Parallel seam welding alloy cover plate for integrated circuit packaging and preparation method thereof

An integrated circuit and parallel seam welding technology, which is applied in the direction of circuits, electrical components, and electrical solid devices, can solve the hidden dangers of circuit application reliability and the difficulty of avoiding iron element exposure, etc., and achieve good salt spray corrosion resistance and meet The effect of application requirements in salt spray environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with specific drawings.

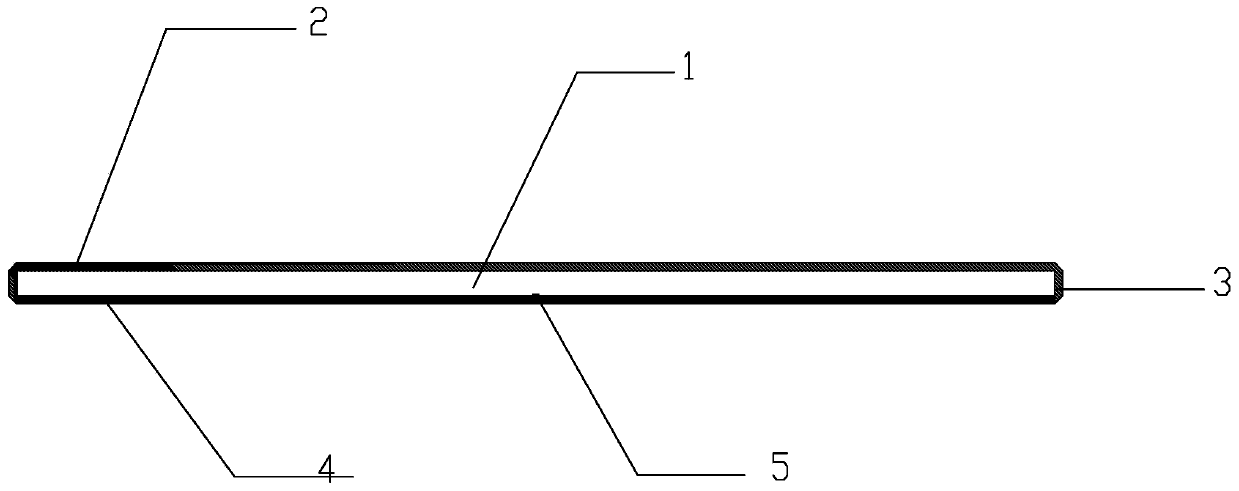

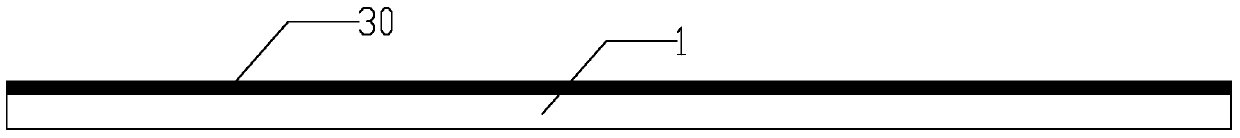

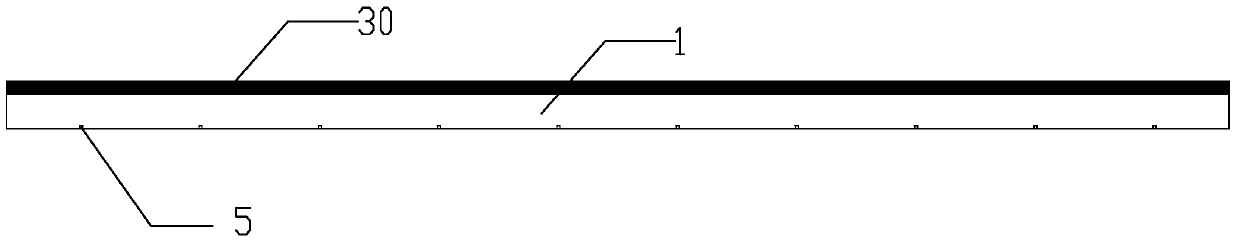

[0039] Such as figure 1 As shown, the parallel seam welding alloy cover plate for integrated circuit packaging of the present invention includes an alloy cover plate body 1, and the outer surface of the front surface of the alloy cover plate body 1 is formed by an electroplating process to form a first electroplated nickel layer 2. The alloy cover plate The side outer surface of the plate body 1 is formed by an electroplating process to form a second electroplating nickel layer 3, and the reverse outer surface of the alloy cover plate body 1 is formed by an electroless plating process to form an electroless nickel plating layer 4, thereby forming a structure with different coating layers on the front and back surfaces. The alloy cover plate structure; the reverse side of the alloy cover plate body 1 is a welding surface, and a dot or other shape mark 5 is formed at the middle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com