Transparent matte waterborne polyurethane emulsion preparation method and prepared transparent matte waterborne polyurethane emulsion

A water-based polyurethane, transparent and matte technology, applied in the field of coatings, can solve the problems of water resistance decline, paint film gloss reduction, wall whitening, etc., and achieve good compatibility, high transparency, and large roughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

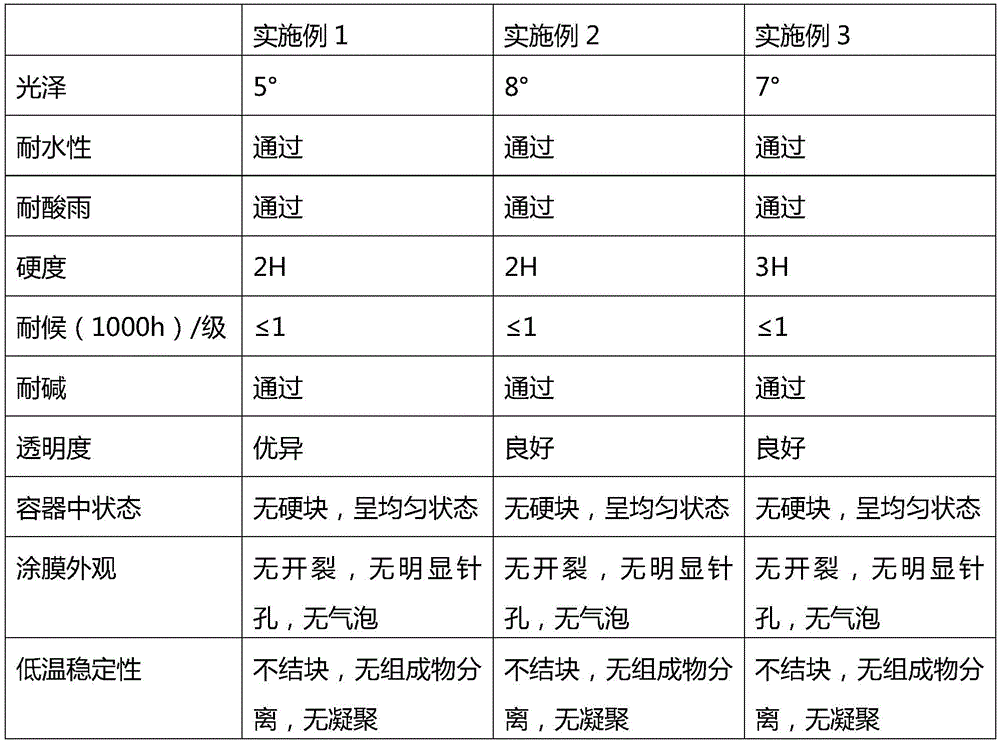

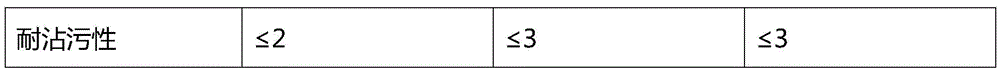

Examples

Embodiment 1

[0026] A preparation method of transparent matte water-based polyurethane emulsion, comprising the following steps:

[0027] Step 1: Vacuumize and dehydrate 2,2-dimethylolpropionic acid (DMPA) and polycarbonate diol at 110°C for 1.2h, with a vacuum degree of 0.08mPa, to obtain prepolymer 1;

[0028] Step 2: Put the DMPA and polycarbonate diol obtained in step 1 into the reaction kettle, and add hexamethylene diisocyanate (HDI) and catalyst dibutyltin dilaurate (DBTDL) under the condition of 70°C and nitrogen protection ) reaction 2.2h;

[0029] Step 3: Detect the NCO content in the reactor, and when the NCO content reaches 90% of the theoretical value, cool down to 58°C; the molar ratio of the DMPA to polycarbonate diol is 2.5:1; the hexamethylene diol The molar ratio of isocyanate and polycarbonate diol is 0.4:1; The amount of catalyst added is 0.015% of the mass of the prepolymer obtained after step 1 treatment;

[0030] Step 4: Add neutralizing agent triethylamine to prep...

Embodiment 2

[0034] A preparation method of transparent matte water-based polyurethane emulsion, comprising the following steps:

[0035] Step 1: Vacuum dehydrate 2,2-dimethylolpropionic acid (DMPA) and polycarbonate diol at 120°C for 1 hour with a vacuum degree of 0.07mPa to obtain prepolymer 1;

[0036] Step 2: Put the DMPA and polycarbonate diol obtained in step 1 into the reaction kettle, and add hexamethylene diisocyanate (HDI) and catalyst dibutyltin dilaurate (DBTDL) under the condition of 80°C and nitrogen protection. ) reaction 2h;

[0037] Step 3: Detect the NCO content in the reactor, and when the NCO content reaches 85% of the theoretical value, cool down to 60°C; the molar ratio of the DMPA to the polycarbonate diol is 3:1; the hexamethylene diol The molar ratio of isocyanate and polycarbonate diol is 0.5:1; The amount of catalyst added is 0.02% of the mass of the prepolymer obtained after step 1 treatment;

[0038] Step 4: Add neutralizing agent triethylamine to prepolymer ...

Embodiment 3

[0042] A preparation method of transparent matte water-based polyurethane emulsion comprises the following steps:

[0043] Step 1: Vacuum dehydrate 2,2-dimethylolpropionic acid (DMPA) and polycarbonate diol at 100°C for 1 hour with a vacuum degree of 0.9mPa to obtain prepolymer 1;

[0044] Step 2: Put the DMPA and polycarbonate diol obtained in Step 1 into the kettle, and add isophorone diisocyanate and catalyst dibutyltin dilaurate (DBTDL) to react for 2.5 hours under the condition of 60°C and nitrogen protection;

[0045] Step 3: Detect the NCO content in the reaction kettle of the system, and when the NCO content reaches 95% of the theoretical value, cool down to 55°C; the molar ratio of the DMPA to the polycarbonate diol is 2:1; the isophorone The mol ratio of diisocyanate and polycarbonate diol is 0.3:1; The catalyst addition is 0.01% of the prepolymer mass obtained after step 1 treatment;

[0046] Step 4: Add neutralizing agent triethylamine to prepolymer 2 obtained aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com