisophthalic acid (also can be 10mmol of 5-aminoresorcinol, 5-aminoresorcinol), 10.5mmol of NaOH, 100ml of deionized water into a beaker, ultrasonically dissolve; Equimolar NaNO with anthranilic acid 2 Dissolve in 50 mL and add the previous solution. Place the beaker in an ice bath to lower the temperature to 0-5°C; under stirring, slowly add this solution dropwise to 40ml of 1M HCl solution, the temperature is controlled at 0-5°C, and stir for 1 hour to obtain a diazonium salt solution .

[0063] (2) Weigh 3,5-diethoxyaniline (also can be equimolar 3,5-dimethoxyaniline, 3,5-dimethylaniline) with 5-aminoisophthalic acid equimolar, Add 1ml of concentrated HCL solution and 50ml of deionized water into the flask, stir to dissolve it under ice bath conditions, slowly add the diazonium salt soluti...

Embodiment 2

Matting agent

[0070] Wherein the structural formula of AZO in the embodiment two is selected from

[0071]

[0072] The preparation process of RGO-AZO is as follows:

[0073] (1) Weigh 10mmol of 3,5-difluoroaniline (also can be 10mmol of 3,5-dibromoaniline, 3,5-dichloroaniline, 3,5-diiodoaniline, 3,5-dinitroaniline), Add 10.5mmol of NaOH and an appropriate amount of deionized water into a beaker, and ultrasonically dissolve; weigh the NaNO equivalent to 3,5-difluoroaniline 2 Dissolve in 50 ml of deionized water and add the previous solution. Place the beaker in an ice bath and lower the temperature to 0-5°C; under stirring, slowly add this solution dropwise into 40ml of 1M HCl solution, the temperature is controlled at 0-5°C, and stir for 2 hours to obtain diazo saline solution.

[0074] (2) Weigh 3,5-bis(trifluoromethyl)aniline (also can be equimolar 3,5-bis(trifluoromethoxy)aniline, 3,5- Difluoroaniline), 1ml concentrated HCL solution, 40ml deionized water we...

Embodiment 3

Matting agent

[0081] Wherein the structural formula of AZO in the embodiment three is selected from

[0082]

[0083] The preparation process of RGO-AZO is as follows:

[0084] ⑴Weigh 10mmol p-aminophenylboronic acid (also can be 10mmol p-aminophenylboronic acid, p-aminobenzoic acid, p-aminobenzenesulfonic acid), 400mgNaOH, appropriate amount of deionized water into a beaker, ultrasonically dissolve; weigh and p-aminophenylboronic acid, etc. moles of NaNO 2 After dissolving in an appropriate amount of deionized water, add the aforementioned solution. Place the beaker in an ice bath and lower the temperature to 0-5°C; under stirring, slowly add this solution dropwise into 40ml of 1M HCl solution, the temperature is controlled at 0-5°C, and stir for 2 hours to obtain diazo saline solution.

[0085] (2) Weigh 3,5-difluoroaniline (or 3,5-dibromoaniline, 3,5-dichloroaniline) which is equimolar to p-aminophenylboronic acid, 1ml concentrated HCL solution, 40ml deionize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com