Light source assembly for projection system

A light source component and projection system technology, applied in optics, instruments, projection devices, etc., can solve problems such as light waste, inability to enter the system, and bulb brightness attenuation, and achieve the effects of improving light efficiency, increasing light efficiency, and increasing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

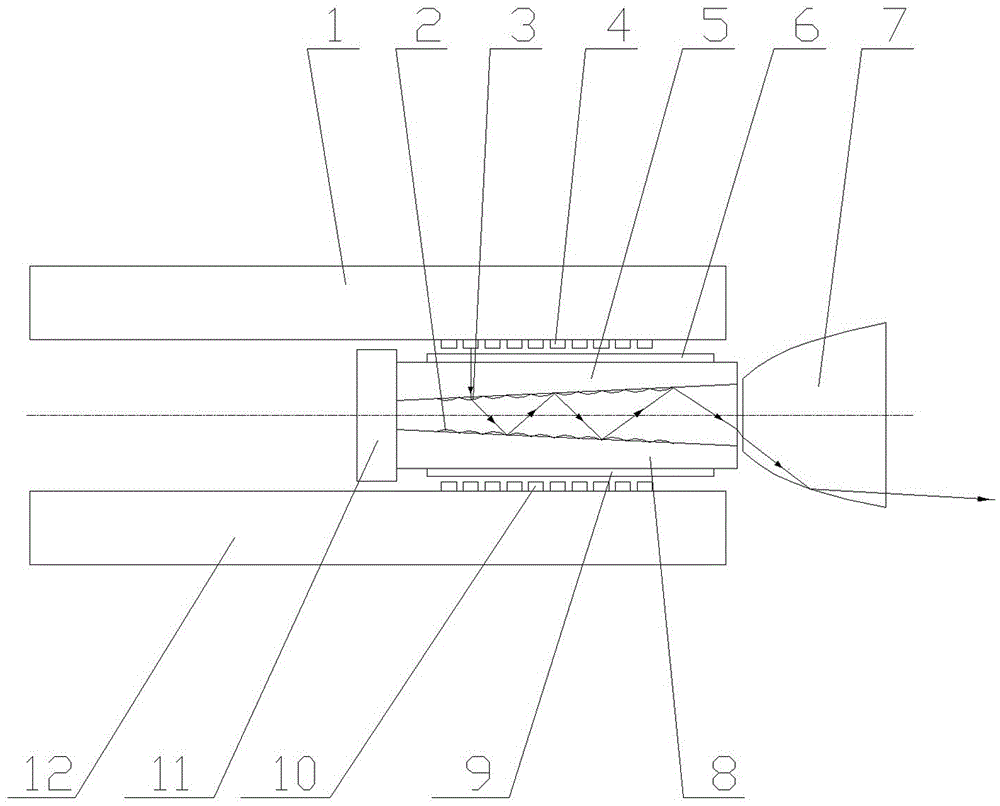

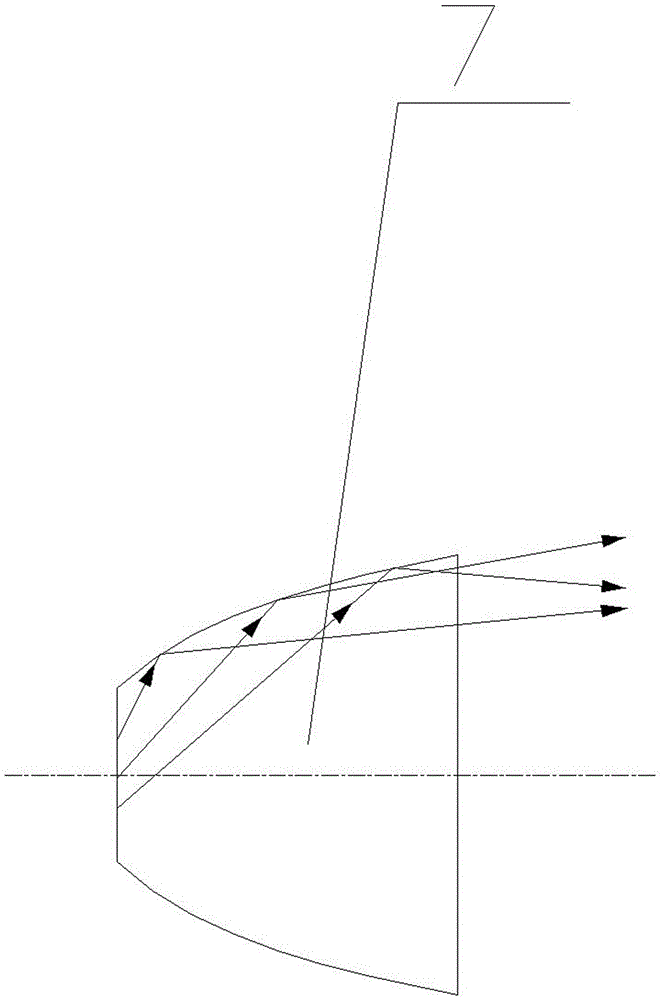

[0031] Such as figure 1 As shown, the light source assembly proposed by the present invention includes: a hollow light pipe inside and light-emitting elements arranged outside the left and right sides of the light pipe. For ease of description, the light-emitting element arranged outside