Ionic liquid-functionalized snowman-shaped anisotropic composite material and preparation method and application thereof

An ionic liquid, anisotropic technology, used in chemical instruments and methods, transportation and packaging, chemical/physical processes, etc., to solve problems such as unpleasant Pickering emulsions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

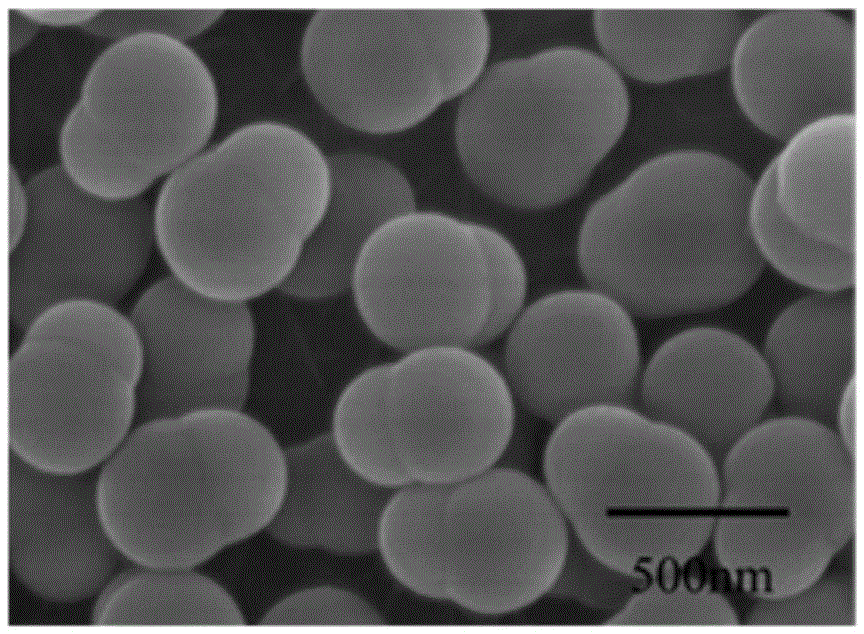

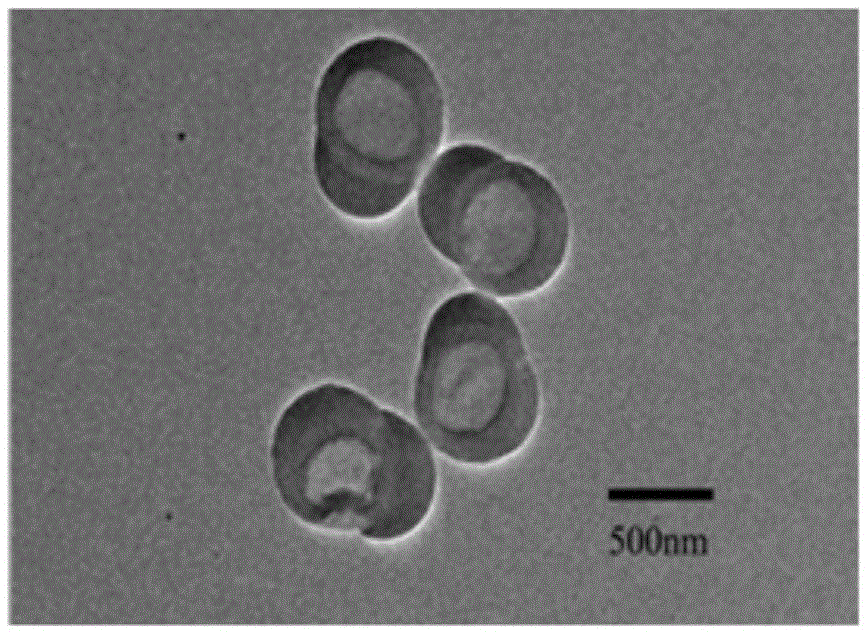

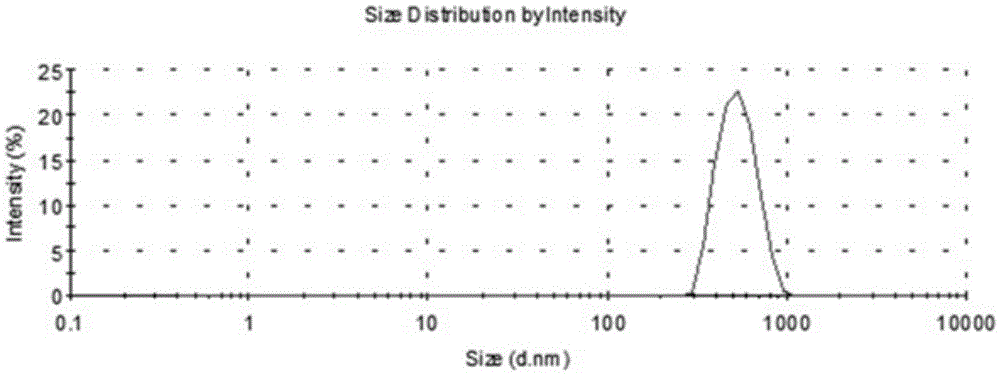

[0040] Example 1Cl - Functionalized Janus snowman-shaped composite particles based on ionic liquid

[0041] (1) The preparation method is as follows

[0042] 1) Polystyrene hollow ball: purchased from Rohm&Haas Company, the product code is HP-433.

[0043] 2) Preparation of Janus snowman-shaped composite particles: take 1g of polystyrene hollow spheres and disperse them in 20g of water, and use NH 3 ·H 2 O (28wt%) adjusts the pH=8 of the solution, and stirs at 70°C to form a seed emulsion; mix 2g3-(methacryloyloxy)propyltrimethoxysilane (MPS), 2g1.0wt% potassium persulfate aqueous solution (KPS) and 0.02g sodium dodecylbenzenesulfonate (SDS) were ultrasonically dispersed in 10g water to form a monomer emulsion; the monomer emulsion was slowly added dropwise into the seed emulsion within 30 minutes, and reacted at 70°C for 12 After ~24 hours, the precipitate was collected by centrifugation, washed three times with water and ethanol respectively, separated by centrifugation ...

Embodiment 2

[0065] Example 2PF 6- Functionalized Janus snowman-shaped composite particles based on ionic liquid

[0066] (1) The preparation method is as follows

[0067] 1) Preparation of polystyrene hollow spheres: purchased from Rohm&Haas Company, the product code is HP-433

