Method for preparing energy source gas from chloride-free plastics and simultaneously performing harmless treatment on chromium slag

A technology of energy gas and chromium slag, which is applied to the removal of solid waste, products, educts, etc., can solve the problems of non-continuous utilization, expensive catalyst, equipment blockage, etc., to avoid device control of air pressure, improve the quality of fuel products, and save energy. energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

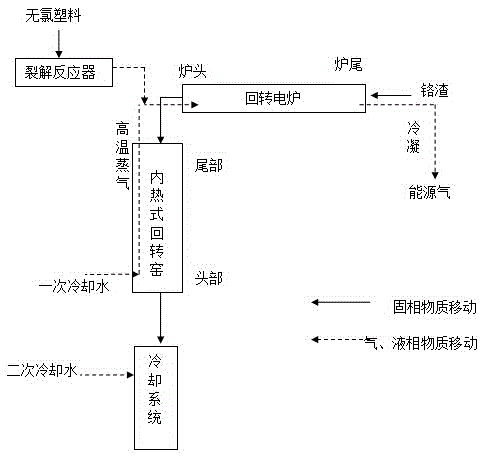

[0026] 1. After the chromium slag is ground to <2mm, it is transported to the tail of the rotary electric furnace through the screw feeder, and finally transported to the furnace head. Heating by an electric furnace keeps the temperature of the chromium slag at the furnace head stable at 800-1000°C. After being discharged from the furnace head, the chromium slag enters the internal heating rotary kiln head, and then is transported to the kiln tail;

[0027] 2. The chlorine-free plastic is cracked at 500-600°C, and the cracked gas is then sent to the burner head of the rotary electric furnace, where it is mixed with high-temperature steam and chromium slag outside the burner head; the mixed gas of high-temperature steam and plastic cracking gas is mixed with chromium slag in the rotary electric furnace Reverse operation, catalytic cracking reaction occurs in the process, after the tail of the rotary electric furnace is discharged, high-quality energy gas is obtained through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com