Single eccentric butterfly valve with double sealing pairs

An eccentric butterfly valve and double-sealing technology, which is applied in the direction of lifting valves, valve devices, combustion engines, etc., can solve the problems of unbalanced torque of the shaft of the valve stem, the butterfly valve cannot be applied to high-pressure working conditions, and the valve is difficult to open and close, etc., to achieve good sealing effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

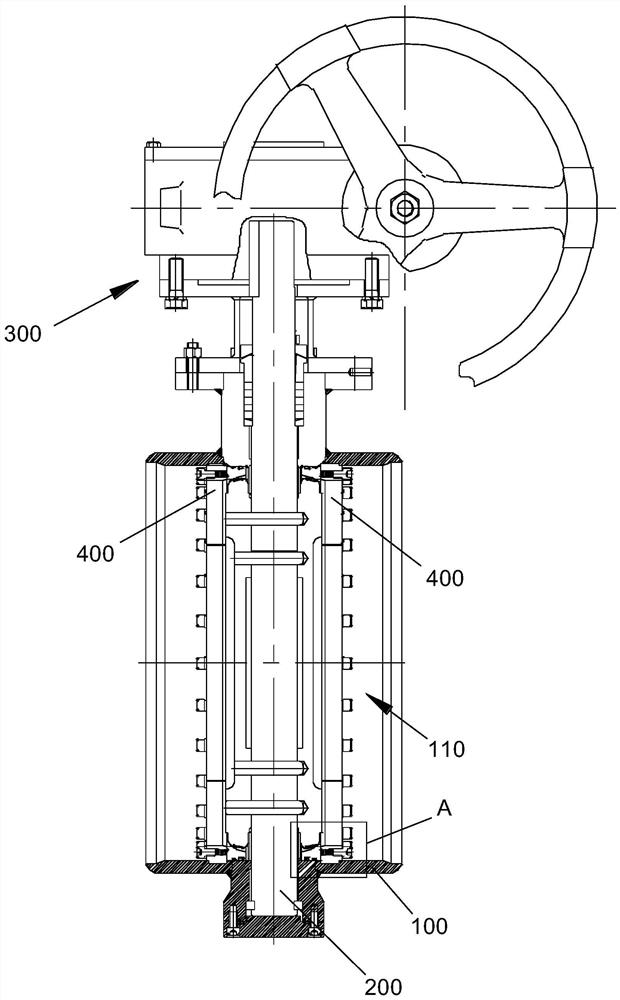

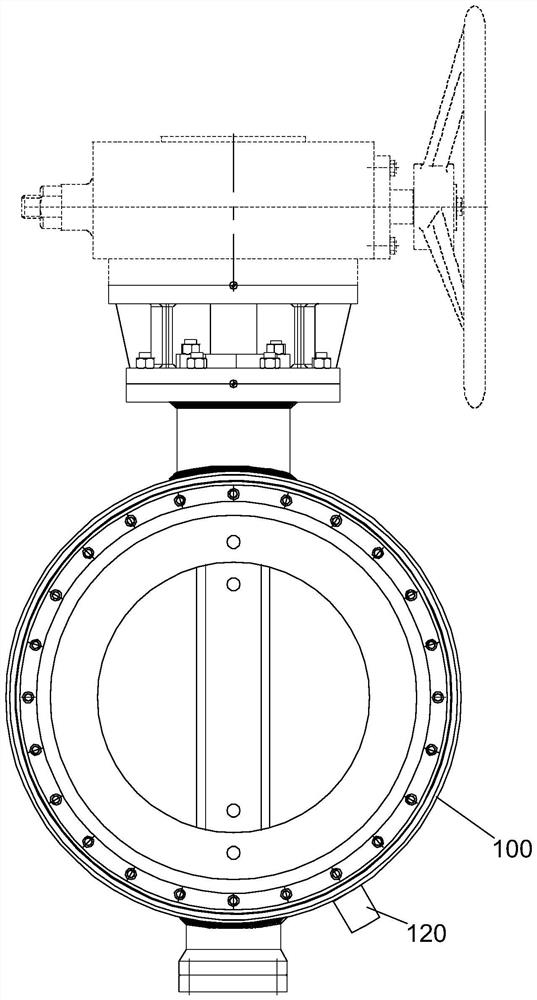

[0041] This embodiment provides a double-sealed pair single-eccentric butterfly valve, refer to figure 1 and figure 2 As shown, it includes a valve body 100, a valve stem 200 and an actuator 300, the valve body 100 is provided with a valve cavity 110, the actuator 300 is arranged on the valve body 100, the power input end of the valve stem 200 and the output of the actuator 300 The end is connected, and the power output end extends into the valve cavity 110 .

