Broccoli polypeptide extract as well as preparation method and application thereof

A technology of broccoli and extract, applied in the field of broccoli polypeptide extract, can solve the problems such as few literature reports, and achieve the effects of simple equipment, high yield and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

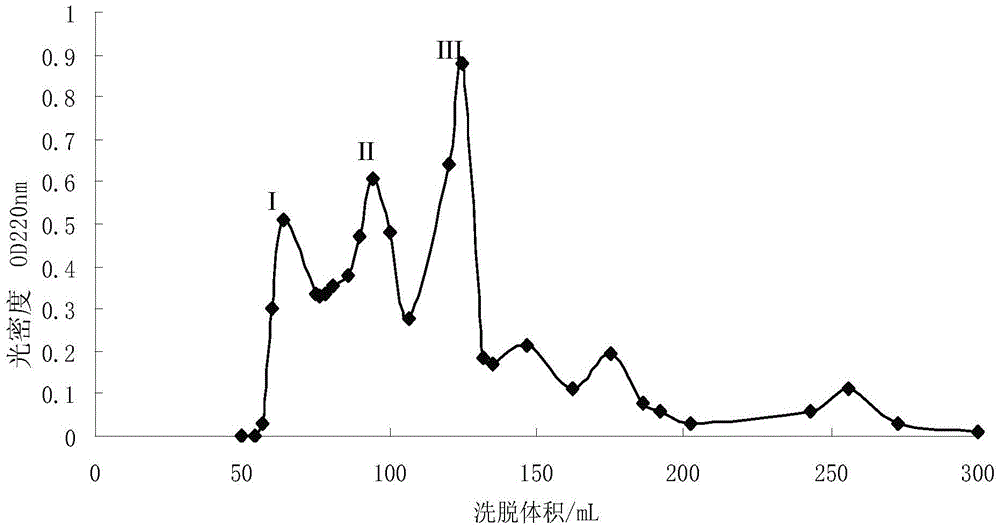

Image

Examples

Embodiment 1

[0035] The preparation of embodiment 1 broccoli polypeptide extract

[0036] (1) Take broccoli stems and leaves, first carry out enzymatic hydrolysis pretreatment, use pectinase (Novozymes (China) Biotechnology Co., Ltd.) and cellulase (Novozymes (China) Biotechnology Co., Ltd.) Compound at a ratio of 1:1 to form a compound enzyme, then add water to form an enzymolysis solution, the ratio of the mass of the compound enzyme to the volume of the enzymolysis solution is 2.5g: 100mL, that is, the total amount of enzyme added is 2.5% (w / v), Put the broccoli stems and leaves into the enzymolysis solution for enzymolysis, the enzymolysis temperature is 60°C, the enzymolysis time is 3h, then the pH is adjusted to 8-8.5 for alkaline extraction, the alkaline extraction time is 1.5h, and then centrifuged at 5000r / min for 15min to adjust the The pH of the supernatant was at the isoelectric point pI to precipitate protein, discard the supernatant, wash the precipitate three times with wate...

Embodiment 2

[0039] The preparation of embodiment 2 broccoli polypeptide extract

[0040] (1) Take broccoli stems and leaves, first carry out enzymatic hydrolysis pretreatment, use pectinase (Novozymes (China) Biotechnology Co., Ltd.) and cellulase (Novozymes (China) Biotechnology Co., Ltd.) Compound at a ratio of 0.5:1 to form a compound enzyme, then add water to form an enzymolysis solution, the ratio of the mass of the compound enzyme to the volume of the enzymolysis solution is 1g: 100mL, that is, the total amount of enzyme added is 1% (w / v), and the Put broccoli stems and leaves into enzymolysis solution for enzymolysis, enzymolysis temperature 50℃, enzymolysis time 4h, then adjust pH 9.0 for alkaline extraction, alkaline extraction time 1h, then centrifuge at 4000r / min for 10min, adjust the supernatant The pH is at the isoelectric point pI to precipitate the protein, discard the supernatant, wash the precipitate three times with water, adjust the pH to 7.0, and dry to obtain broccoli...

Embodiment 3

[0043] The preparation of embodiment 3 broccoli polypeptide extract

[0044] (1) Take broccoli stems and leaves, first carry out enzymatic hydrolysis pretreatment, use pectinase (Novozymes (China) Biotechnology Co., Ltd.) and cellulase (Novozymes (China) Biotechnology Co., Ltd.) Compound at a ratio of 1.5:1 to form a compound enzyme, then add water to form an enzymolysis solution, the ratio of the mass of the compound enzyme to the volume of the enzymolysis solution is 5g: 100mL, that is, the total amount of enzyme added is 5% (w / v), and the Put broccoli stems and leaves into enzymolysis solution for enzymolysis, enzymolysis temperature 70°C, enzymolysis time 2h, then adjust pH 7.5 for alkaline extraction, alkaline extraction time 2h, then centrifuge at 6000r / min for 20min, adjust the supernatant The pH is at the isoelectric point pI to precipitate the protein, discard the supernatant, wash the precipitate three times with water, adjust the pH to 7.0, and dry to obtain broccol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com