LED chip with electrostatic protection function and production method thereof

A LED chip and electrostatic protection technology, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problems of poor high-voltage electrostatic resistance, insufficient high-voltage resistance of LED chips, scrapping, etc., and achieve the effect of preventing burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

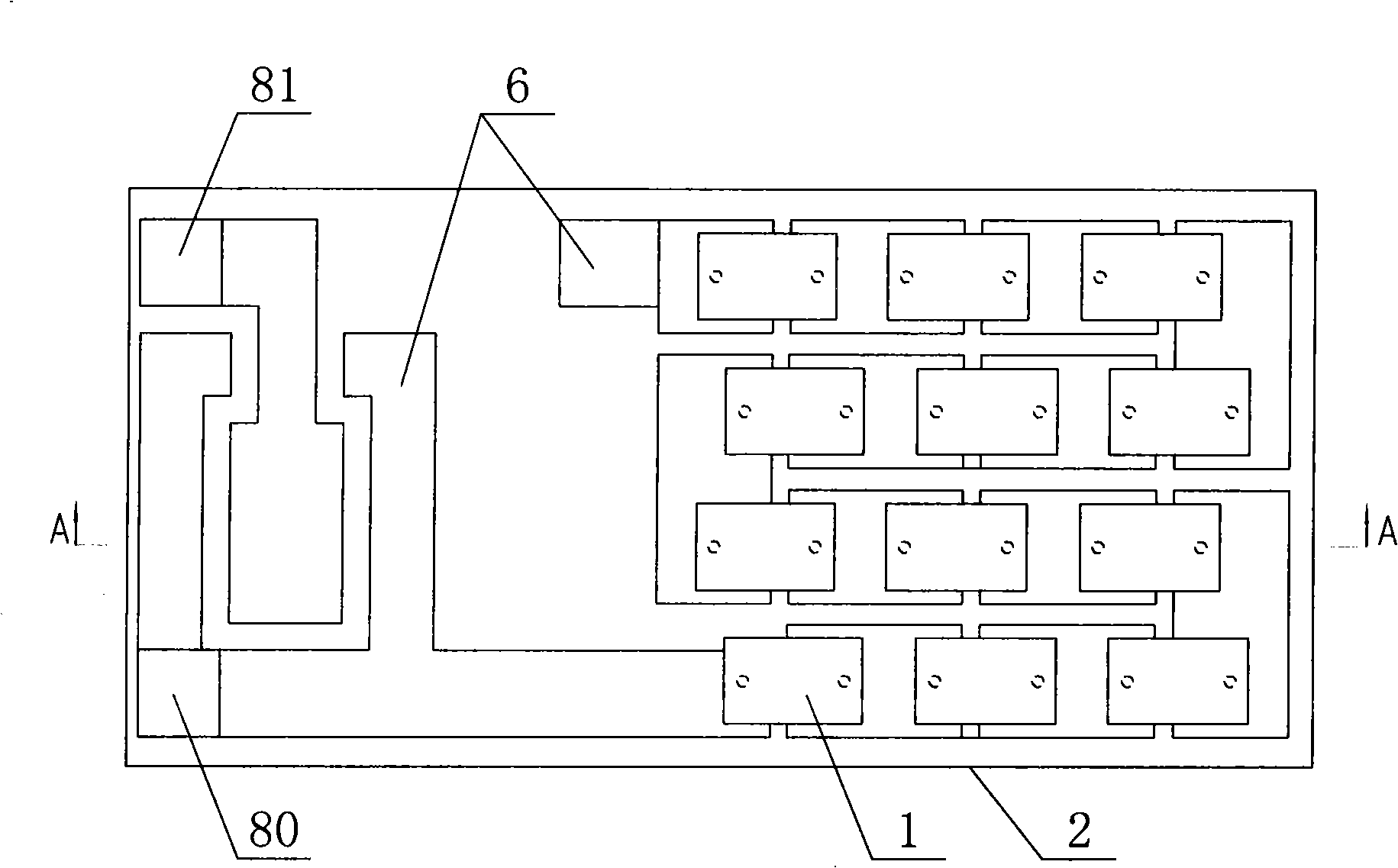

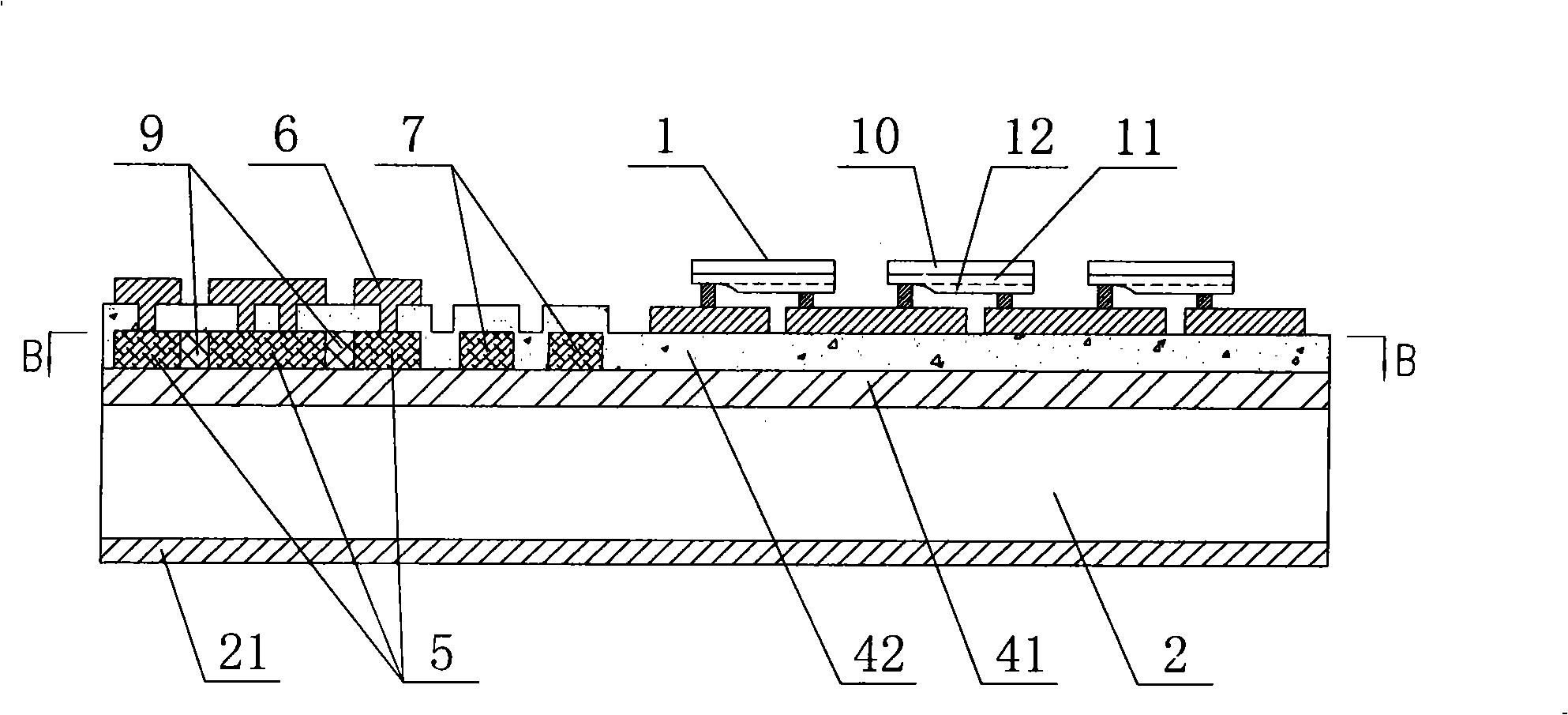

[0054] Such as Figure 1 ~ Figure 4 As shown, the LED chip with electrostatic protection function of the present embodiment includes 12 LED bare chips 1 and silicon substrate 2, and the LED bare chip 1 is a double-electrode chip, and the LED bare chip 1 includes sapphire (Al 2 o 3) substrate 10 and gallium nitride (GaN) N-type epitaxial layer 11, P-type epitaxial layer 12, certainly, described substrate 10 also can be the substrate of other materials such as silicon carbide (SiC), described silicon substrate 2 is a P-type silicon substrate, on which a heat-conducting insulating layer I 41 is formed, and the heat-conducting insulating layer I 41 is composed of a silicon nitride layer. The thermal conductivity of silicon nitride is very high, and its thermal conductivity is higher than The general heat conduction adhesive is more than 100 times higher, and the thickness of the heat conduction insulating layer I 41 is thin simultaneously, so thermal conductivity is good, can pla...

Embodiment 2

[0067] Such as Figure 5 ~ Figure 8 As shown, the difference between this embodiment and Embodiment 1 is that the LED bare chip 1 in the LED chip with electrostatic protection function of this embodiment is a single-electrode chip, and the LED bare chip 1 includes gallium arsenide (GaAs) Substrate 10 and N-type epitaxial layer 11, P-type epitaxial layer 12, certainly, described substrate 10 also can be the substrate of other materials such as silicon carbide (SiC), and each described LED bare chip 1 is loaded on each described on and through the metal layer 6 to form a full-series LED circuit, the substrate 10 is glued on the metal layer 6 with silver paste or tin, and the electrode contacts of the LED bare chip 1 pass through A metal wire is welded on an adjacent metal layer 6 . A layer of N+ diffusion layer 3 is diffused inwardly from the front side of the silicon substrate 2 , and the heat conducting and insulating layer I 41 is grown on the N+ diffusion layer 3 . There a...