the left side of the light guide is the left light-emitting element 4, the light-emitting element arranged outside the right side of the light guide is called the right light-emitting element 10, and the left light-emitting element 4 is arranged on the left circuit board 1 , the right light emitting element 10 is arranged on the right circuit board 12 .

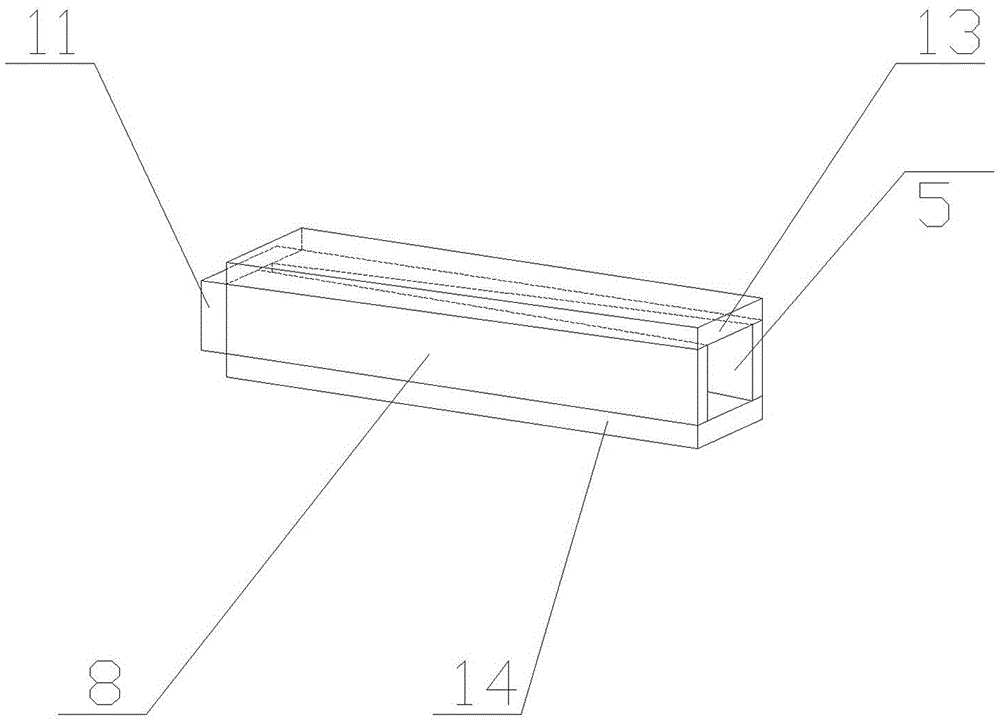

[0032] Such as figure 1 , 2 As shown, the light guide is formed by bonding the left reflector 5, the right reflector 8, the upper reflector 13, the lower reflector 14 and the rear reflector 11. The inner surfaces of all reflectors are coated with a layer of reflective film. The inner surfaces of the reflective sheet 5 and the right reflect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com