Hydrogel wound dressing and preparation method and application thereof

A wound dressing and hydrogel technology, applied in the field of medical devices, can solve problems such as poor swelling, wound exudate, and poor viscosity, and achieve the effects of no fiber residue, good biocompatibility, and improved water absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

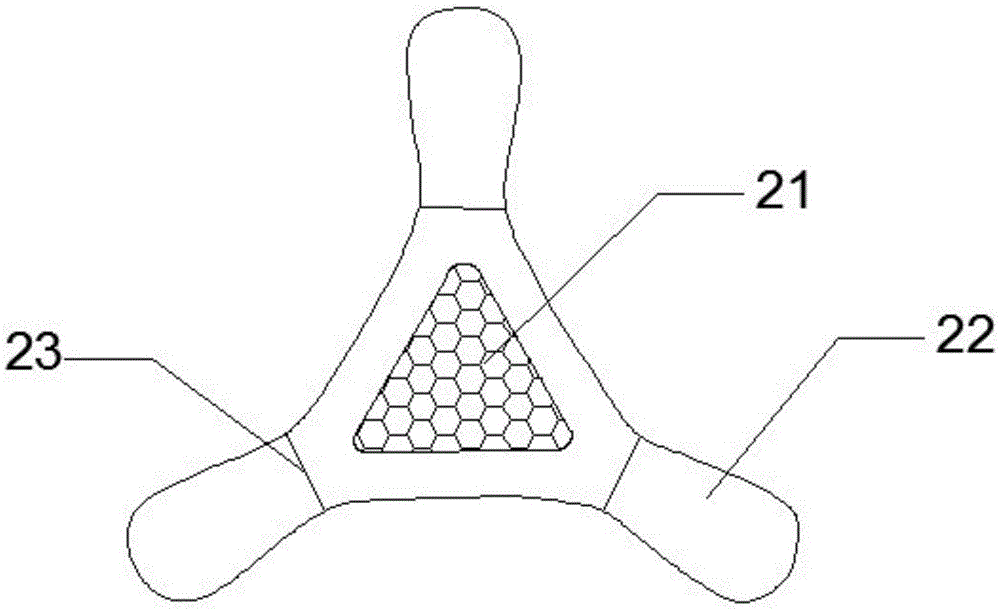

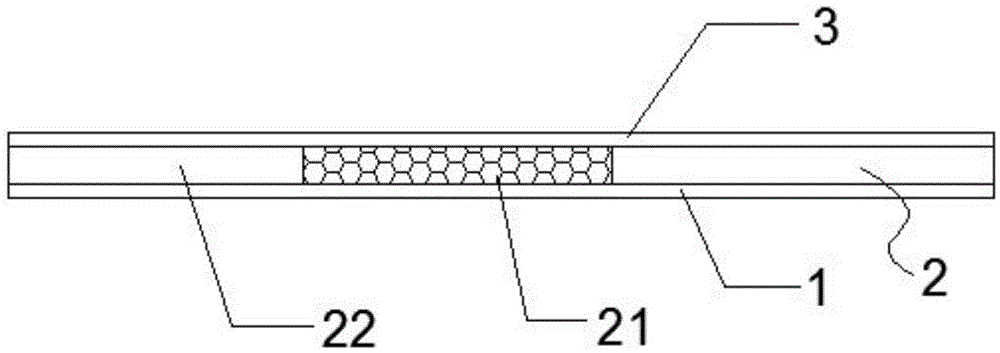

Image

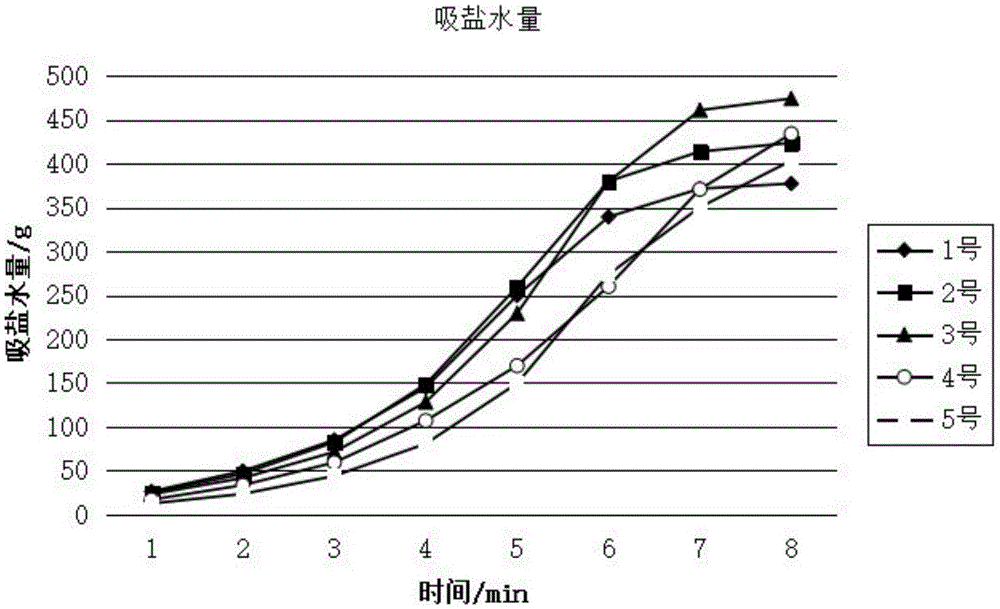

Examples

Embodiment 1

[0040] A hydrogel wound dressing made from:

[0041] 30g of water, 20g of gelling agent, 5g of crosslinking agent (magnesium alanine), 1g of disodium edetate, 0.01g of pH regulator (citric acid), 20g of thickener (xanthan gum), humectant (glycerol) 5g and antibacterial agent (pentylene glycol) 5g. The gelling agent is a mixture of polyacrylic acid, carbomer, polyacrylic acid amine, sodium polyacrylate, acrylic acid polymer containing carboxylic acid group and polymethacrylic acid.

[0042] Its preparation method comprises the following steps:

[0043] (1) adjusting pH for the first time: taking water according to the proportioning ratio, adding a pH regulator to the water until the pH of the water is 8, forming alkaline water;

[0044] (2) Mixing for the first time: add gelling agent and thickener to alkaline water, heat to 95°C, keep at 95°C and stir until the gelling agent and thickener are completely dissolved and evenly dispersed to form a premix;

[0045] (3) Second mi...

Embodiment 2

[0050] The invention provides a hydrogel wound dressing, which is made of the following raw materials:

