Preparation method and application for fly ash based polymer cementing material and porous concrete material

A technology of polymer glue and fly ash, which is applied in the field of building materials, can solve the problems of difficult balance between road bearing capacity and functionality, shortening the service life of road slabs, and difficulty in achieving flexural strength, etc., achieving remarkable effects of water permeability and noise reduction , Realize the comprehensive utilization of resources, meet the effect of industrial production and construction requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A certain basalt gravel composed of 4.75~9.5mm:9.5~16.0mm (standard square hole sieve)=7:3 particle size is used, and its tapped density is 1722kg / m 3 , choose unit aggregate volume ratio 0.96, then 1m 3 The dosage of porous concrete basalt gravel is 1722×0.96=1653kg; water-binder ratio is 0.36; Amount 15%), nanometer zeolite powder is 12kg (doping amount 5%); The compound alkali excitation component of potassium sodium water glass and caustic alkali is 36kg (15% of cementing material consumption), modulus M=z / (x+ y) = 1.4.

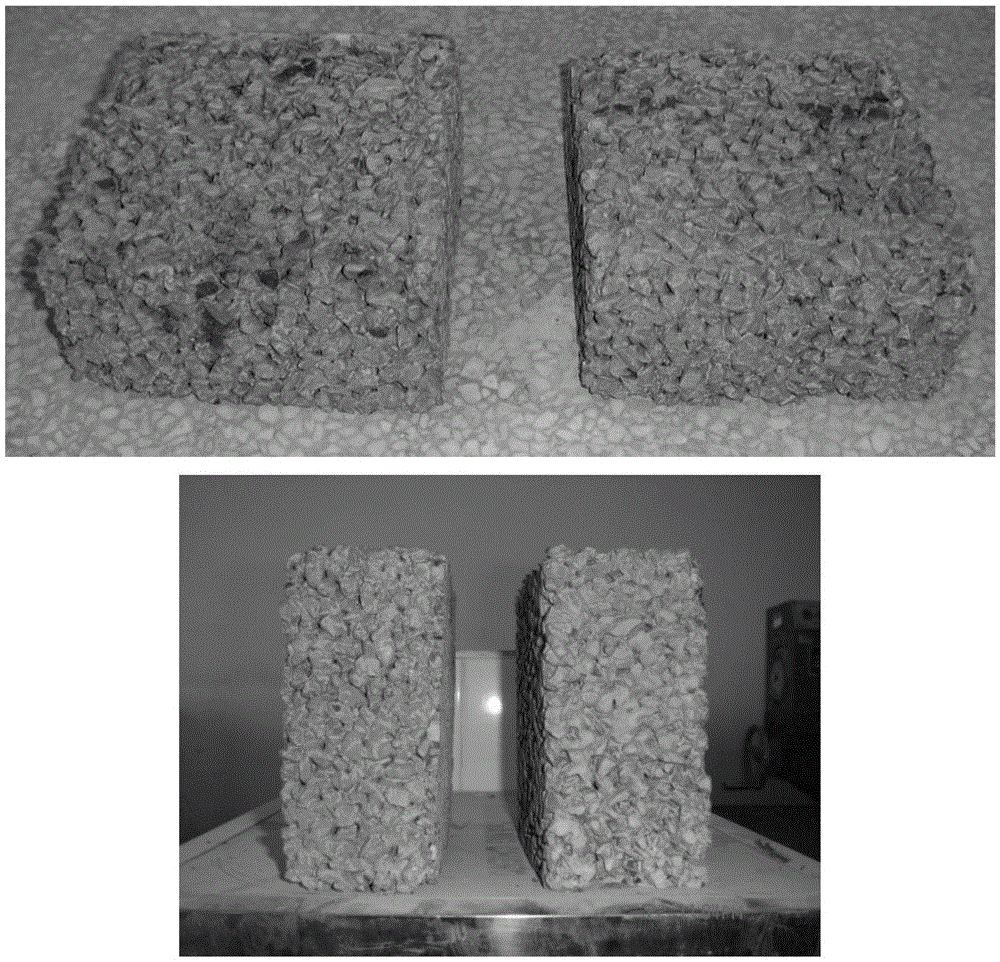

[0041] The 28-day-old fly ash-based polymer porous concrete formed by vibratory compaction is averagely cut along the depth direction, and the pore state in the middle of the specimen can be found in figure 1 . The internal pores of porous concrete are evenly distributed, the measured connected porosity is 20.3%, the depth of the surface anti-skid structure is 1.3mm, the measured water permeability coefficient of the constant water head method i...

Embodiment 2

[0043] Use a certain granite gravel composed of 4.75~9.5mm: 9.5~16.0mm (standard square hole sieve) = 7:3 particle size, and its tapped density is 1674kg / m 3 , choose unit aggregate volume ratio 0.92, then 1m 3 The amount of porous concrete granite crushed stone is 1674×0.92=1540kg; the water-binder ratio is 0.32; the amount of fly ash base polymer cementitious material is 310kg, of which the amount of class I and F fly ash is 233kg (75%), S95 granulation Blast furnace slag is 31kg (amount 10%), nanometer zeolite powder is 31kg (amount 10%), and desulfurized gypsum powder is 15.5kg (amount 5%); 62kg (20% of the amount of cement used), modulus M = 1.6.

[0044] The measured connected porosity of porous concrete is 18.4%, the surface anti-skid structure depth is 1.2mm, the water permeability coefficient measured by the constant water head method is 4.9mm / s, the water permeability coefficient tested by the road permeable meter is 1108mL / 15s, and the average vertical sound absorp...

Embodiment 3

[0052] Select 30 groups of porous concrete successfully prepared for highway combined double-layer concrete surface, and make statistics on the amount of each component material. The market price of non-pumped C35 ordinary cement concrete is about 250 yuan / m 3 Second, the market price of its cementitious material cement is 440-500 yuan / ton; the market price of fly ash is about 180 yuan / ton, the granulated blast furnace slag powder is about 180 yuan / ton, and the gypsum powder is about 200 yuan / ton. Zeolite powder is 800 yuan / ton, basalt crushed stone is about 200 yuan / ton, and the compound alkali activator made of sodium silicate and caustic alkali is about 100 yuan / m 3 In terms of yuan, the cost of the composite material of fly ash base polymer porous concrete with the same strength level is about 440 yuan / m 3 . The price gap between fly ash base polymer porous concrete and ordinary cement concrete is mainly caused by the different types of coarse aggregate. As far as the ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water permeability coefficient | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com