Control method of combined heat recovery system of water source heat pump and plate heat exchanger

A technology of plate heat exchangers and water source heat pumps, applied in heat recovery systems, fluid heaters, cleaning heat transfer devices, etc., can solve problems such as large temperature difference changes, large temperature difference water discharge, etc., to prolong service life and solve seasonal problems The effect of temperature difference change and stable working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

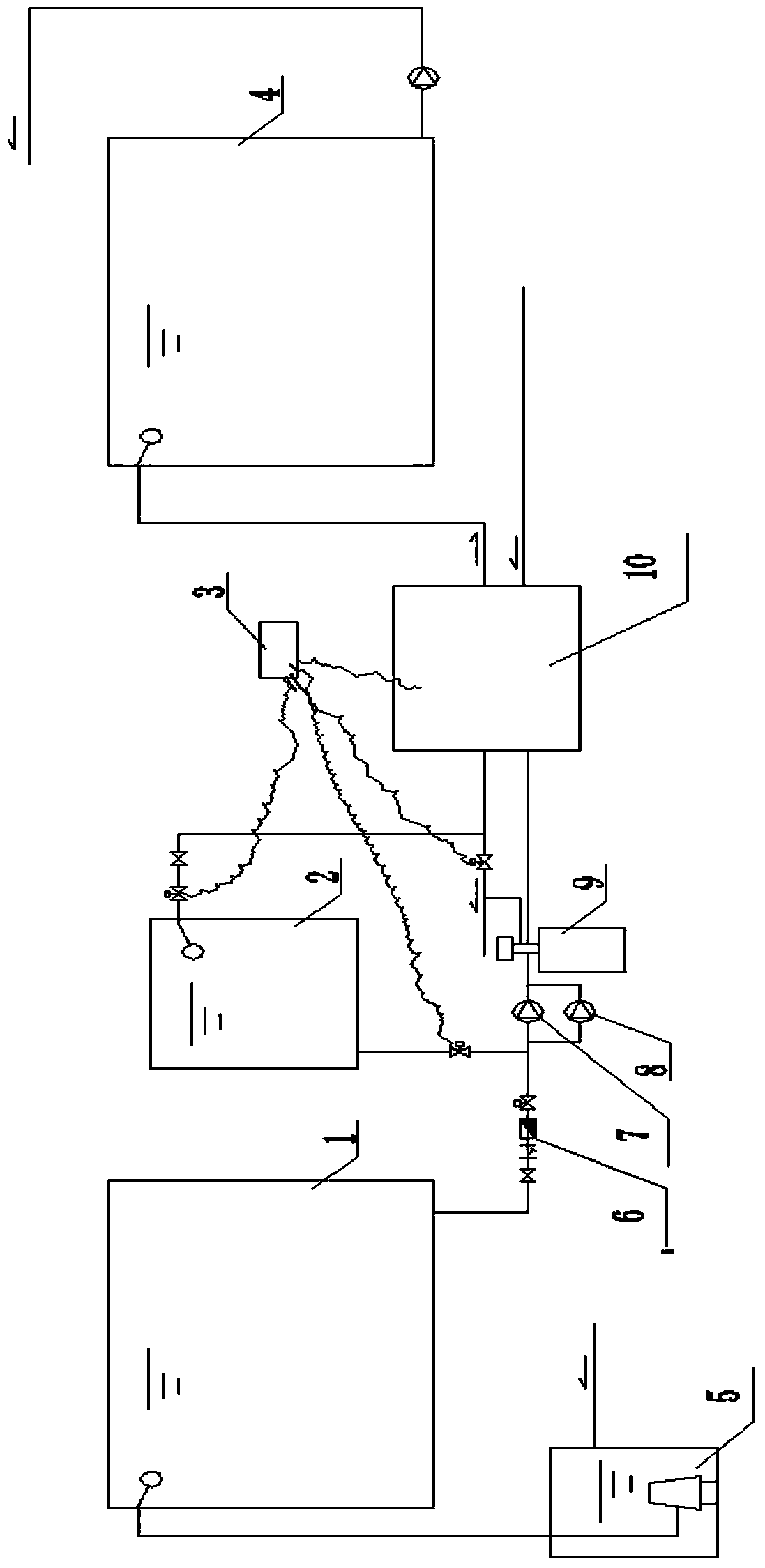

[0035] Such as Figure 1-3 As shown, a combined heat recovery system of a water source heat pump and a plate heat exchanger, the whole system includes a waste water collection tank 1, a sand tank filter 9, a heat exchange unit unit 10, a hot water tank 4, an electric control system 3 and a backwash water tank 2. The sand tank filter 9 is respectively connected to the waste water collection tank 1 and the backwash water tank 2 through pipelines, and the heat source side of the heat exchange unit 10 is respectively connected to the drain pipe and the sand tank filter 9, and the use side is respectively Connect running water pipe and hot water tank 4, on the pipeline between described waste water collecting tank 1 and sand tank filter 9, flow meter 6 and pressurized water pump group are also installed, and described pressurized water pump group is composed of pressurized water pump A7 and pressurized water pump B8 are connected in parallel;

