Composition for 3D printed cartilage bracket, microsphere and preparation method of composition

A 3D printing and composition technology, applied in tissue regeneration, medical science, prosthesis, etc., can solve the problems of central nervous system toxicity, strong spasm, life-threatening, etc., and achieve the promotion of cartilage tissue formation, good biocompatibility, The effect of suitable degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

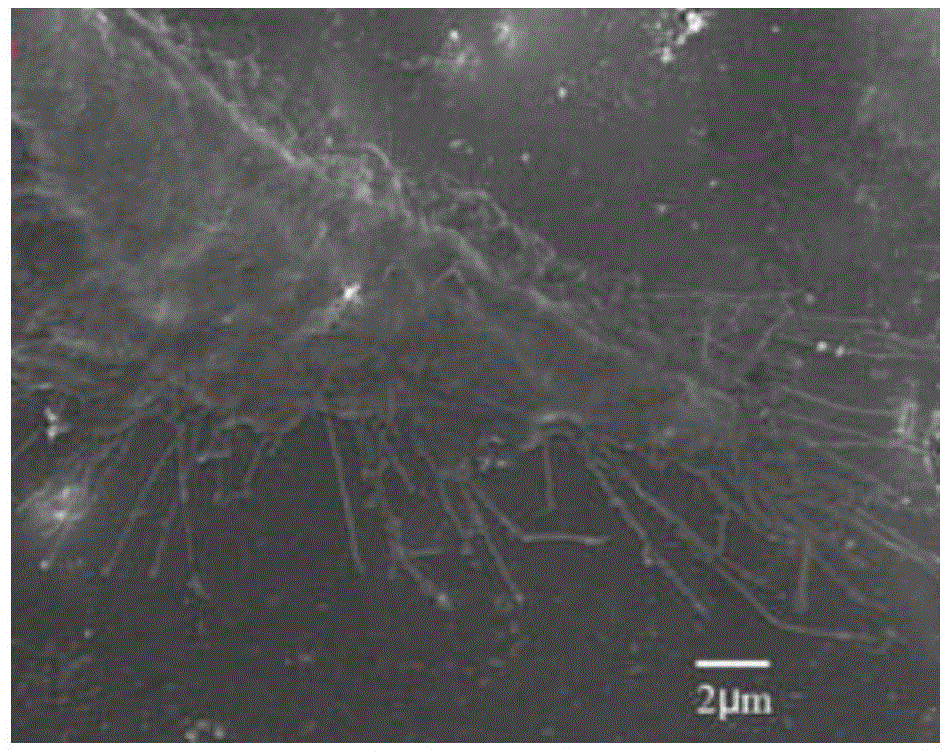

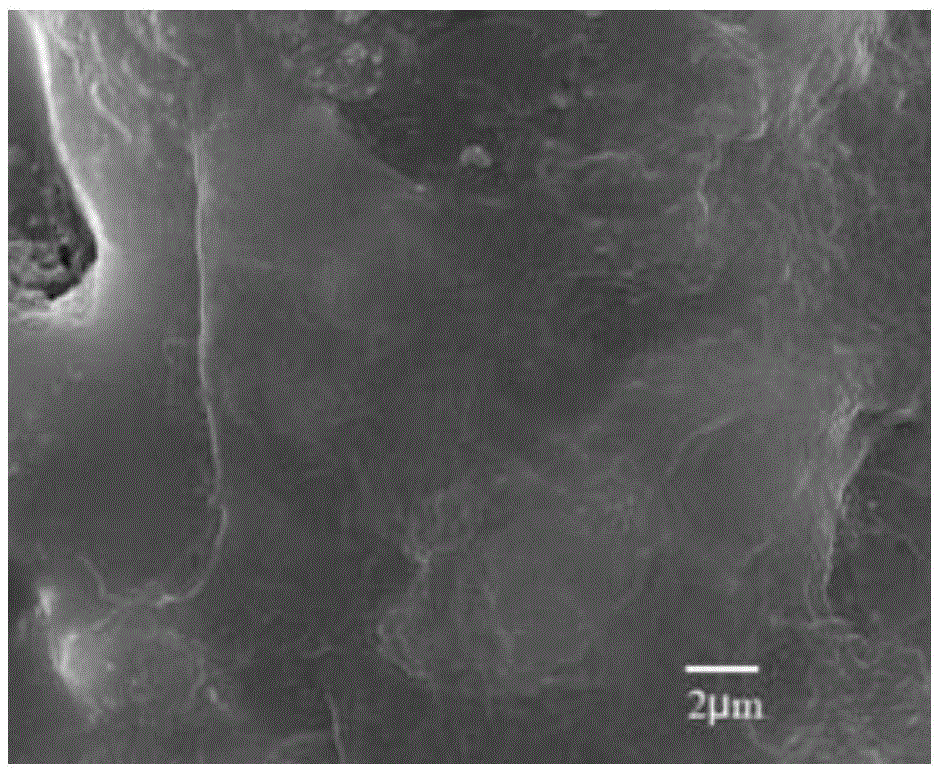

Image

Examples

Embodiment 1

[0056] Put 1 mg of total strychnine alkaloids (also known as strychnine total alkaloids, wherein the content of strychnine is 0.512 mg, and the content of strychnine is 0.453 mg) and 1 mL of ethanol are placed in a 2 mL EP tube , ultrasonic vibration makes it dissolve, obtains the solution 1 that contains the total alkaloid of strychnium, for subsequent use;

[0057] Put 2 mg of PLGA solid in a 2 mL EP tube, add 1 mL of dichloromethane to dissolve it completely, and obtain a dichloromethane solution 2 containing polylactic-glycolic acid, and set aside;

[0058] Place 1 mg of chitosan in 20 mg of 1% by weight PVA aqueous solution, and ultrasonically vibrate to dissolve it to obtain solution IV for subsequent use;

[0059] (1) Mix 100 microliters of solution 1 with all of solution 2 at minus 4°C and keep for 20 minutes to obtain solution I;

[0060] (2) Mix solution I, which is ultrasonicated at minus 4°C for 5 minutes (power is 5W), and 20 mg of 1% by weight PVA aqueous soluti...

Embodiment 2

[0070] Put 0.8mg of strychnine and 1mL of ethanol in a 2mL EP tube, and dissolve them by ultrasonic vibration to obtain solution 1 containing strychnine, which is set aside;

