Method for purifying lithium sulfate crude ore

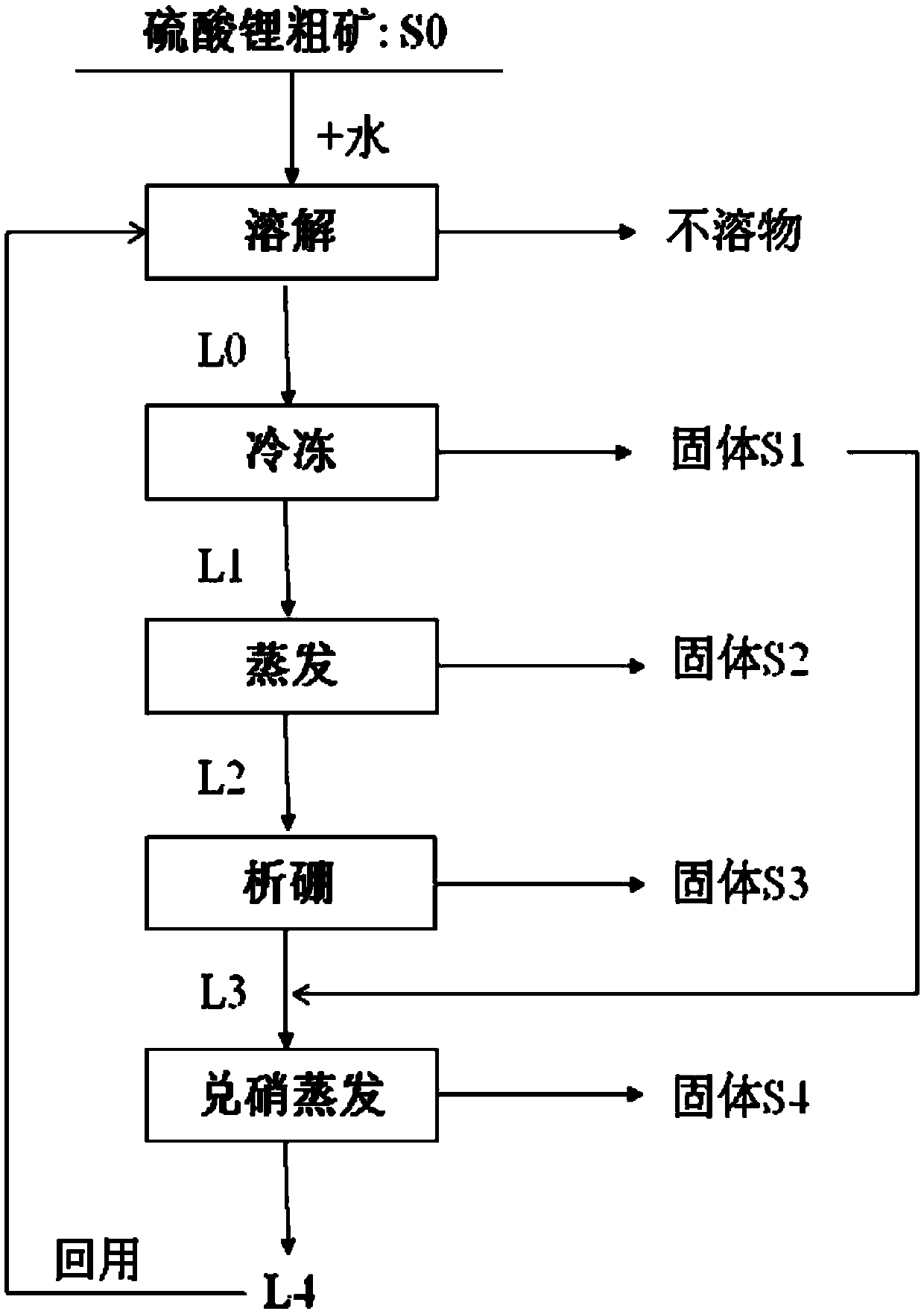

A refining method and technology of lithium sulfate, applied in the direction of lithium sulfate/sulfite, borate, alkali metal sulfite/sulfite, etc., can solve the problem of long process route, poor purity and yield of lithium sulfate products Ideal and other issues, to achieve the effect of simple process route, reduced dissolution loss, and simple impurity removal steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

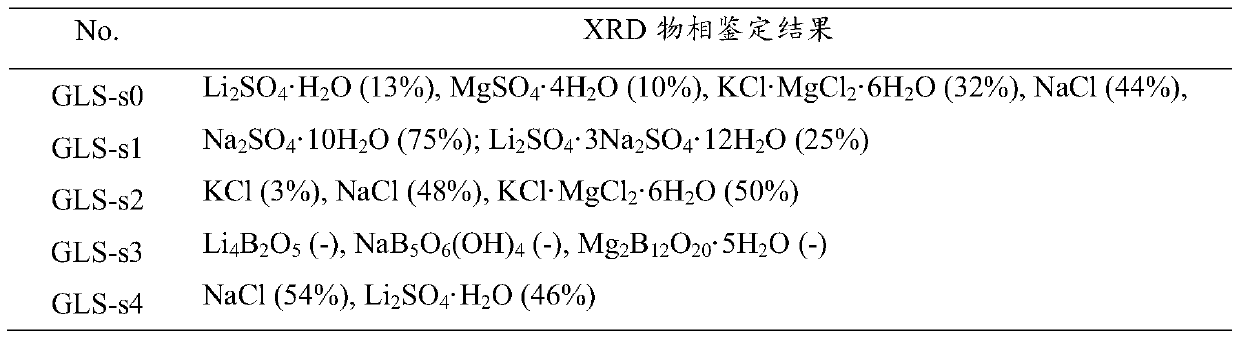

[0029] The coarse lithium sulfate ore used in the present invention utilizes the applicant's previous patented technology, see Chinese patent 201310124971.2, titled "A Method for Enriching and Separating Beneficial Elements in Sulfate Type Shielding Brine Using Natural Energy". The main steps include: evaporating the original brine of Chabocuo to the saturated state of sodium chloride, freezing nitrate in winter, and then evaporating in spring and summer to precipitate sodium chloride, potassium halite, carnallite, and epsom salt, and to control lithium in the brine. Ion concentration ≥ 6g / L for solid-liquid separation to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com