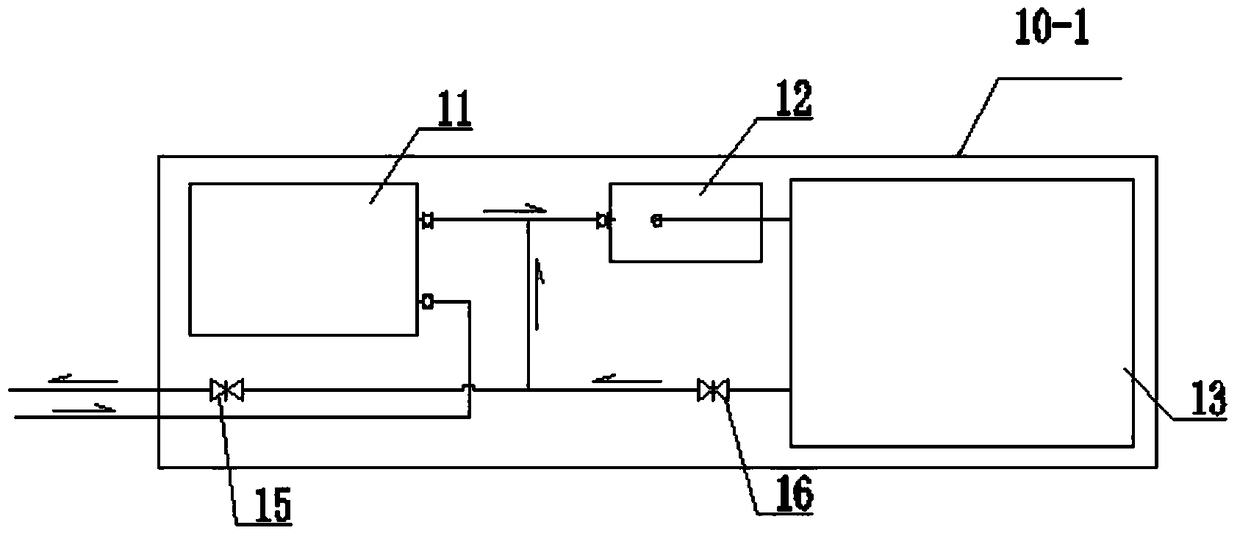

[0036] The heat exchange unit 10 inc...

Embodiment 2

[0040] Such as Figure 1-3 As shown, a control method for a combined heat recovery system of a water source heat pump and a plate heat exchanger includes the following steps:

[0041] A. Start the control process

[0042] A1, the submersible pump in the sump 5 is controlled by the liquid level of the sump 5 to start, and the waste water is transported to the waste water collection tank 1, and the electric control system 3 collects the water level and temperature signal of the waste water collection tank 1 in real time;

[0043] A2. All solenoid valves are closed when they are not working;

[0044]A3. Detect the water level of the waste water collection tank 1. When the water level is within the control value range, open the solenoid valve on the outlet pipe of the waste water collection tank 1, start the pressurized water pump A7 or pressurized water pump B8 in turn, and open the tap water inlet pipe at the same time. solenoid valve;

[0045] A4. Turn on the circulating wat...

Embodiment 3

[0056] Such as Figure 1-3 As shown, a combined heat recovery system of a water source heat pump and a plate heat exchanger, the whole system includes a waste water collection tank 1, a sand tank filter 9, a heat exchange unit unit 10, a hot water tank 4, an electric control system 3 and a backwash water tank 2. The sand tank filter 9 is respectively connected to the waste water collection tank 1 and the backwash water tank 2 through pipelines, and the heat source side of the heat exchange unit 10 is respectively connected to the drain pipe and the sand tank filter 9, and the use side is respectively Connect running water pipe and hot water tank 4, on the pipeline between described waste water collecting tank 1 and sand tank filter 9, flow meter 6 and pressurized water pump group are also installed, and described pressurized water pump group is composed of pressurized water pump A7 and pressurized water pump B8 are connected in parallel;

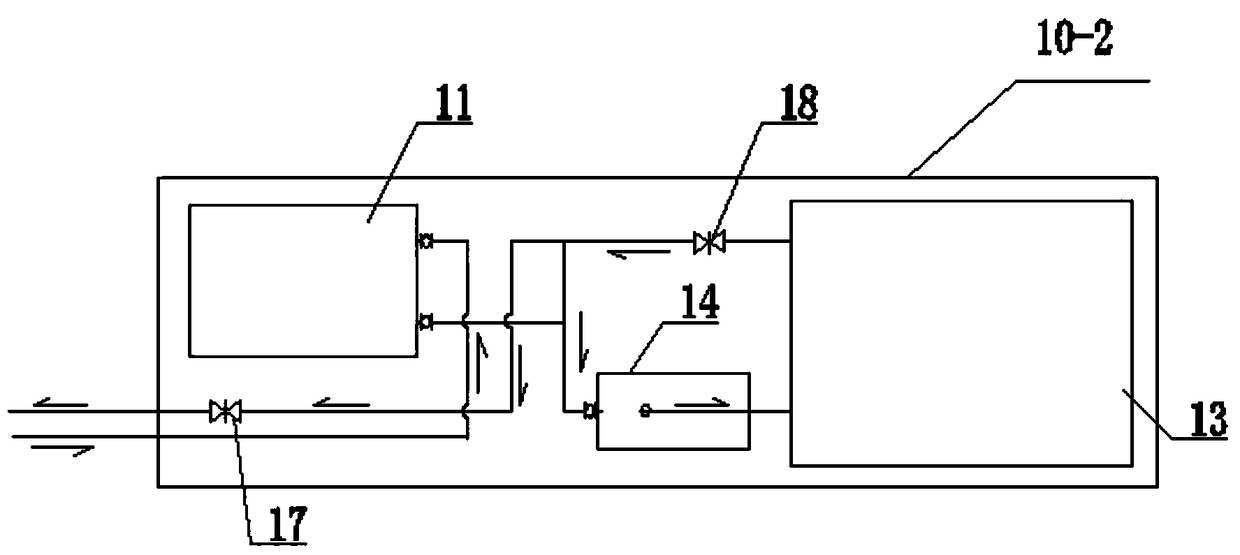

[0057] The heat exchange unit 10 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com