Method for preparing hydrophobic melamine foam

A melamine and foam technology, applied in the coating and other directions, can solve the problems of poor thermal insulation and sound absorption, affecting the use value, easy to increase the density, etc., and achieve the effects of reducing water absorption, good elasticity and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

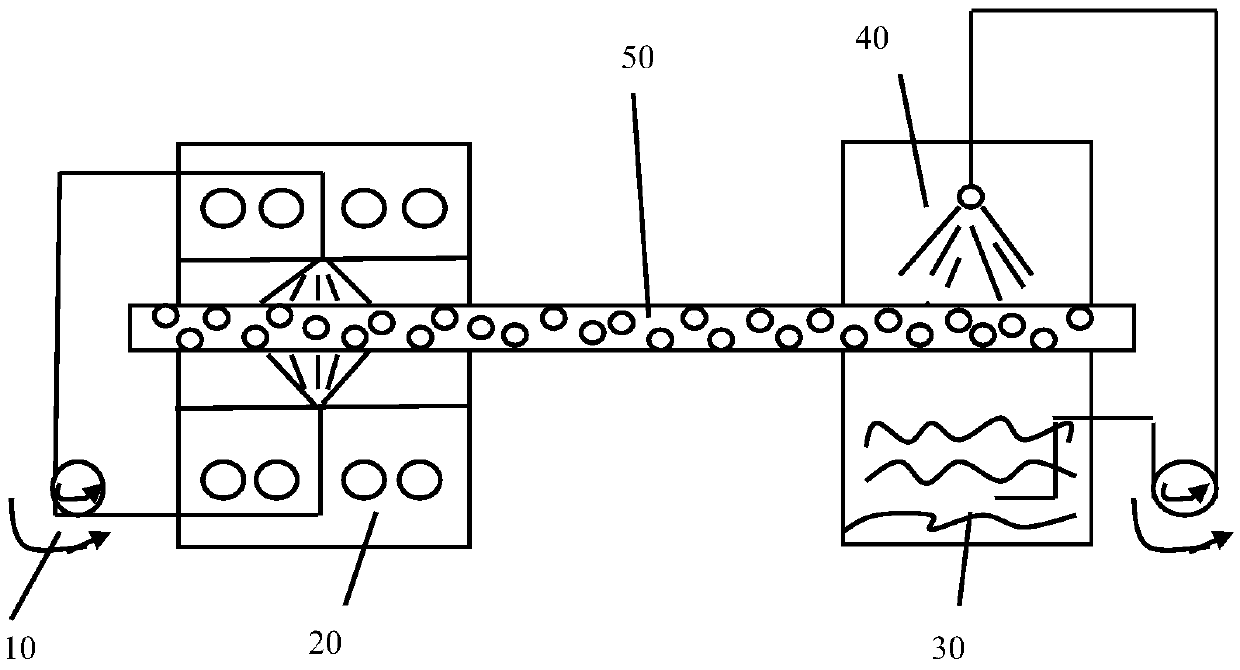

[0018] A kind of preparation method of water-repellent melamine foam, it is characterized in that comprising the following steps:

[0019] (1) Mix melamine and formaldehyde at a molar ratio of 1:2, then react at 80°C for 30 minutes to obtain a precondensate with a viscosity of 14000mPa.s, mix the precondensate with hardener, nonionic surfactant, foaming agent, The light stabilizer and deionized water are mixed to form a foaming liquid with a viscosity of 8000mPa.s. The foaming liquid is foamed at a temperature of 40~70°C formed by microwave radiation with a power of 20kw for 1 minute to form a foam body, and the foam body is heated at a temperature of 80°C. Curing for 7 minutes, and then annealing for 25 minutes under hot air conditions at 120°C to obtain a semi-finished melamine foam;

[0020] (2) Add 3 parts by mass of dimethyl silicone oil with a number average molecular weight of 5000 into 15 parts by mass of plasma water, hydrolyze for 3 hours, then add 4 parts by mass of...

Embodiment 2

[0025] A kind of preparation method of water-repellent melamine foam, it is characterized in that comprising the following steps:

[0026] (1) Mix melamine and formaldehyde at a molar ratio of 1:5, and then react at 95°C for 45 minutes to obtain a precondensate with a viscosity of 16000mPa.s. Mix the precondensate with hardener, nonionic surfactant, foaming agent, The light stabilizer and deionized water are mixed to form a foaming liquid with a viscosity of 11000mPa.s. The foaming liquid is foamed at a temperature of 70°C formed by microwave radiation with a power of 30kw for 3 minutes to form a foam, and the foam is cured at a temperature of 120°C for 25 minutes, and then annealed for 60 minutes under hot air conditions at 260°C to obtain a semi-finished melamine foam;

[0027] (2) Add 7 parts by mass of simethicone oil with a number average molecular weight of 16000 to 40 parts by mass of plasma water, hydrolyze for 6 hours, then add 13 parts by mass of silane coupling agen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com