[0068] 2) Preparation of Janus snowman-shaped composite particles: same as in Example 1

[0069] 3) Preparation of imidazoline-based modified Janus snowman-shaped composite particles: same as in Example 1

[0070] 4) Cl - Preparation of ionic liquid-based functionalized Janus snowman-shaped composite particles: the same as in Example 1

[0071] 5) PF 6 - Preparation of ionic liquid-based Janus snowman-shaped composite particles: take 10mgCl - Based ionic liquid functionalized Janus snowman composite particles, ultrasonically dispersed in 5ml water, add 20mgKPF 6 , stirred at room temperature for 2h, centrifuged to take the precipitate, washed with water, centrifuged and vacuum dried for 12h to obtain white...

Embodiment 3

[0075] Example 3 Silicotungstic acid-based ionic liquid functionalized Janus snowman-shaped composite particles

[0076] (1) The preparation method is as follows

[0077] 1) Preparation of polystyrene hollow spheres: purchased from Rohm&Haas Company, the product code is HP-433

[0078] 2) Preparation of Janus snowman-shaped composite particles: same as in Example 1

[0079] 3) Preparation of imidazoline-based modified Janus snowman-shaped composite particles: same as in Example 1

[0080] 4) Cl - Preparation of ionic liquid-based functionalized Janus snowman-shaped composite particles: the same as in Example 1

[0081] 5) Preparation of silicotungstic acid-based ionic liquid functionalized Janus snowman-shaped composite particles: take 10mgCl - Based ionic liquid functionalized Janus snowman-shaped composite particles, ultrasonically dispersed in 5ml water, add 200mg silicotungstic acid group (H 3 [Si(W 3 o 10 ) 4 - ]), stirred at room temperature for 2 h, centrifuged...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com