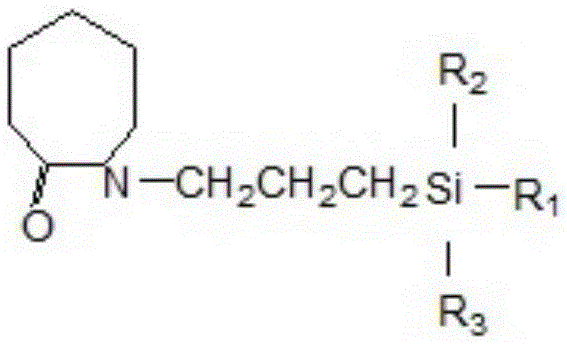

Caprolactamyl silane and preparation method thereof

A caprolactam-based silane technology, applied in the field of caprolactam-based silane and its preparation, can solve the problems of poor compatibility, low strength and the like, and achieve the effects of low cost, fast dispersion and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In order to maintain the activity of the substance and have good compatibility in polyamide, a caprolactam-based silane has been developed in this program. The caprolactam group in the silane has a good synergistic effect with the structure in polyamide, which is beneficial to The increase in strength of polyamide resins is superior to that of conventional aminosilanes.

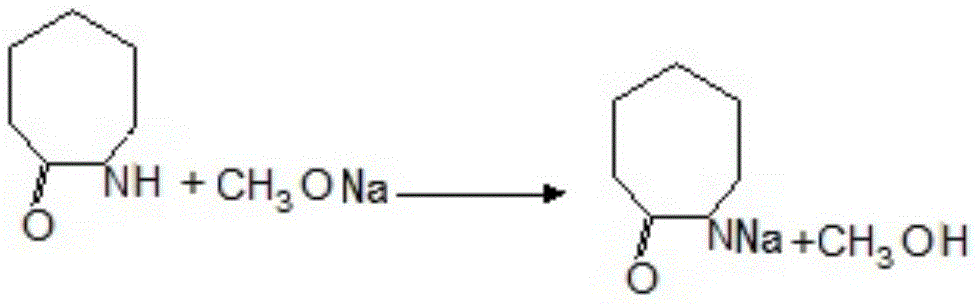

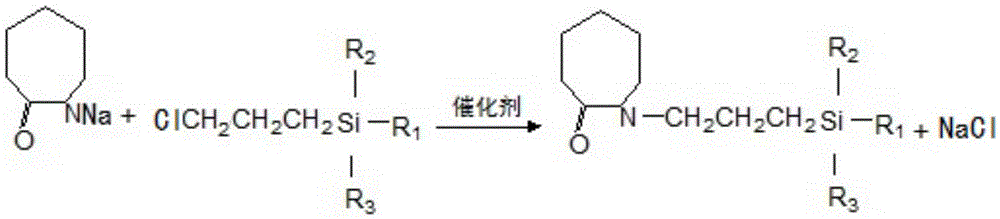

[0031] The specific steps of making the required caprolactam-based silane are as follows:

[0032] (1) Add 56 grams of caprolactam, 90 grams of methanol solution of 30% mass fraction sodium methoxide, and 220 grams of benzene in a three-necked flask with a stirring device, stir and heat up, keep warm at 50° C. for 24 hours, and cool to room temperature. After filtering and stirring the reaction, the temperature of the reaction liquid is lowered and cooled, and finally the solid salt is obtained by filtration, and the solid salt is dried to obtain caprolactam sodium salt, which is set aside.

[0033] (...

Embodiment 2

[0043] (1) Add 75 grams of caprolactam, 120 grams of methanol solution of 30% mass fraction sodium methoxide, and 310 grams of benzene in a three-necked flask with a stirring device, stir and heat up, keep warm at 90° C. for 2 hours, and cool to room temperature. After filtering and stirring the reaction, the temperature of the reaction liquid is lowered and cooled, and finally the solid salt is obtained by filtration, and the solid salt is dried to obtain caprolactam sodium salt, which is set aside.

[0044] (2) Put 68 grams of caprolactam sodium salt prepared above into a three-necked flask with a reflux device, chloropropyl silane adopts 115 grams of chloropropyl triethoxysilane, and the phase transfer catalyst is trimethylbenzyl ammonium chloride 1.8 grams, the organic solvent here is 190 grams of N,N-dimethylacetamide, start to stir and heat up, keep the temperature at 150°C for 1 hour, and cool down to room temperature after the reaction;

[0045] (3) filter, can produce...

Embodiment 3

[0048] (1) Add 70 grams of caprolactam, 110 grams of methanol solution of 30% mass fraction sodium methoxide, and 280 grams of benzene in a three-necked flask with a stirring device, stir and heat up, keep warm at 70° C. for 12 hours, and cool to room temperature. After filtering and stirring the reaction, the temperature of the reaction liquid is lowered and cooled, and finally the solid salt is obtained by filtration, and the solid salt is dried to obtain caprolactam sodium salt, which is set aside.

[0049](2) Put 50 grams of caprolactam sodium salt prepared above into a three-necked flask with a reflux device, chloropropyl silane adopts 80 grams of chloropropyl triisopropoxysilane, and the phase transfer catalyst is trioctylmethyl chloride 1.6 grams of ammonium, the organic solvent here is 170 grams of dimethyl sulfoxide, start to stir and heat up, keep warm at 120 ° C for 2 hours, and cool down to room temperature after the reaction;

[0050] (3) filter, can produce by-pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com