Crystalline silicon solar cell without Ag main grid line and manufacturing process therefor

A technology for solar cells and manufacturing processes, applied in sustainable manufacturing/processing, circuits, photovoltaic power generation, etc., can solve problems such as failure to solve the problem of single-cell battery testing, enhance the passivation of aluminum back field, and improve conversion efficiency , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

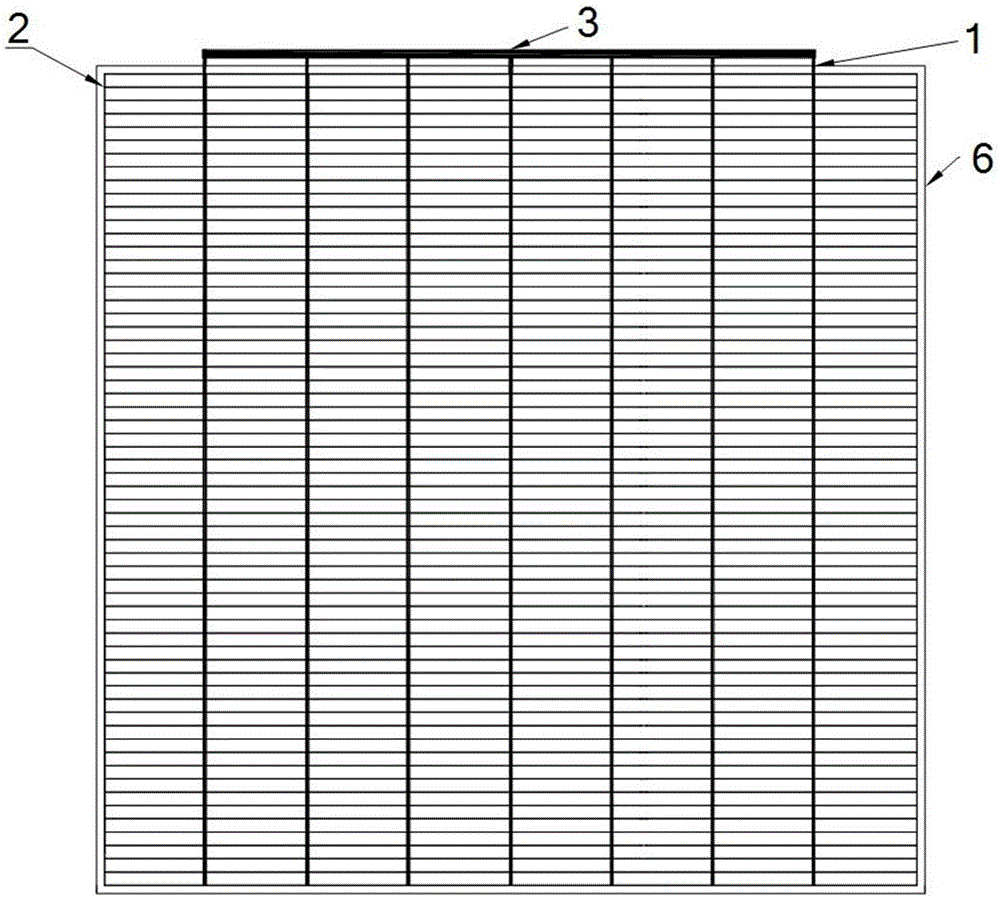

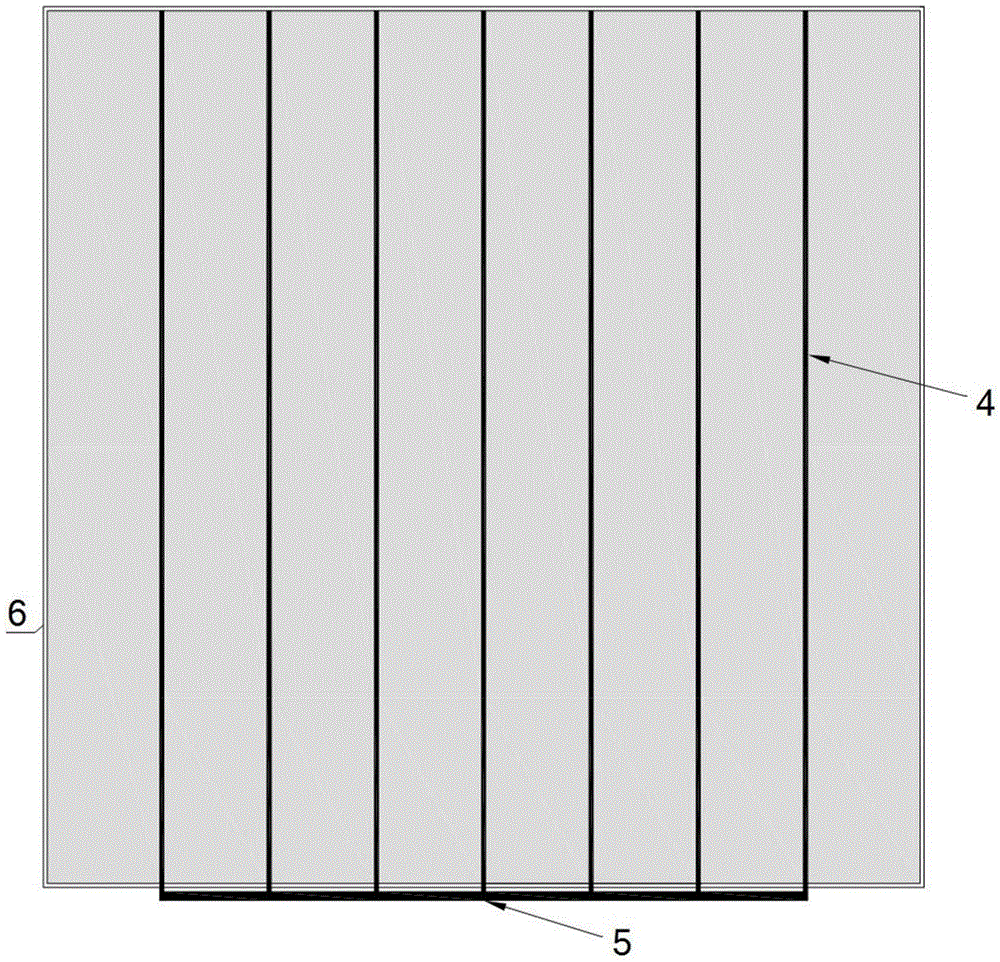

[0039] According to the trial production process of P-type polycrystalline batteries, the batteries only need to be printed and sintered by the back electric field and the front Ag sub-gate electrode, and a batch of P-type 156mm polycrystalline batteries without busbars are trial-produced, and a batch of traditional battery control groups are set; first press According to the technical solution described in the content of the present invention, 7 busbar lines of copper-tin solder strips with a width of 0.7mm and 3mm beyond the battery are evenly fixed on the front and back sides of the battery without busbar; It is a 1.5mm copper-tin ribbon, which is used for battery test contact wires and battery connection wires during component packaging; then the fixed copper-tin ribbon main grid polycrystalline battery is cured in an oven at 140°C 25s, forming an Ag-free busbar polycrystalline cell. Finally, compare the efficiency, electrical performance and other data of the Ag-free busb...

Embodiment 2

