High-fluidity, scratch-resistant and low-temperature-folding-resistant ABS (acrylonitrile butadiene styrene)/TPU (thermoplastic polyurethane) alloy material and preparation method and application thereof

An alloy material and scratch-resistant technology, which is applied in the field of high-flow, scratch-resistant, low-temperature foldable ABS/TPU alloy materials and its preparation, and ABS composite modified materials, to achieve excellent processing performance, good fluidity, and scratch resistance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~14

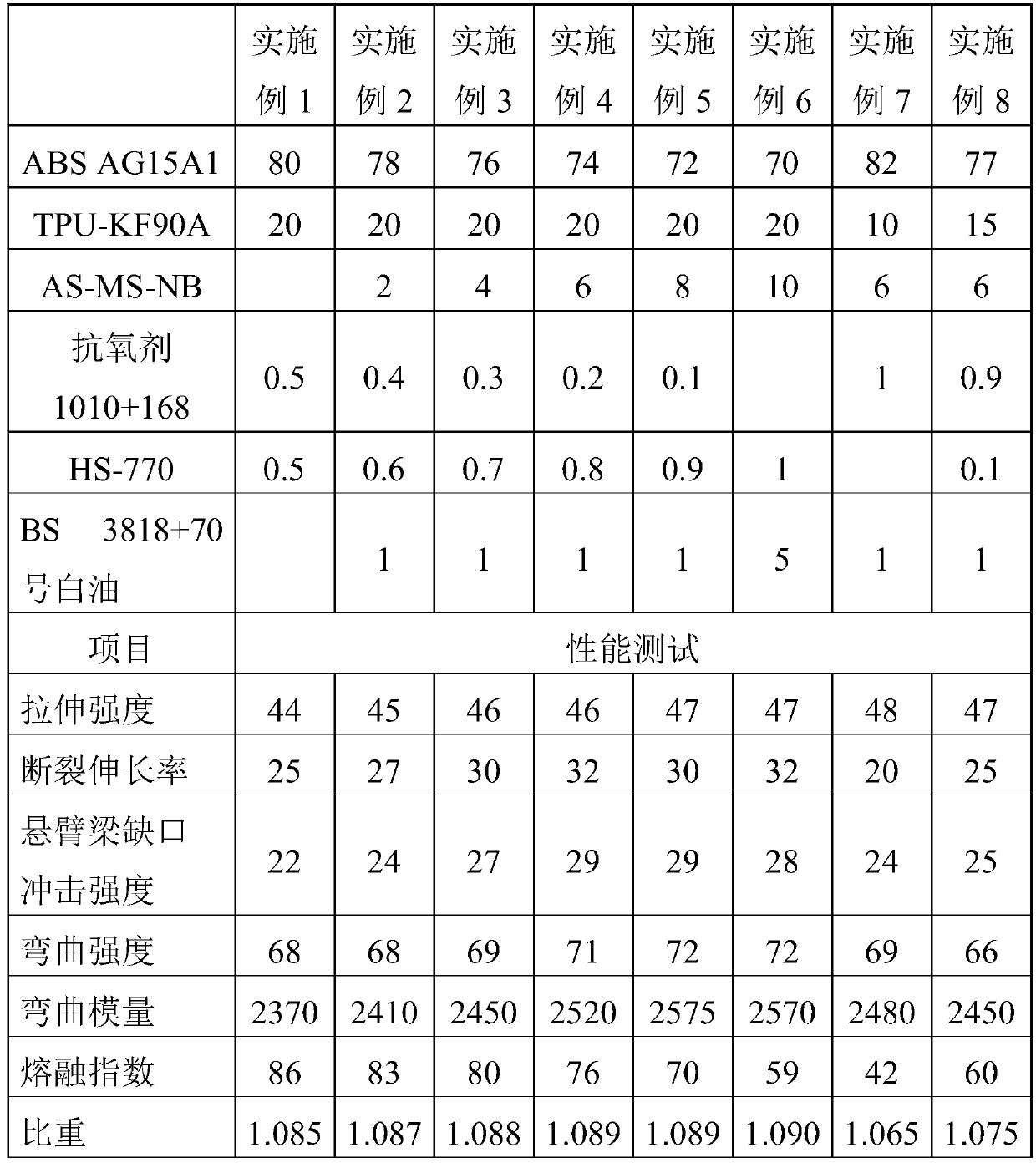

[0029] First, the components of Examples 1-14 and Comparative Examples 1-2 shown in Tables 2-3 were successively added to a high-speed mixer according to the proportioning ratio, and the ABS resin was dried at 85°C for 4 hours before mixing. , thermoplastic polyurethane TPU is dried at 100°C for 4 hours before mixing, and the speed of the high-speed mixer is set to 800rpm; then the above mixture is sent to a twin-screw extruder for mixing, extrusion, stranding, cooling, and pelletizing; among them, The length-to-diameter ratio of the twin-screw extruder is 40:1; the temperature of the screw barrel is set as follows: the temperature of the first zone is 80°C, the temperature of the second zone is 190°C, the temperature of the third zone is 200°C, the temperature of the fourth zone is 210°C, and the temperature of the fifth zone is 220°C , the temperature of the sixth zone is 220°C, the temperature of the seventh zone is 220°C, the temperature of the eighth zone is 220°C, the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com