Raw Pu'er tea grade and quality evaluation method

A technology for quality evaluation and Pu'er tea, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of low specificity of objective inspection items, achieve objective and credible evaluation results, save testing costs, and be convenient and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

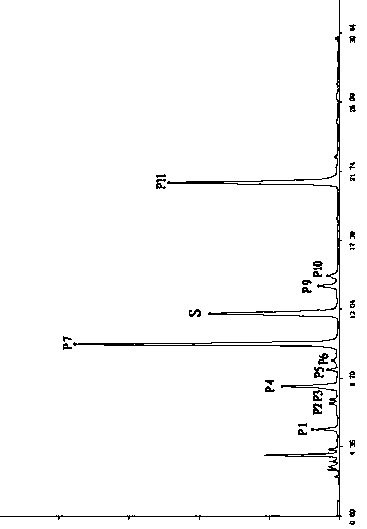

Embodiment 1

[0054] Take raw Pu-erh tea raw materials and pulverize them, take 3 grams of powder passed through a 40-mesh sieve, add 12 times the amount of methanol, extract in a water bath at 70°C for 10 minutes, extract twice, centrifuge, combine the supernatant and evaporate in a water bath at 80°C After drying, the residue was diluted to 10ml with methanol to obtain the test solution. Take an appropriate amount of epigallocatechin gallate reference substance, weigh it accurately, add methanol to prepare a solution containing 0.5 mg per 1 ml as the reference component solution. Octadecyl bonded silica gel is used as filler (C18 reverse-phase chromatographic column); the mobile phase is divided into two parts A and B, and gradient elution is carried out according to the time and volume ratio specified in Table 7; the detection wavelength is 245nm; The column temperature is 35°C; the flow rate is 1ml / min. The number of theoretical plates should not be less than 3000 based on the calculat...

Embodiment 2

[0059] Take puer tea raw tea Xiaotuocha and grind it, take 5 grams of powder passed through a 40-mesh sieve, add 20 times the amount of acetone and extract it in a water bath at 80°C for 15 minutes, extract twice, centrifuge, and combine the supernatant on a water bath at 80°C Evaporate to dryness, and dilute the residue to 10ml with methanol to obtain the test solution. Take an appropriate amount of epigallocatechin gallate reference substance, weigh it accurately, add methanol to prepare a solution containing 0.5 mg per 1 ml as the reference component solution. Octadecyl bonded silica gel is used as filler (C18 reverse-phase chromatographic column); the mobile phase is divided into two parts A and B, and gradient elution is carried out according to the time and volume ratio specified in Table 8; the detection wavelength is 360nm; The column temperature is 35°C; the flow rate is 1ml / min. The number of theoretical plates should not be less than 3000 based on the calculation o...

Embodiment 3

[0064] Take puerh tea raw tea cake and pulverize it, take 4 grams of powder passed through a 40-mesh sieve, add 15 times the amount of 95% ethanol aqueous solution, extract in a water bath at 75°C for 12 minutes, extract twice, centrifuge, and combine the supernatant at 80°C Evaporate to dryness on a water bath at ℃, and dilute the residue to 10ml with methanol to obtain the test solution. Take an appropriate amount of epigallocatechin gallate reference substance, weigh it accurately, add methanol to prepare a solution containing 0.5 mg per 1 ml as the reference component solution. Octadecyl bonded silica gel is used as filler (C18 reversed-phase column); the mobile phase is divided into two parts, A and B, A is an acetonitrile solution containing 10% water and 2% acetic acid, B is a solution containing 10% acetonitrile and 2% acetic acid aqueous solution, carry out gradient elution according to the specified time and volume ratio in Table 9; the detection wavelength is 250nm;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com