Industrial production method of secondary glycoside of dioscin

A technology of diosgenin and production method, applied in the fields of medicinal chemical engineering and natural products, can solve the problems of difficult separation, environmental pollution, large solvent and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

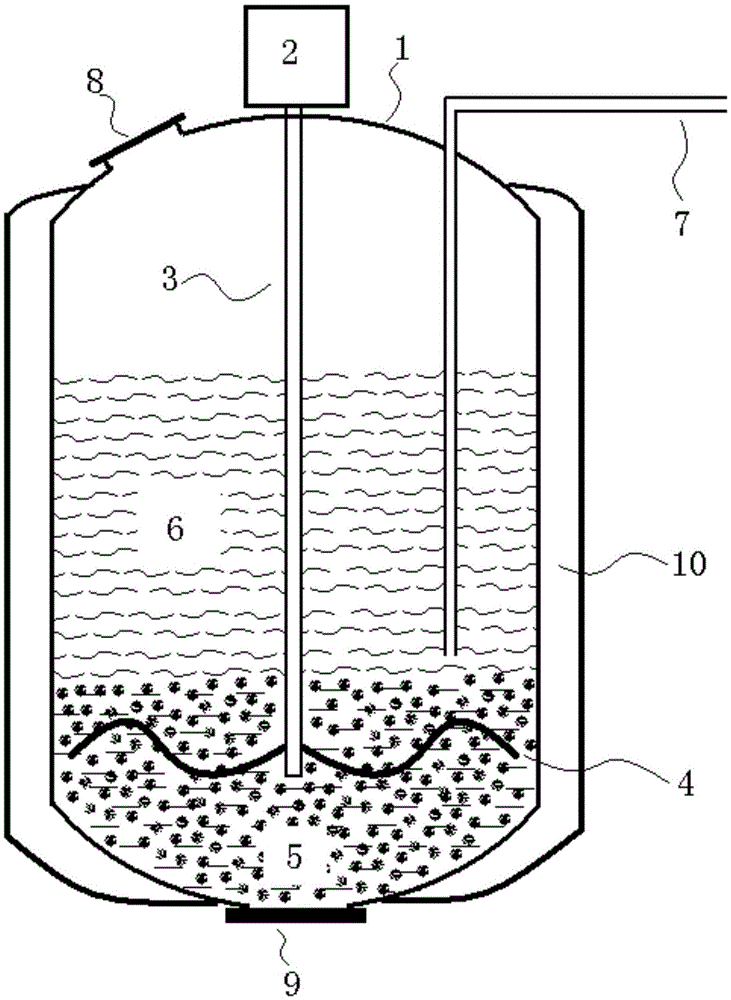

[0025] Such as figure 1 As shown, a device used in the industrial production reaction system of diosgenin secondary glycosides, including an acid-resistant reaction tank 1, a stirring motor 2, a stirring rod 3, a stirring screw 4, an acid aqueous phase suspension 5, and a n-butanol phase 6 , Suction tube / filling tube 7, feed port cover 8, discharge port cover 9 and heating layer 10.

[0026] The inner wall of the acid-resistant reaction tank, the stirring rod 3 and the stirring spiral piece 4 are all ceramic coating or tetrafluoroethylene coating.

[0027] The inner layer of the discharge port cover and the inner and outer layers of the suction pipe are both ceramic coating or tetrafluoroethylene coating.

[0028] The acid water suspension phase 5 may be sulfuric acid water, hydrochloric acid water, nitric acid water, sulfurous acid water, nitrous acid water, etc.

Embodiment 2

[0030] A kind of industrialized production method of diosgenin secondary glycoside is as follows:

[0031] (1) 15 tons of fresh yam rhizomes are smashed, soaked with 70-95v / v% ethanol, then filtered to obtain an ethanol extract, and dried and crushed to obtain 1 ton of ethanol extract, then extracted with water-saturated n-butanol Ethanol extract powder, concentrate n-butanol extract to obtain n-butanol extract, i.e. dioscin extract, or extract ethanol extract powder with water-saturated ethyl acetate, and then concentrate to obtain ethyl acetate extract, i.e. dioscin extract liquid;

[0032](2) Preparation of acidic water phase: 98wt% vitriol oil or 37wt% concentrated hydrochloric acid are added to pure water or common tap water to obtain acidic water phase; the volume ratio of 98wt% vitriol oil or 37wt% concentrated hydrochloric acid to pure water or common tap water is 0.2:10, prepare 5-8 tons of acidic aqueous phase;

[0033] (3) Add the acidic aqueous phase prepared in ...

Embodiment 3

[0039] A kind of industrialized production method of diosgenin secondary glycoside is as follows:

[0040] (1) 28 tons of fresh yam rhizomes are added with water-saturated n-butanol to make a pulp, and the pulp residue is added in a sufficient amount of water in the sedimentation tank to make n-butanol layered, and then the n-butanol in the upper layer is extracted to obtain n-butanol of dioscin Alcohol extract, the main component of which is diosgenin;

[0041] (2) Preparation of acidic water phase: 98wt% vitriol oil or 37wt% concentrated hydrochloric acid are added to pure water or common tap water to obtain acidic water phase; the volume ratio of 98wt% vitriol oil or 37wt% concentrated hydrochloric acid to pure water or common tap water is 0.1:10, prepare 5-8 tons of acidic aqueous phase;

[0042] (3) Add the acid water phase prepared in step (2) into a reaction tank with a capacity of 20 tons, and add the n-butanol extract of dioscin prepared in step 1) in the reaction ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com