Method for efficient preparation of biomass based aromatic hydrocarbon

A technology based on biomass and aromatics, applied in chemical instruments and methods, hydrocarbon production from oxygen-containing organic compounds, bulk chemical production, etc., can solve the problems of long reaction steps, low yield of aromatics, low energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

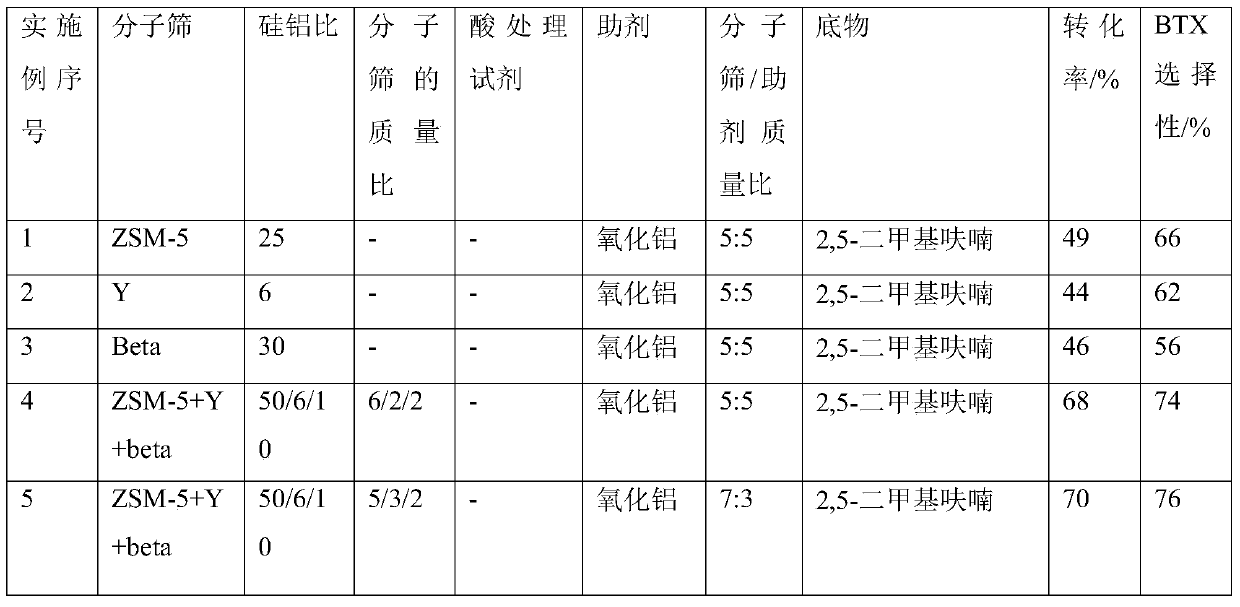

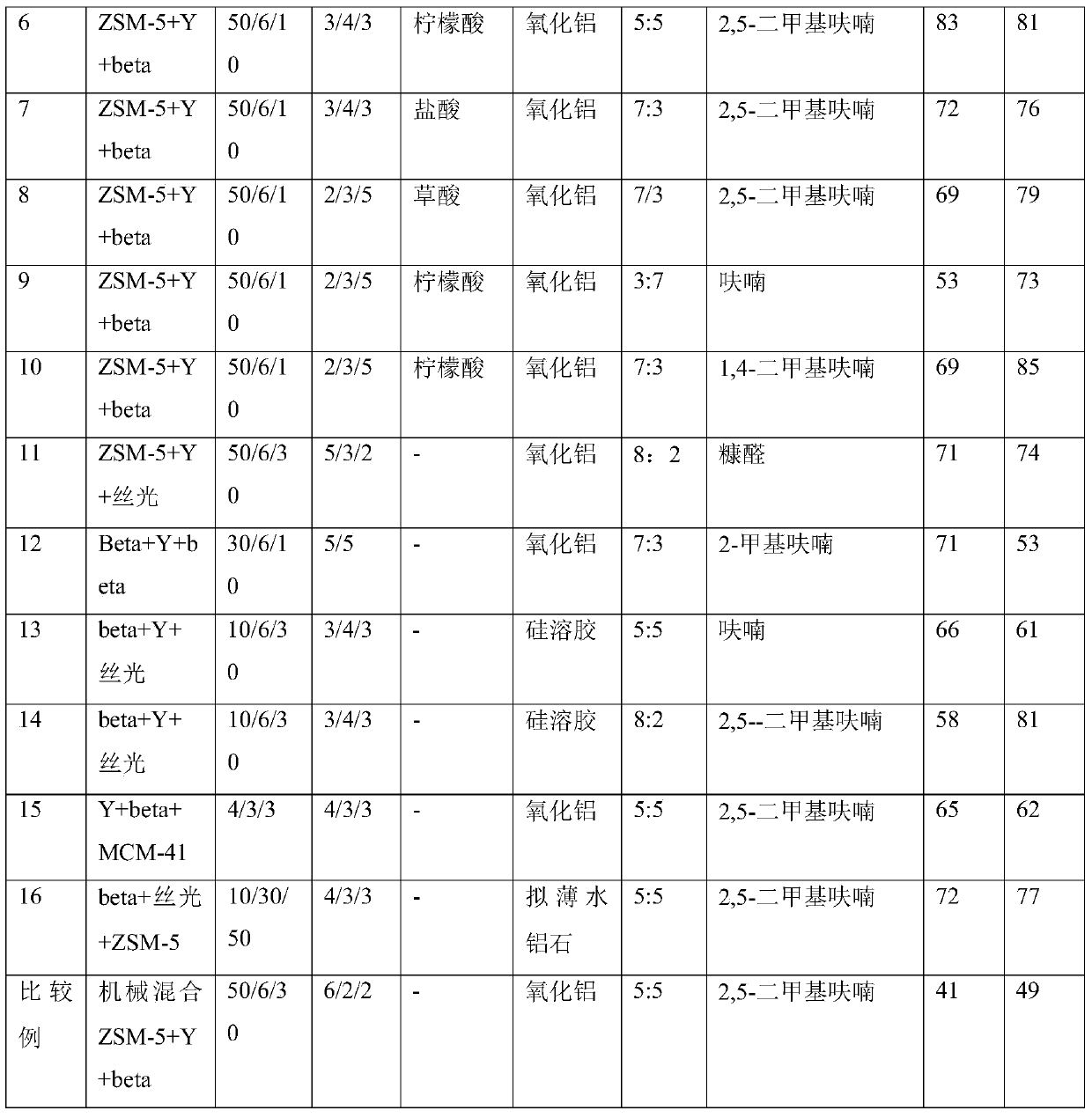

Examples

Embodiment 1

[0022] Weigh 35 grams of ZSM-5 with a silicon-aluminum ratio of 25 and mix it with 35 grams of γ-alumina additive, add 2.7 grams of scallop powder, and mix well. Then add 48 grams of nitric acid aqueous solution with a mass percentage of nitric acid of 5.5%, knead and shape, and extrude. The obtained catalyst precursor was dried at 120° C. for 8 hours and calcined at 500° C. for 2 hours to obtain a molecular sieve catalyst. Catalyst activity evaluation is carried out on a fixed bed, the reaction conditions are 3 grams of catalyst mass, 2,5-dimethylfuran as the reaction substrate, and 1.0 hour weight space velocity -1 , hydrogen pressure 1.0MPa, flow 50mlmin -1 , temperature 400°C. After the reaction, the conversion rate of the reaction substrate was 49%, and the selectivity of BTX was 66%.

Embodiment 2

