Pharmaceutical grade bacitracin and preparing device thereof

A bacitracin and pharmaceutical-grade technology, applied in the field of pharmaceutical-grade bacitracin and its preparation device, can solve the problems of greater source influence, and achieve the effects of improving yield, improving purity, content, potency, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0050] Preparation Example 1: Preparation of Bacitracin Fermentation Broth

[0051] Take Bacillus subtilis, directly use soybean powder, starch, corn extract, molasses and inorganic salts as the medium, the inoculation amount is 5%, and the fermentation time is 30 hours; and the temperature at the initial stage of fermentation is 30°C, after 2-3 hours the temperature Increased to 37°C, the effective number of viable bacteria reached 1.1×10 9 CFU / g, that is.

preparation example 2

[0052] Preparation Example 2: Preparation of Bacitracin Fermentation Broth

[0053] The reference application publication number is the Chinese patent preparation of CN103232959A, and its preparation process includes: (1) primary seed culture: after bacillus licheniformis is activated on the beef extract peptone slant medium for 20 hours, transfer to the shake flask in the seed medium Cultivate for 16 hours, as seed culture liquid; (2) liquid state fermentation proliferating culture: transfer the first-level seed culture liquid to the inoculum size of 7% of the fermentation medium volume in the liquid state fermentation medium, the culture temperature is 35 ℃, cultivate After 20 hours, the number of effective viable bacteria reached 5.0×10 9 CFU / g, that is.

