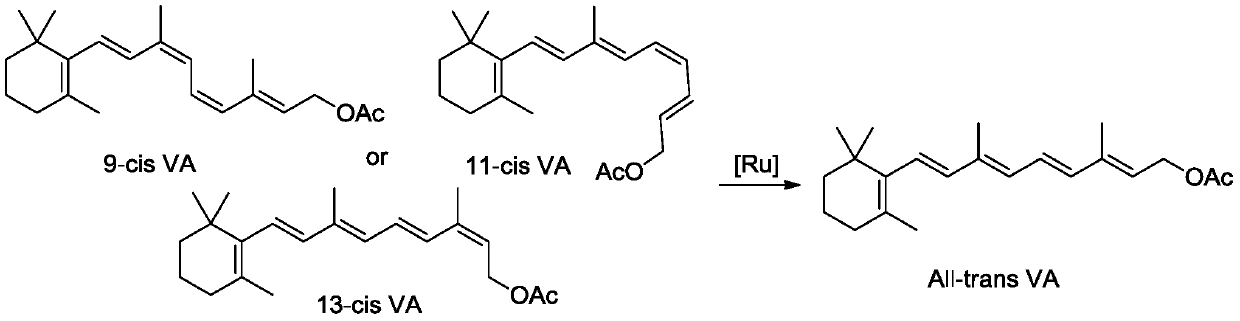

Method for catalyzing vitamin A isomerization with ruthenium catalyst

A ruthenium catalyst and isomerization technology, applied in the field of isomerization of vitamin A catalyzed by ruthenium catalysts, can solve the problems of photosensitizer residue, inability to convert cis-isomers, serious environmental pollution, etc., and achieve high isomerization efficiency, Improved recovery rate and low reaction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Auxiliary preparation:

[0044] (1) Preparation of urea-hydrogen peroxide complex: add 0.708kg 30% hydrogen peroxide (3eq.), 0.0125kg salicylic acid (0.1g / g) and 0.125kg urea (1.0eq.) to a 2L reactor, and keep warm at 5°C reaction. After the reaction is complete, cool down to -5°C, heat and stir for 3 hours, and then centrifuge. The centrifuged solid is rinsed with 0.375L petroleum ether (3ml / g), and the filter cake is a urea-hydrogen peroxide complex with a yield of 80% and a purity of 98%.

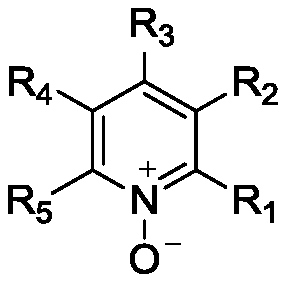

[0045] (2) The reaction process of preparing product 2-methoxypyridine-N-oxide compound: add 0.36L ethyl acetate (3ml / g) in 2L reactor, 0.155kg phthalic anhydride (1.0eq.), 0.109 kg 2-methoxypyridine (1.0 eq.). After the feeding is complete, raise the temperature of the system to 100°C, add 0.20kg of urea-hydrogen peroxide complex (2.0eq) to the system, and keep it warm for reaction; Turn blue again, then adjust the pH of the system to 9 with 20% sodium hydroxide, centrifuge, e...

Embodiment 2

[0051] Auxiliary preparation:

[0052] (1) Preparation of urea-hydrogen peroxide complex: add 0.708kg 30% hydrogen peroxide (3eq.), 0.0125kg salicylic acid (0.1g / g) and 0.125kg urea (1.0eq.) to a 2L reactor, and keep warm at 5°C reaction. After the reaction is complete, cool down to -5°C, heat and stir for 3 hours, and then centrifuge. The centrifuged solid is rinsed with 0.375L petroleum ether (3ml / g), and the filter cake is a urea-hydrogen peroxide complex with a yield of 80% and a purity of 98%.

[0053] (2) The reaction process of preparing the product 2-chloropyridine-N-oxide: add 0.36L ethyl acetate (3ml / g), 0.155kg phthalic anhydride (1.0eq.), 0.12kg to a 2L reactor 2-Chloropyridine (1.0 eq.). After the feeding is complete, raise the temperature of the system to 100°C, add 0.20kg of urea-hydrogen peroxide complex (2.0eq) to the system, and keep it warm for reaction; It turned blue again, then adjusted the pH of the system to 9 with 20% sodium hydroxide, centrifuged, ...

Embodiment 3

[0059] Auxiliary preparation:

[0060] (1) Preparation of urea-hydrogen peroxide complex: add 0.708kg 30% hydrogen peroxide (3eq.), 0.0125kg salicylic acid (0.1g / g) and 0.125kg urea (1.0eq.) to a 2L reactor, and keep warm at 5°C reaction. After the reaction is complete, cool down to -5°C, heat and stir for 3 hours, and then centrifuge. The centrifuged solid is rinsed with 0.375L petroleum ether (3ml / g), and the filter cake is a urea-hydrogen peroxide complex with a yield of 80% and a purity of 98%.

[0061] (2) The reaction process of preparing product 4-picoline-N-oxide: add 0.36L ethyl acetate (3ml / g) in 2L reactor, 0.155kg phthalic anhydride (1.0eq.), 0.093 kg 4-picoline (1.0 eq.). After the feeding is complete, raise the temperature of the system to 100°C, add 0.20kg of urea-hydrogen peroxide complex (2.0eq) to the system, and keep it warm for reaction; Turn blue again, then adjust the pH of the system to 9 with 20% sodium hydroxide, centrifuge, extract, and combine and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com