[0024] Weigh 35 grams of Y molecular sieve with a silicon-aluminum ratio of 6 and mix with 35 grams of γ-alumina additive, add 2.7 grams of scallop powder, and mix well. Then add 48 grams of nitric acid aqueous solution with a mass percentage of nitric acid of 5.5%, knead and shape, and extrude. The obtained catalyst precursor was dried at 120° C. for 8 hours and calcined at 500° C. for 2 hours to obtain a molecular sieve catalyst. Catalyst activity evaluation is carried out on a fixed bed, the reaction conditions are 3 grams of catalyst mass, 2,5-dimethylfuran as the reaction substrate, and 1.0 hour weight space velocity -1 , hydrogen pressure 1.0MPa, flow 50mlmin -1 , temperature 400°C. After the reaction, the conversion rate of the reaction substrate was 44%, and the selectivity of BTX was 62%.

Embodiment 3

[0026] Weigh 35 grams of beta molecular sieve with a silicon-aluminum ratio of 30 and mix with 35 grams of γ-alumina additive, add 2.7 grams of scallop powder, and mix well. Then add 48 grams of nitric acid aqueous solution with a mass percentage of nitric acid of 5.5%, knead and shape, and extrude. The obtained catalyst precursor was dried at 120° C. for 8 hours and calcined at 500° C. for 2 hours to obtain a molecular sieve catalyst. Catalyst activity evaluation is carried out on a fixed bed, the reaction conditions are 3 grams of catalyst mass, 2,5-dimethylfuran as the reaction substrate, and 1.0 hour weight space velocity -1 , hydrogen pressure 1.0MPa, flow 50mlmin -1 , temperature 400°C. After the reaction, the conversion rate of the reaction substrate was 46%, and the selectivity of BTX was 56%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com