[0051] Water 90g, gelling agent 1g, crosslinking agent (iron valine) 0.1g, tetrasodium 0.01g, pH regulator 3g, thickener (carrageenan) 1g, humectant (carboxymethyl chitosan) 0.5 g and bacteriostatic agent (chitin) 0.5g. The gelling agent is a mixture of polyacrylic acid, carbomer, polyacrylic acid amine, sodium polyacrylate, polymer containing acrylate, polymethacrylic acid and partially neutralized polyacrylic acid.

[0052] Its preparation method comprises the following steps:

[0053] (1) adjusting pH for the first time: taking water according to the proportioning ratio, adding a pH regulator to the water until the pH of the water is 10, forming alkaline water;

[0054] (2) Mixing for the first time: add gelling agent and thickener to alkaline water, heat to 85°C, keep the temperature and stir until the gelling agent and thickener are completely dissolved and evenly di...

Embodiment 3

[0060] A hydrogel wound dressing made from:

[0061] 50g of water, 3g of gelling agent, 0.5g of cross-linking agent (aluminum glycinate), 0.5g of disodium edetate, 0.5g of tetrasodium, 0.05g of pH regulator (lycitric acid), thickener (gellan gum ) 10g, humectant (β-glucan) 2g and antibacterial agent (zinc chloride) 1g.

[0062] The structural formula of aluminum glycinate is as follows:

[0063]

[0064] The use of aluminum glycinate can not only improve the product process, make the production operation more simple and easy to operate, and make the process more controllable; but also increase the tensile strength of the hydrogel wound dressing colloid, and the use effect is better. The general PVA colloid is too strong. However, the tensile strength of the traditional hydrogel is too small, and the crosslinking agent can control the tensile strength of the colloid within a certain range.

[0065] Its preparation method comprises the following steps:

[0066] (1) adjust ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com