Non-magnetic position detection sensor

A sensor and magnetic frame technology, applied in the field of non-magnetic position detection sensors, can solve the problems of affecting the accuracy and sensitivity of the action, high cost, easy to drop powder, etc., so as to improve the working stability and service life, improve the sensitivity and accuracy The effect of avoiding metal fatigue and impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

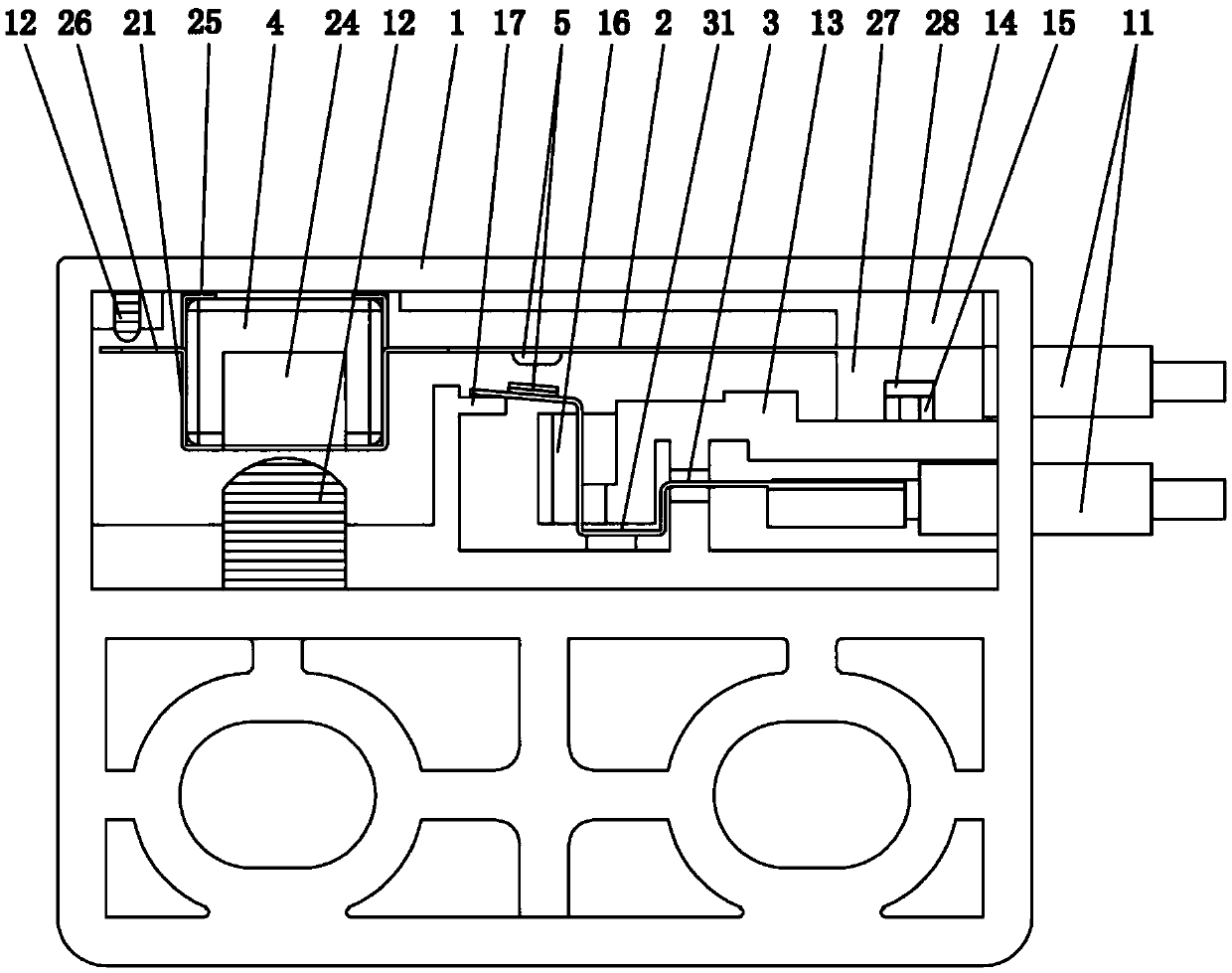

[0020] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

[0021] Such as figure 1 As shown, a non-magnetic position detection sensor according to the present invention includes a hollow plastic box 1, an action piece 2 is arranged horizontally in the inner cavity of the plastic box 1, and one end of the action piece 2 is fixed to the plastic box 1 connection, the action piece 2 is flexible and the other end can move freely up and down, the action piece 2 is provided with a silver contact 5 and a conductive sheet 3 is provided under the silver contact 5 to be on-off with it, and the plastic box 1 On the side wall, there are inlet and outlet leads 11 that are electrically connected to the action piece 2 and the conductive piece 3 respectively; the plastic box 1 is provided with a magnetizable body 4, and the magnetizable body 4 is connected to the other end of the action piece 2 to form an int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com