[0071] Put 2.5 mg of PLGA solid in a 2 mL EP tube, add 1 mL of dichloromethane to dissolve it completely, and obtain a dichloromethane solution 2 containing polylactic-glycolic acid, and set aside;

[0072] Place 1.2 mg of chitosan in 25 mg of 1% by weight PVA aqueous solution, and ultrasonically vibrate to dissolve it to obtain solution IV for subsequent use;

[0073] (1) Mix 100 microliters of solution 1 with all of solution 2 at minus 8°C and keep for 20 minutes to obtain solution I;

[0074] (2) Mix solution I, which was ultrasonicated at minus 8°C for 10 minutes (power is 5W), with 20 mg of 1% by weight PVA aqueous solution II at minus 8°C, and ultrasonicate for 80 minutes (power is 8W), to obtain solution III;

[0075] (3) The solution III was contacted with the solution IV for 3.5 hours under sti...

Embodiment 3

[0084] Put 0.4mg of strychnine and 0.3mg of strychnine and 1mL of ethanol in a 2mL EP tube, and dissolve them by ultrasonic vibration to obtain a solution 1 containing strychnine and strychnine, which is set aside;

[0085] Put 1.8mg of PLGA solid into a 2mL EP tube, add 1mL of dichloromethane to dissolve it completely, and obtain a dichloromethane solution 2 containing polylactic-glycolic acid, and set aside;

[0086] Place 0.93 mg of chitosan in 20 mg of 1% by weight of PVA aqueous solution, and dissolve it with ultrasonic vibration to obtain solution IV for subsequent use;

[0087] (1) Mix 100 microliters of solution 1 with all of solution 2 at 0°C and keep for 30 minutes to obtain solution I;

[0088] (2) Mix solution I, which was sonicated at 0°C for 10 minutes (power is 5W), with 18 mg of 1% by weight PVA aqueous solution II at 0°C and sonicate for 100 minutes (power is 5W), to obtain solution III;

[0089] (3) The solution III was contacted with the solution IV for 3 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com