Embodiment 1

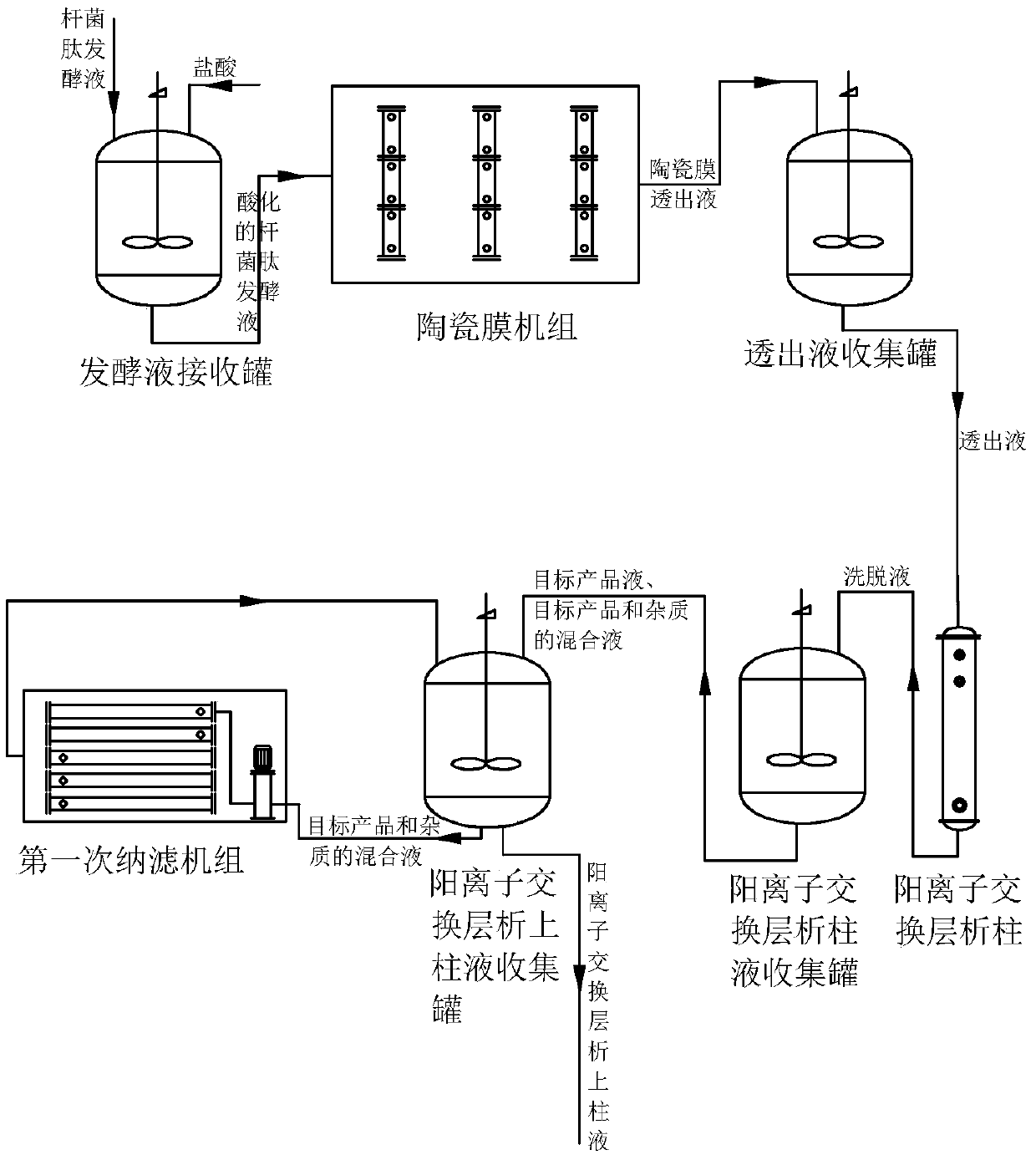

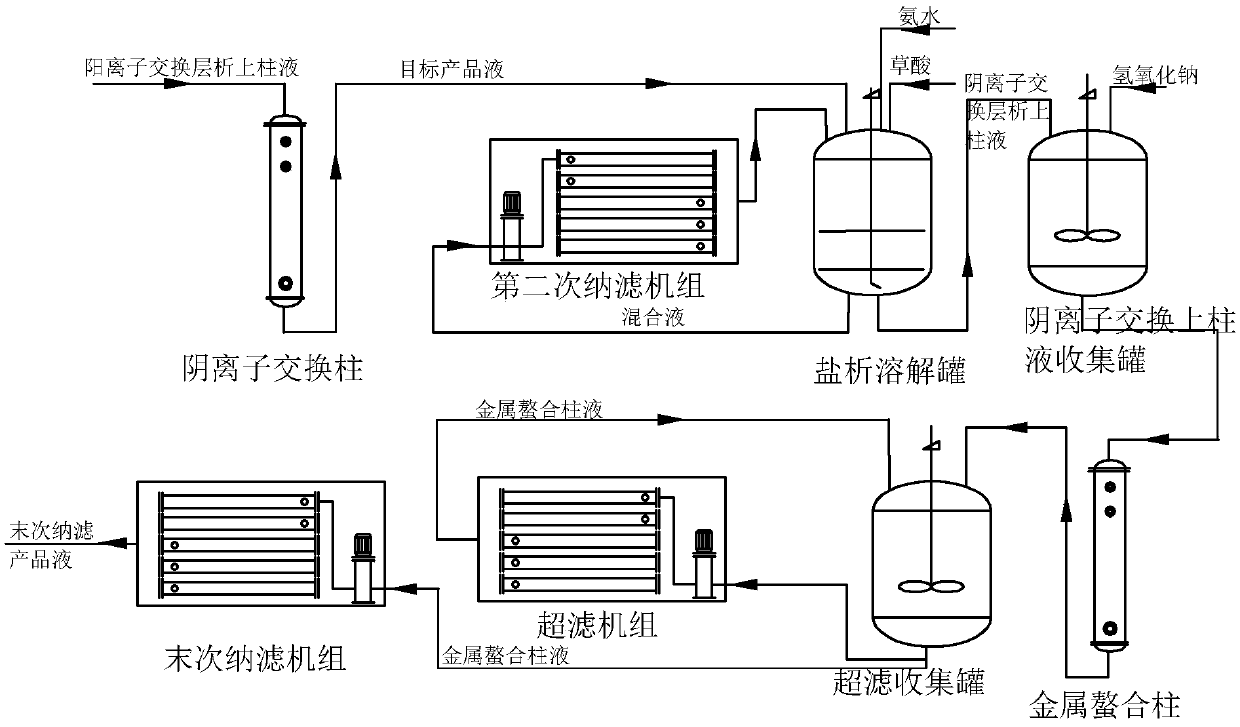

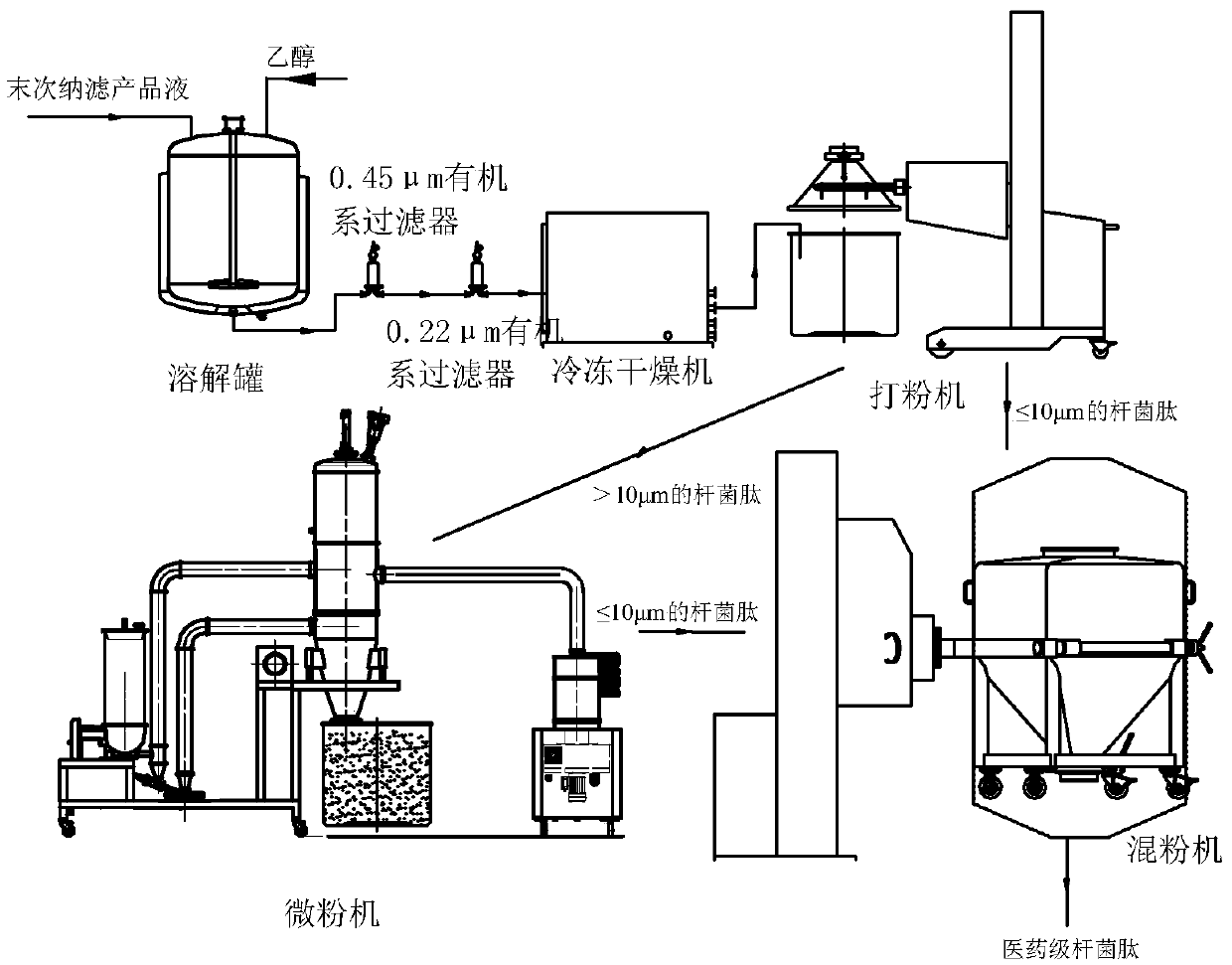

[0055] like figure 1 Shown, a kind of pharmaceutical grade bacitracin, its preparation method comprises the steps:

[0056] S1, get the bacitracin fermentation broth prepared in Preparation Example 1 (its effective viable count is 1.1×10 9 CFU / g) in the fermentation broth receiving tank, add 0.05M hydrochloric acid to acidify to pH 5.0-5.5; after stirring and mixing, transport the acidified bacitracin fermentation broth to the ceramic membrane unit (the material is activated alumina , the pore size of the ceramic membrane is 0.1-1.0 μm) to filter, and the ceramic membrane permeate is collected into the permeate collection tank through the pipeline;

[0057] S2, the dialyzate in the dialyzate collection tank enters the cation exchange chromatography column (the cation exchange chromatography column is BPG100 / 500, and the column filler is CaptoSpimpres) through the pipeline, and it passes through the NaCl aqueous solution of 0.1-2.5M and NaAc-HAc buffer solution with pH=3.0-5....

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com