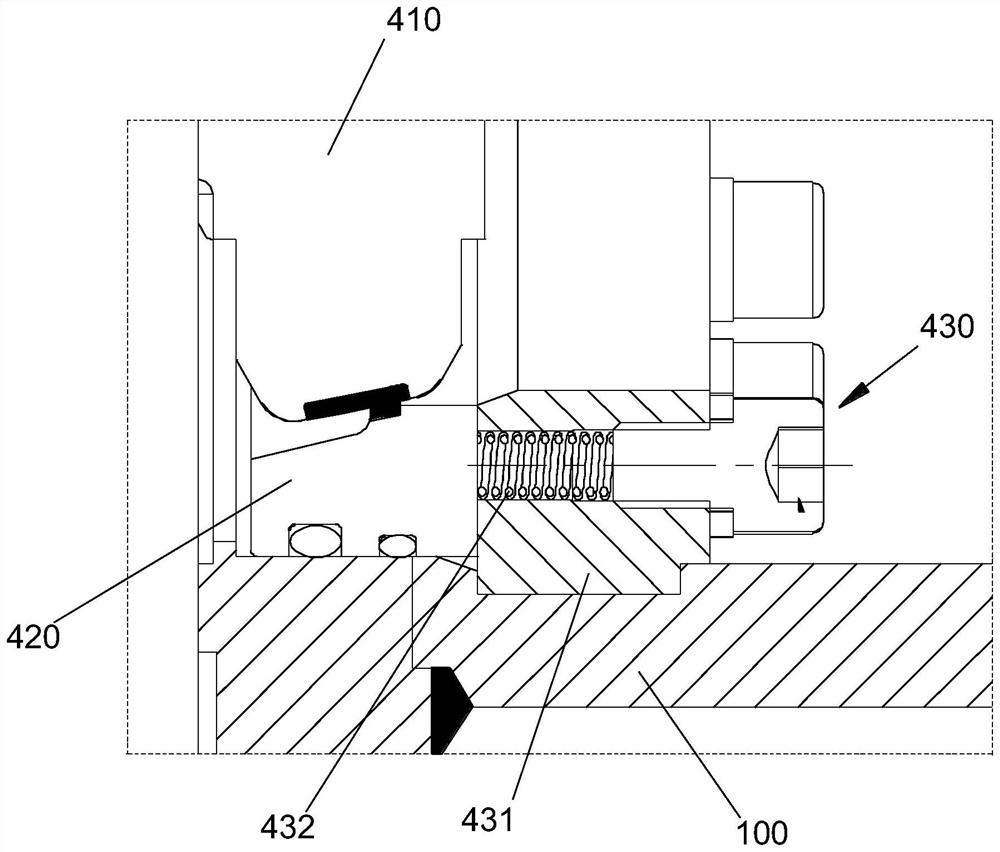

[0042] The double-sealed pair single eccentric butterfly valve further includes two groups of sealing mechanisms 400, the two groups of sealing mechanisms 400 are respectively arranged on two opposite sides of the valve stem 200, and each sealing mechanism 400 includes a butterfly plate 410, a valve seat 420 and a limit assembly 430; The butterfly plate 410 is fixedly connected with the valve stem 200 , the valve seat 420 is slidably arranged in the valve cavity 110 , the limiting component 430 includes a blocking rin...

Embodiment 2

[0051] This embodiment relates to a double-sealing pair single-eccentric butterfly valve, which has substantially the same structure as the double-sealing pair single-eccentric butterfly valve described in the first embodiment. The difference lies in that, in this embodiment, refer to Figure 4 and Figure 5 As shown, it also includes a casing 510, a transmission unit 520 and a buffer mechanism 530, the casing 510 is arranged on the valve body 100, the transmission unit 520 and the buffer mechanism 530 are arranged in the casing 510; the power output end of the valve stem 200 passes through Out of the valve body 100 and extending into the housing 510, the transmission unit 520 is arranged between the power output end and the buffer mechanism 530; when the valve stem 200 drives the butterfly plate 410 to rotate in the direction of being combined with the corresponding valve seat 420, the buffer mechanism 530 The transmission unit 520 provides a buffer force for the rotation of ...

Embodiment 3

[0068] This embodiment relates to a double-sealing pair single-eccentric butterfly valve, which is substantially the same in structure as the double-sealing pair single-eccentric butterfly valve provided in the second embodiment. The difference is that in this embodiment, refer to Figure 5 As shown, the rack 522 is provided with an actuating portion 5222, the housing 510 is provided with a sounding assembly 700, and the sounding assembly 700 is located on the sliding path of the actuating portion 5222; when the butterfly plate 410 is rotated to be combined with the corresponding valve seat 420, The actuating part 5222 acts on the sounding element to make the sounding element emit sound.

[0069] When closing the butterfly valve, even though the butterfly plate 410 may have been rotated in place, the operator will continue to apply torque to the butterfly plate 410 because the operator does not realize that the butterfly plate 410 has been rotated in place in time, which may ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com