A dry etching device and method

A technology of dry etching device and etching chamber, which is applied in the manufacture of discharge tubes, electrical components, semiconductors/solid-state devices, etc., and can solve the problems of standing waves on electrode surfaces, inability to etch uniformly over a large area, and uneven etching rates, etc. problems, to achieve the effect of improving uniformity, increasing etching speed, and uniform etching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

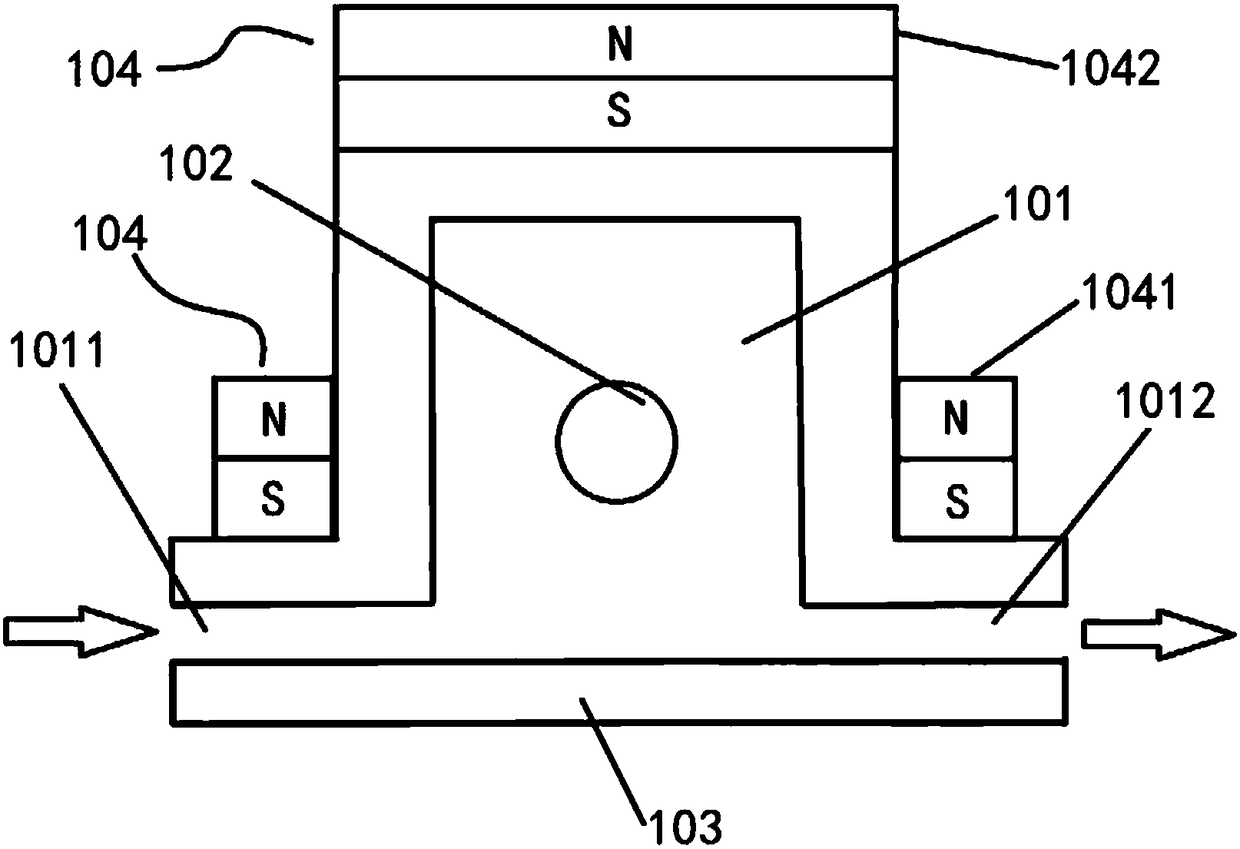

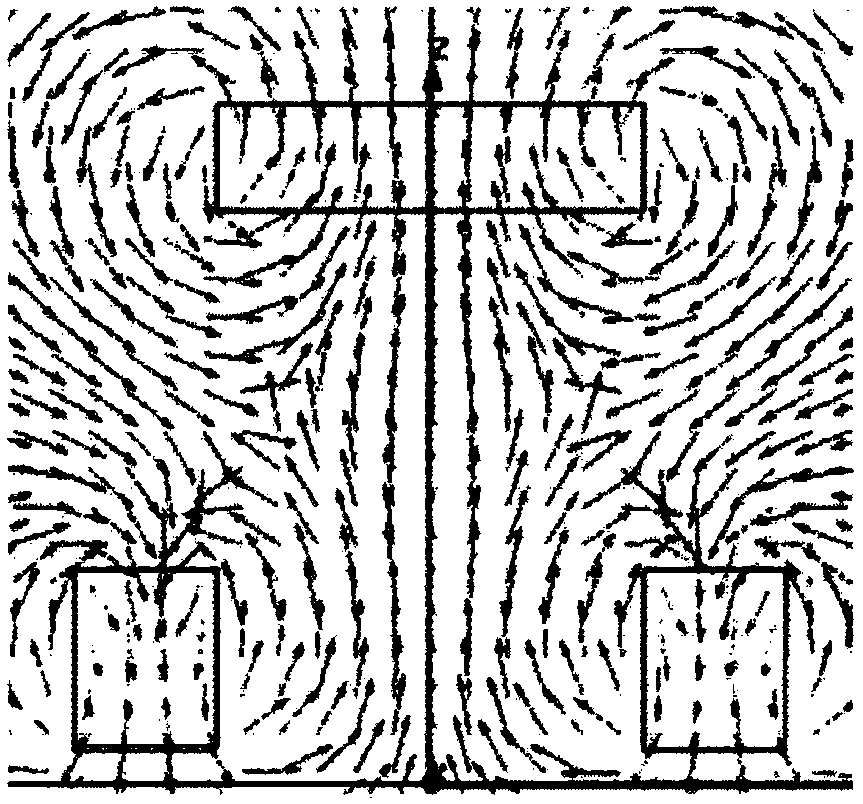

[0029] The present invention firstly provides a dry etching device, such as figure 1 As shown, it includes a vacuum etching chamber 101, a coaxial circular waveguide 102, a carrier for carrying a substrate to be etched, and a coaxial microwave source connected to the coaxial circular waveguide; wherein:

[0030] The coaxial circular waveguide 102 is arranged inside the vacuum etching chamber 101, and is used to transmit electromagnetic waves generated by the coaxial microwave source to excite plasma, so that the plasma etches the to-be-treated area under the coaxial circular waveguide 102. Etch the substrate.

[0031] It can be seen from the above that the dry etching device provided by the present invention uses a coaxial microwave source to generate e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com