Embodiment 3

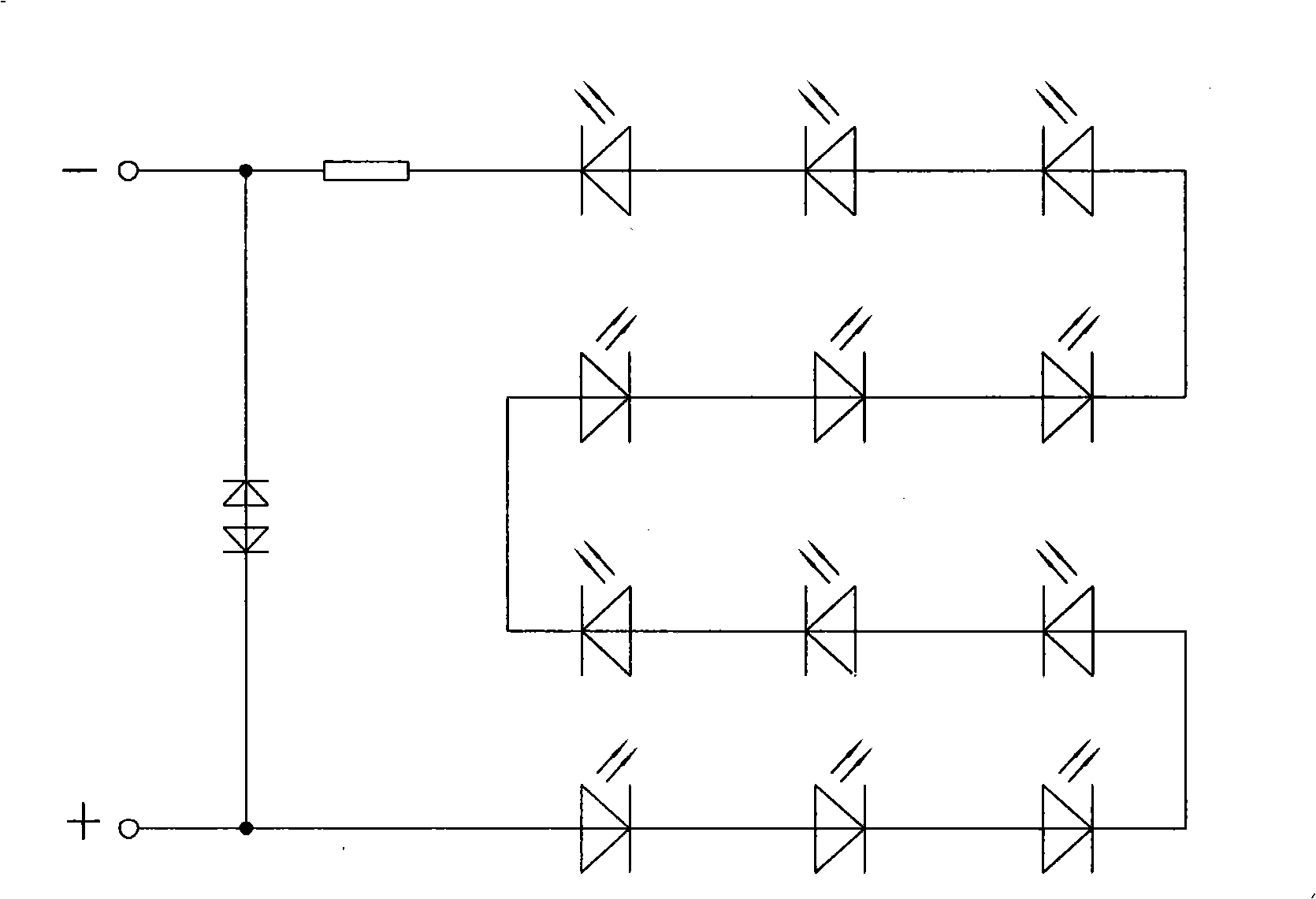

[0075] Such as Figure 9 ~ Figure 12 As shown, the difference between this embodiment and the second embodiment is that: the LED bare chip 1 is a double-electrode chip, and the substrate 10 is aluminum oxide (sapphire, Al 2 o 3 ) substrate, the P-type epitaxial layer 12 and the N-type epitaxial layer 11 are respectively welded to two adjacent separated metal layers 6 through two metal wires. There are two resistance areas 7, one end of the two resistance areas 7 are respectively connected to the anode contact 80 and the cathode contact 81 in ohm, and the other ends of the two resistance areas 7 are connected in series In the LED bare chip 1, each of the electrostatic protection diode regions is formed with a polarity of N + PN + PN + Zener diode groups, two of the Zener diode groups are connected in parallel between the positive and negative poles on both sides of the delay on-resistance formed by the two resistance regions 7, which has a delay to the LED chip When the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com