A construction method of constructed wetland industrialization

A technology of artificial wetlands and construction methods, applied in chemical instruments and methods, botany equipment and methods, agriculture, etc., can solve the problems of insufficient sewage treatment capacity and saturation, and achieve convenient plant root absorption, less land occupation, high The effect of economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

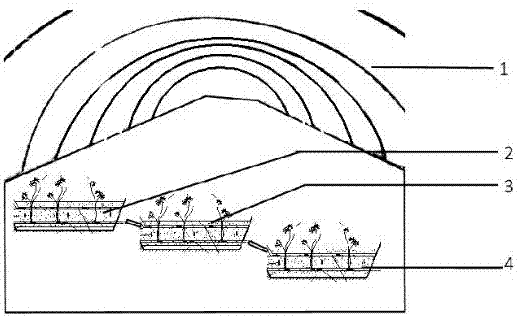

[0035] Such as figure 1 As shown, an industrial construction method of constructed wetland in this embodiment is used to purify domestic sewage and aquaculture wastewater, and produce vegetables or grass at the same time, including:

[0036] (1) Build a plastic greenhouse:

[0037] The plastic greenhouse is composed of white plastic film and steel support. The film is detachable. The width of the greenhouse is 5 meters, the height is 5 meters, and the length is 35 meters. The plastic film is covered when the temperature is lower than 20 ℃, and the plastic film is removed when the temperature is higher than 20 ℃.

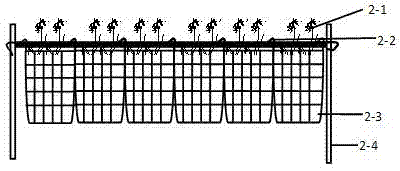

[0038] (2) Construction of multi-level pure hydroponic vertical flow artificial wetland:

[0039] The vertical flow artificial wetland cement pool has a width of 2 meters, the primary purification pool has a length of 5 meters, a height of 60 cm, and a width of 2 meters; the secondary purification pool has a length of 5 meters, a height of 40 cm, and a width of 2 mete...

Embodiment 2

[0049] An industrial construction method of a constructed wetland in this embodiment is used to purify factory sewage and produce economic plants such as lawns and flowers, including:

[0050] (1) Build a plastic greenhouse:

[0051] The plastic greenhouse is composed of white plastic film and steel support. The film is detachable. The width of the greenhouse is 15 meters, the height is 5 meters, and the length is 55 meters. The plastic film is covered when the temperature is lower than 20 ℃, and the plastic film is removed when the temperature is higher than 20 ℃.

[0052] (2) Construction of multi-level pure hydroponic vertical flow artificial wetland:

[0053] The vertical flow artificial wetland cement pool has a width of 2 meters, the primary purification pool has a length of 10 meters, a height of 60 cm, and a width of 2 meters; the secondary purification pool has a length of 20 meters, a height of 30 cm, and a width of 2 meters; the final purification pool has a length ...

Embodiment 3

[0063] An industrial construction method of a constructed wetland in this embodiment is used to purify agricultural non-point source pollution and reclaimed water discharged from sewage treatment plants, including:

[0064] (1) Build a plastic greenhouse:

[0065] The plastic greenhouse is composed of white plastic film and steel support. The film is detachable. The width of the greenhouse is 20 meters, the height is 5 meters, and the length is 15 meters. The plastic film is covered when the temperature is lower than 20 ℃, and the plastic film is removed when the temperature is higher than 20 ℃.

[0066] (2) Construction of multi-level pure hydroponic vertical flow artificial wetland:

[0067] The vertical flow artificial wetland cement pool has a width of 2 meters, the primary purification pool has a length of 5 meters, a height of 30 cm, and a width of 2 meters; the secondary purification pool has a length of 5 meters, a height of 20 cm, and a width of 2 meters; there is no ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com