[0041] According to the trial production process of P-type monocrystalline cells, the cells only need to be printed and sintered in the back electric field and the front Ag sub-gate electrode, and a batch of P-type 156mm single crystal cells without busbars are trial-produced, and a batch of traditional battery control groups are set up; first press In the technical solution described in the content of the present invention, 7 busbar lines of copper-tin soldering strips with a width of 0.7mm and 3mm beyond the battery are evenly fixed on the front and back sides of the battery without busbar; Copper-tin solder strip with a width of 1.5mm is used for battery test contact wires and battery connection wires during component packaging; then place the fixed copper-tin solder strip main grid polycrystalline battery in an oven at 140°C Curing for 25s to form an Ag-free busbar polycrystalline cell. Finally, compare the efficiency, electrical performance and other data of the Ag-free b...

Embodiment 3

[0043] According to the trial production process of N-type monocrystalline double-sided batteries, the batteries only need to be printed and sintered with Ag sub-gate electrodes on the back and front, and a batch of N-type 156mm single-crystalline double-sided batteries without busbars will be trial-produced, and a batch of traditional battery control groups will be set up. ; First, according to the technical scheme described in the contents of the present invention, evenly fix 7 copper-tin solder strip busbar lines with a width of 0.7mm and 3mm beyond the battery part on the front and back sides of the battery without busbar; secondly, on the busbar Weld the copper-tin ribbon with a grid width of 1.5mm at the terminal point, which is used for the battery test contact wire and the battery connection wire during component packaging; then place the polycrystalline battery with the fixed copper-tin ribbon main grid at 140°C Cured in an oven for 25s to form Ag-free busbar polycryst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com