Forward-backward drawing and forming method for metal plate soft mould

A metal sheet, reverse deep drawing technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of complex mold structure, surface quality and precision limitations of formed products, etc., to reduce bending deformation resistance, prevent internal wrinkles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

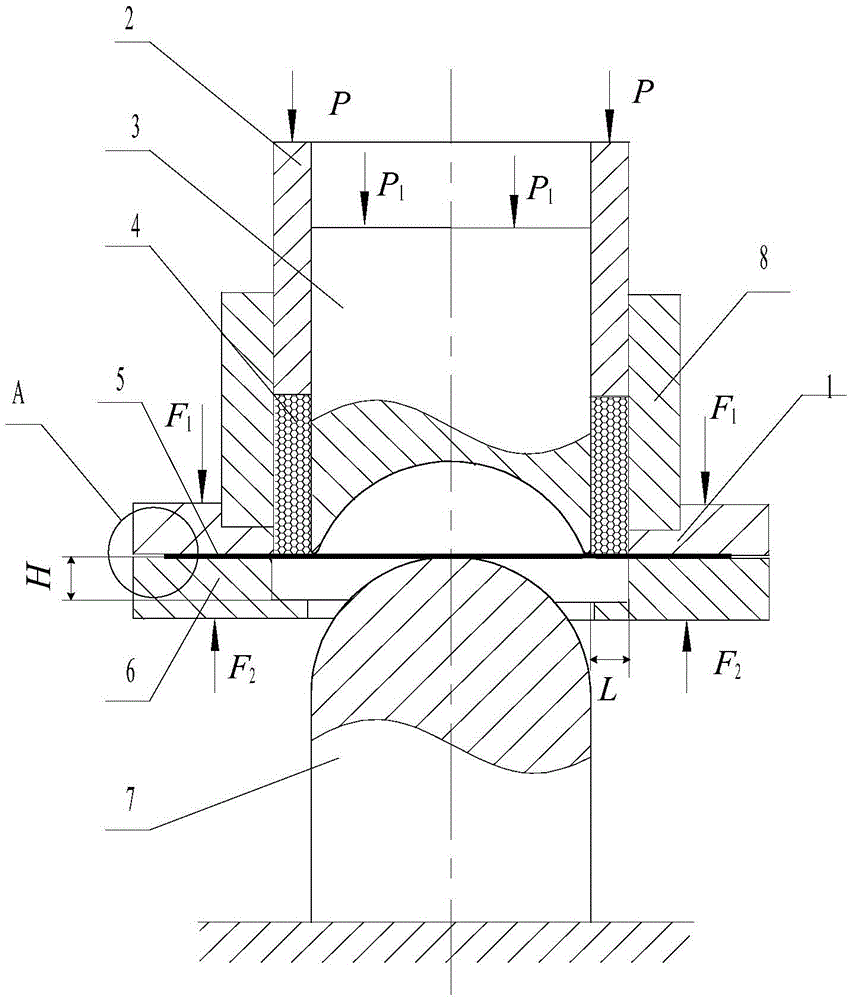

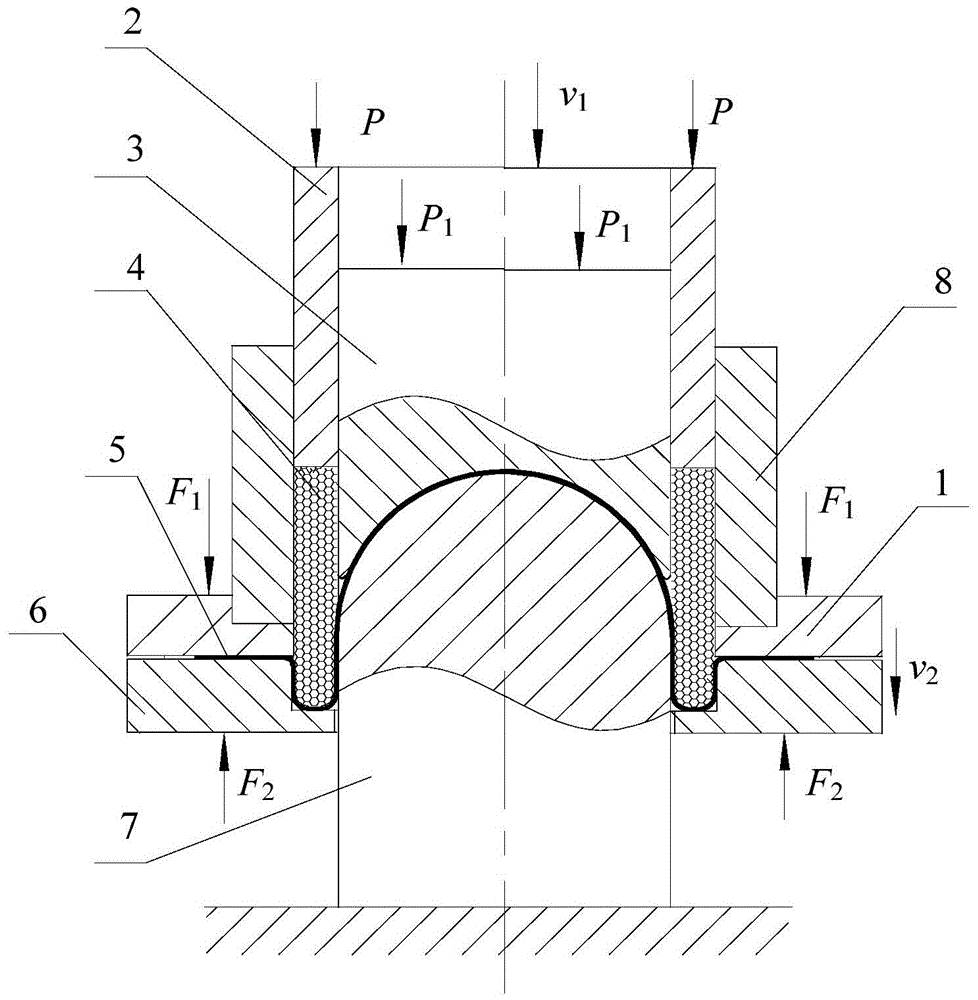

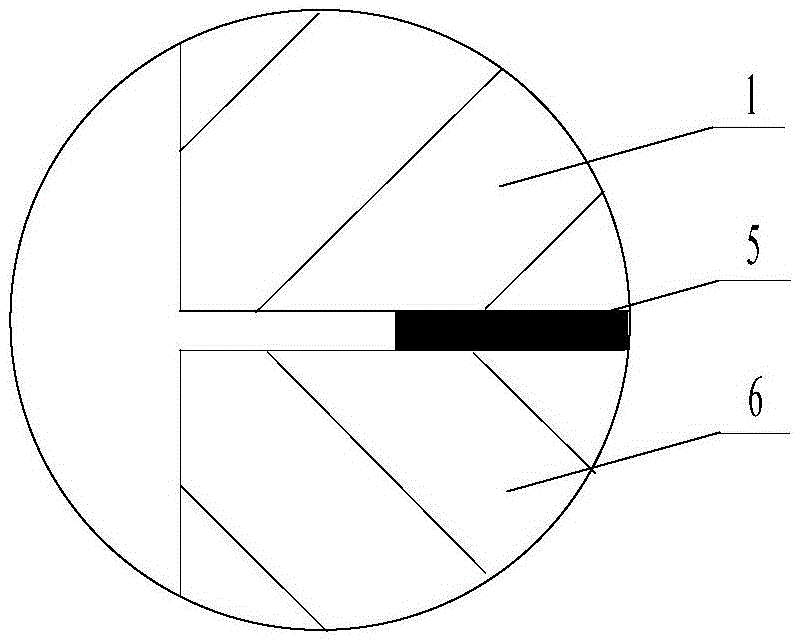

[0030] exist figure 1 In the schematic diagram of the front view section of the mold device before processing of the metal sheet soft mold front and back deep drawing forming method shown, the mold has a cylindrical punch 7 whose lower end is fixed on the forming equipment, and its upper end is shaped as a positive spherical surface. A lower binder ring 6 is set on the outside of the punch, and the lower binder ring is a ring, and the diameter of the central through hole is greater than or equal to the outer diameter of the punch. The circular groove of L is called deep drawing groove. A corresponding upper blankholder 1 is arranged on the lower blankholder, which is also a circular ring, and the diameter of its central through hole = diameter of the punch + width L of the deep drawing groove of the lower blankholder. The central through hole of the binder ring is also provided with an annular groove, which is a connecting groove, and the connecting groove is provided with a ...

Embodiment 2

[0033] exist Figure 4 In the schematic diagram of the front view section of the mold device before the processing of the metal sheet soft mold front and back deep drawing forming method shown, the mold has a cylindrical punch 7 whose lower end is fixed on the mold fixing device, and its upper end is in the shape of a truncated cone. A lower binder ring 6 is set on the outside of the punch, and the lower binder ring is a ring, and the diameter of the central through hole is greater than or equal to the outer diameter of the punch. The circular groove of L is called deep drawing groove. A corresponding upper blankholder 1 is arranged on the lower blankholder, which is also a circular ring, and the diameter of its central through hole = diameter of the punch + width L of the deep drawing groove of the lower blankholder. The central through hole of the binder ring is also provided with an annular groove, which is a connecting groove, and the connecting groove is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com