Warm-keeping type moisture absorbing and sweat releasing felt fabric with bionic structure

A plush fabric and warm-keeping technology, which is applied in the field of warm-keeping moisture-absorbing and sweat-wicking plush fabrics, can solve the problems of non-continuity of the moisture-conducting channel of the fabric, reduce the moisture-conducting performance of the fabric, and prevent weaving by ordinary looms. Effective conduction and rapid volatilization, improved thermal performance and moisture permeability, and improved moisture conduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

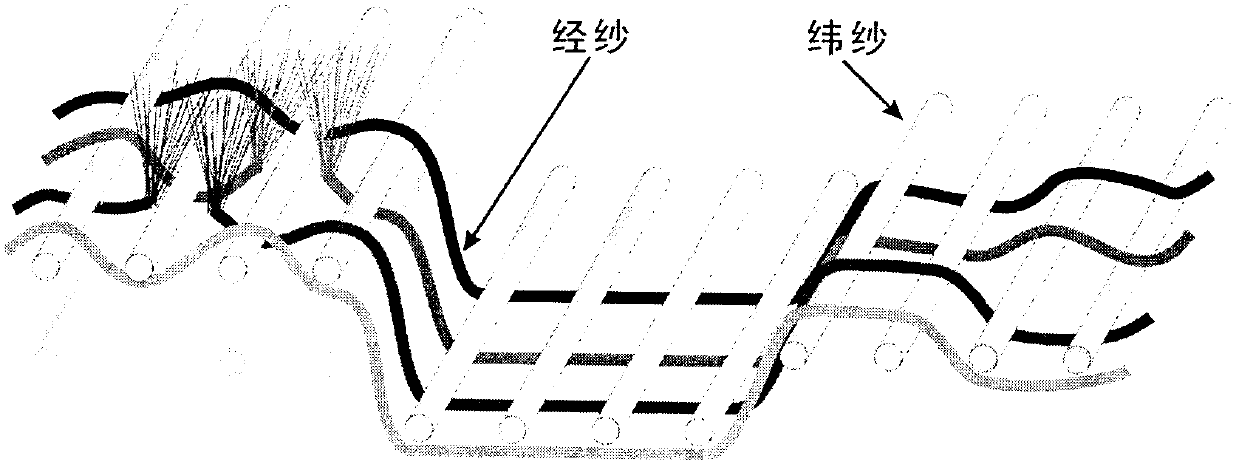

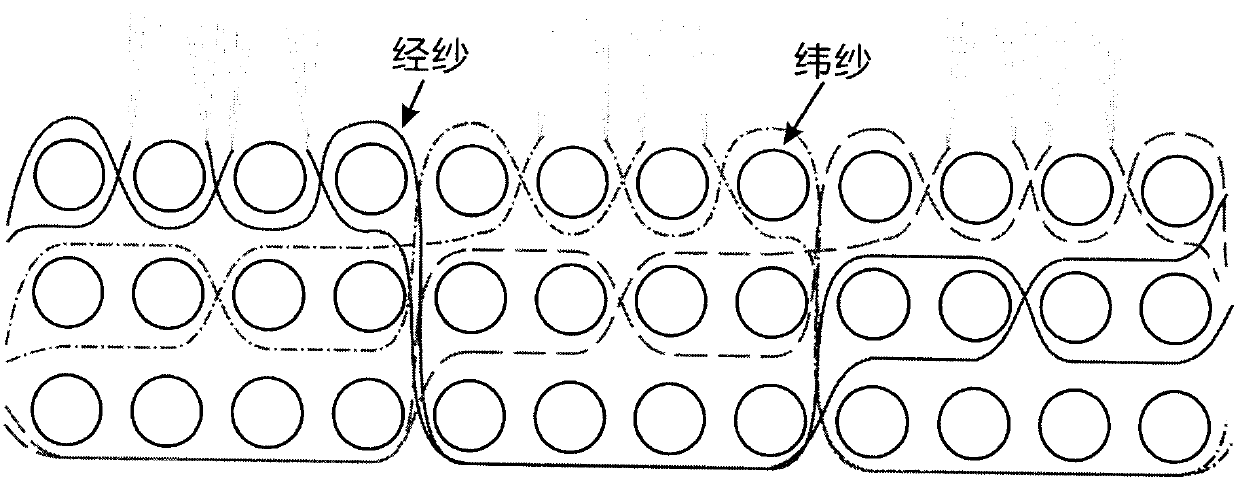

[0026] Use full wool 25tex×2 yarn, according to figure 1 The structure shown is weaved on the machine, and the machine process is as follows: the warp density is 450 threads / 10cm, the weft density is 300 threads / 10cm, every 6 wool warp yarns and every 6 ground warp yarns are threaded into healds at intervals, and the reed number is No. 75. The number of reeds is 6 / reed, and the height of the 3mm raising bar is used for weaving, and the pile fabric of the lower machine is cut and loosened.

Embodiment 2

[0028] Use full wool 25tex×2 yarn, according to figure 1 The structure shown is weaved on the machine, and the machine process is as follows: the warp density is 450 threads / 10cm, the weft density is 300 threads / 10cm, every 6 wool warp yarns and every 6 ground warp yarns are threaded into healds at intervals, and the reed number is No. 75. The number of reeds is 6 / reed, and the height of the 6mm raising bar is used for weaving, and the pile fabric of the lower machine is cut and loosened.

Embodiment 3

[0030] The warp yarn is made of wool 25tex×2 yarn, the first layer of weft yarn is made of wool 25tex×2 yarn, the second layer is made of cotton 25tex×2 yarn, and the third layer is made of polyester 25tex×2 yarn. figure 1 The structure shown is weaved on the machine, and the machine process is as follows: the warp density is 450 threads / 10cm, the weft density is 300 threads / 10cm, every 6 wool warp yarns and every 6 ground warp yarns are threaded into healds at intervals, and the reed number is No. 75. The number of reeds is 6 / reed, and the height of the 3mm raising bar is used for weaving, and the pile fabric of the lower machine is cut and loosened.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com